System and method for flushing coal ash in coal-bed gas well by using nitrogen foam flushing fluid

A coalbed methane well and nitrogen foam technology is applied in the field of fly ash system to achieve the effects of small water consumption, strong ash carrying capacity and increased permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

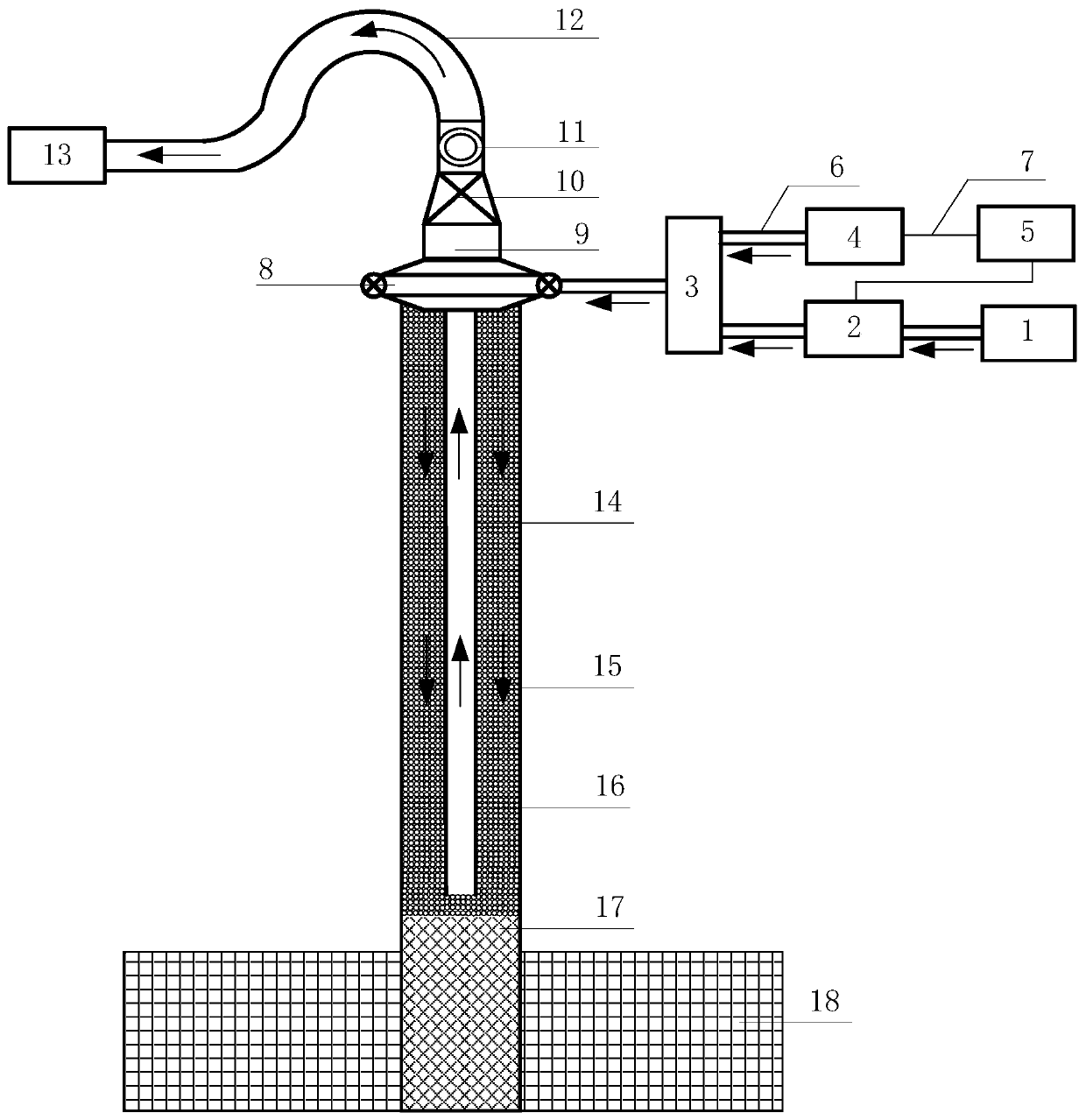

[0022] Such as figure 1 As shown, the construction operation diagram of the system for flushing fly ash in coalbed methane wells with nitrogen foam well flushing fluid, including: liquid distribution tank 1, pump truck 2, foam generator 3, nitrogen generating train unit 4, command vehicle 5, well control Blowout gate valve 8, blowout preventer 9, fluid channel conversion device 10, cock valve 11, flowback pipe 12, flowback liquid storage tank 13, coalbed methane well bore 15, well washing operation string 14; coalbed methane well bore 15 is a Vertical well, with a well-controlled blowout gate valve installed on the top, which is used to release the liquid in the coalbed methane reservoir 18 during the blowout and flushing operation; the bottom of the coalbed methane wellbore is located in the coalbed methane reservoir 18, and pulverized coal is accumulated in the middle and lower part of the coalbed methane wellbore Ash 17; nitrogen foam well flushing fluid 16 is injected from...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap