Operating device and method for cleaning near-well polluted area of coalbed methane well

A technology for coalbed methane wells and polluted areas, which is applied in wellbore/well components, earth-moving drilling, flushing wellbore, etc., to achieve the effects of increased input and output, increased permeability, and strong ash-carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

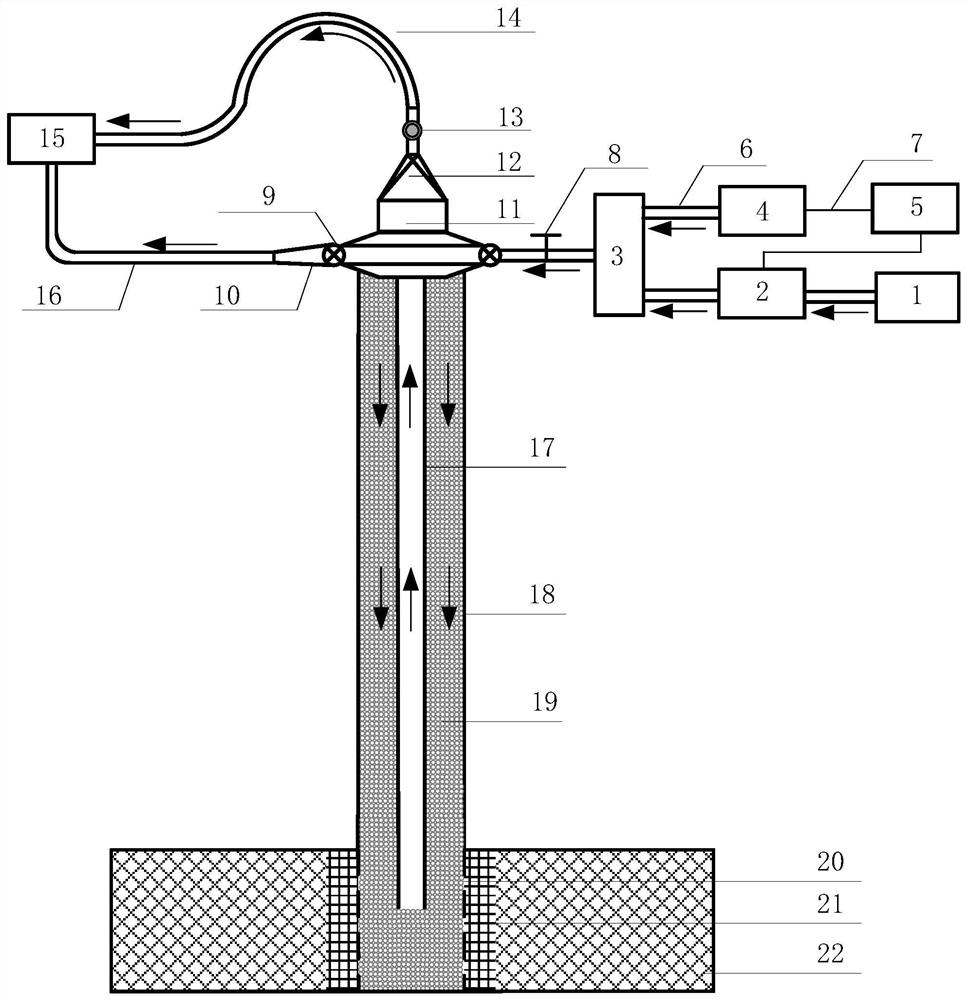

[0022] Such as figure 1 As shown, the operating device for cleaning the polluted area near the well of the coalbed methane well includes: liquid distribution tank 1, pump truck 2, foam generator 3, nitrogen generating train unit 4, command vehicle 5, blowout preventer 11, fluid channel conversion Device 12, cock valve 13, well flushing and flowback pipe 14, flowback fluid storage tank 15, well flushing operation string 17; the pump truck 2 is connected to the liquid distribution tank 1 and the foam generator 3 through the pipeline 6, and the pump truck 2. Pump the well flushing fluid in the liquid distribution tank 1 into the foam generator 3; the foam generator 3 is a three-way structure, the first port is connected to the pump truck 2 through the pipeline 6, and the second port is connected to the nitrogen generator unit 4 through the pipeline connected, the third port is connected with the injection gate valve 8 through the pipeline; the nitrogen making train group 4 is con...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap