Noise testing device for speed reducer

A test device, reducer technology, applied in the direction of measuring device, testing of mechanical components, testing of machine/structural components, etc., can solve the problems of inaccurate test results, slow test speed, waste of labor and labor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

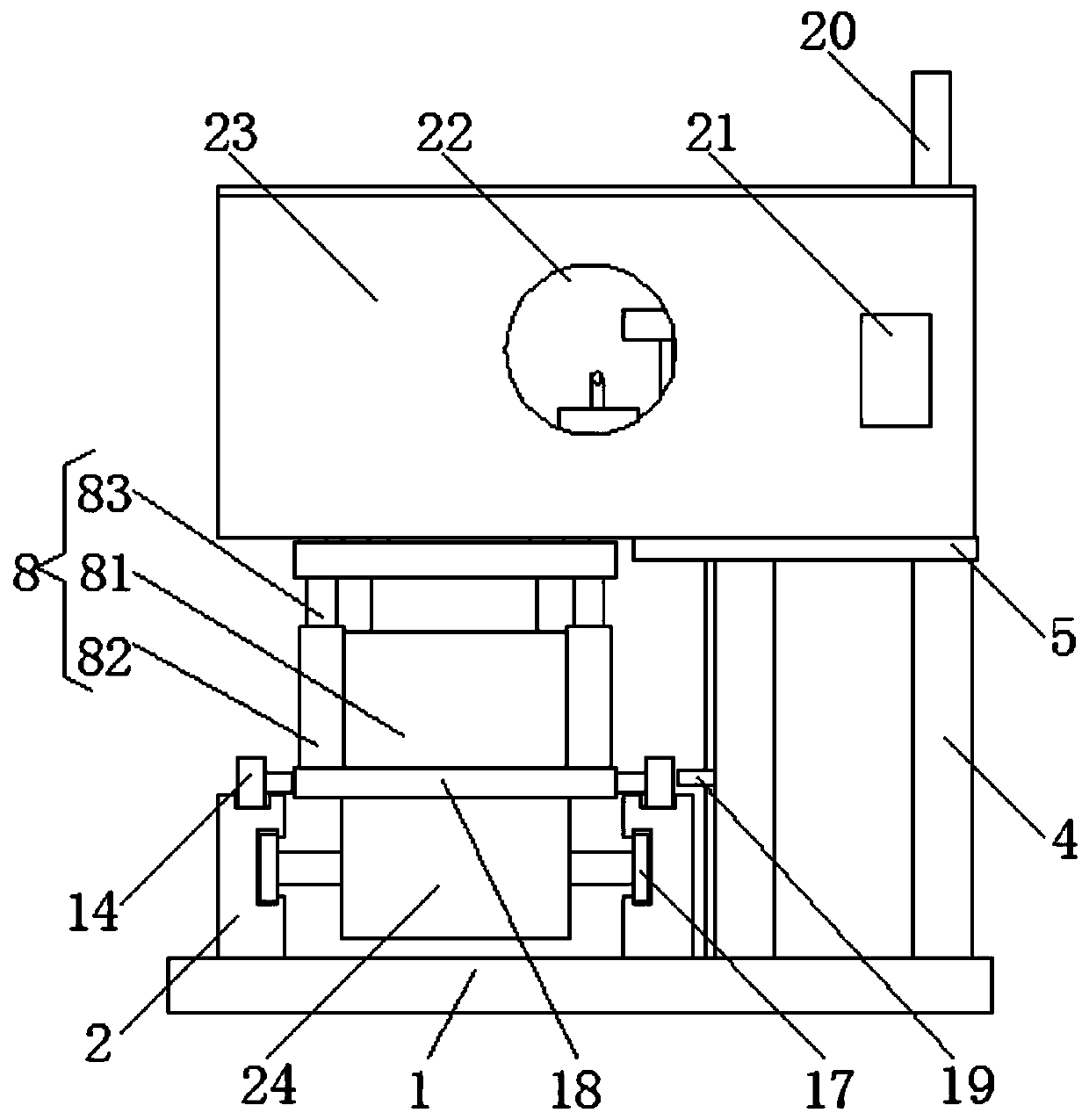

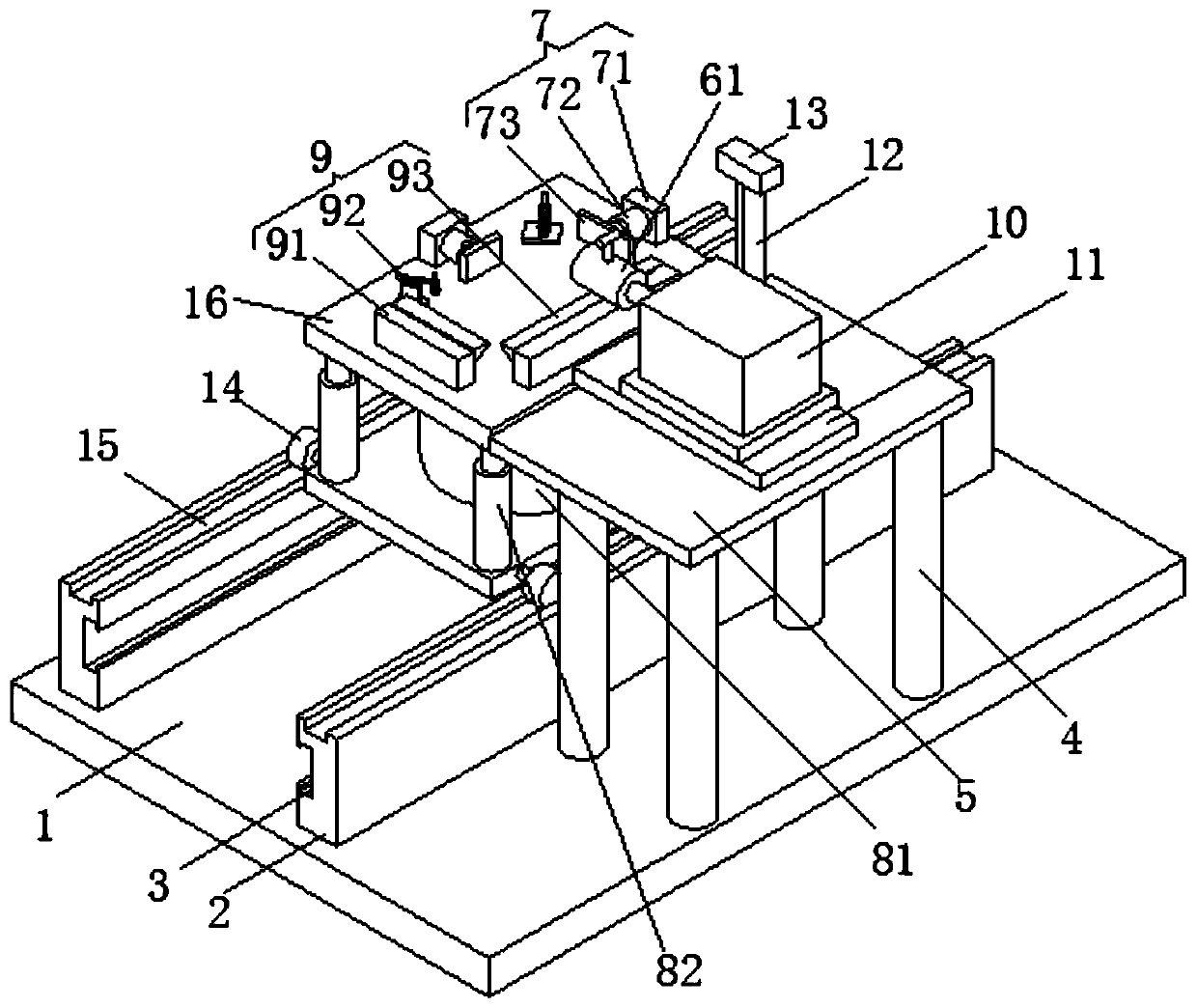

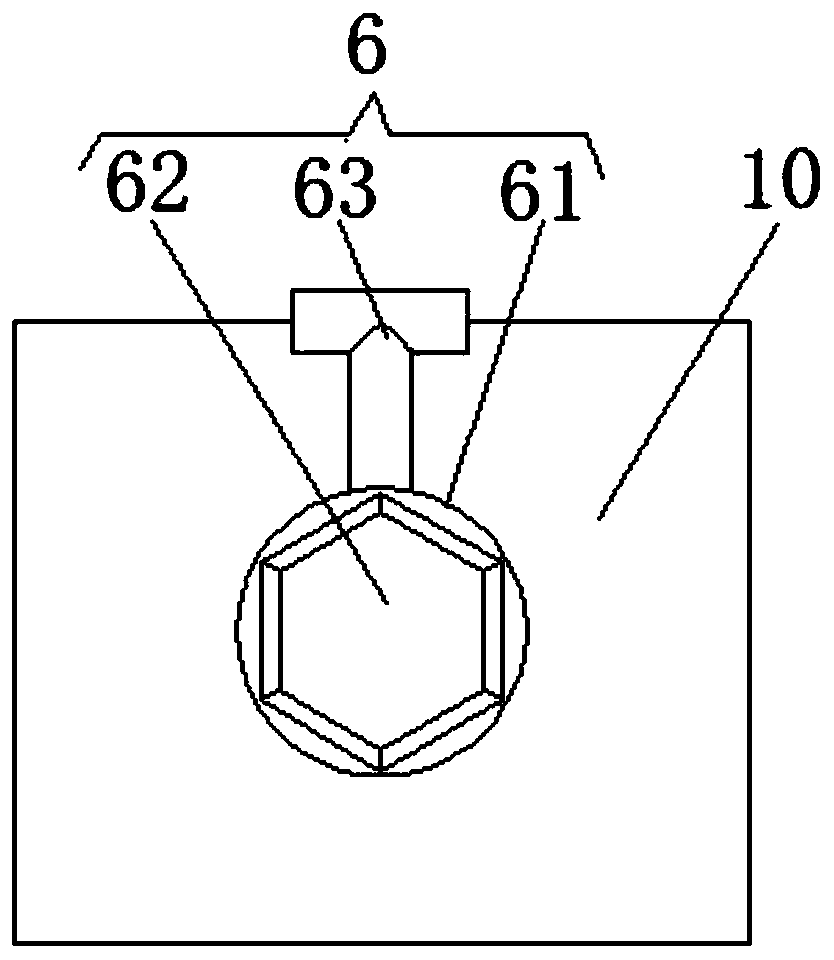

[0021]Embodiment 1: A noise test device for a reducer, including a bottom plate 1, a connecting unit 6, a lifting unit 8, a lifting plate 16 and a biaxial motor 24, and two symmetrically distributed guide rails 2 are arranged on the left side of the upper surface of the bottom plate 1, The inner side of the guide rail 2 is provided with a rack groove 3, and the right end of the upper surface of the bottom plate 1 is provided with four symmetrically distributed legs 4, the upper surfaces of the legs 4 are connected with the lower surface of the table 5, and the upper surface of the table 5 is aligned with the straight line The lower surface of the stator of the motor 11 is fixedly connected, and the upper surface of the mover of the linear motor 11 is fixedly connected with the test motor 10. The connecting unit 6 includes a connecting cylinder 61, a hexagon socket 62 and a locking bolt 63. The right end of the connecting cylinder 61 is connected to the testing motor. The end of...

Embodiment 2

[0024] The difference between this embodiment and Embodiment 1 is:

[0025] In this embodiment, the lifting unit 8 includes a second electric push rod 81, a sleeve 82 and a guide column 83, the lower end of the second electric push rod 81 is fixedly connected with the upper surface of the moving plate 18, and the upper end of the second electric push rod 81 Fixedly connected with the lower surface of the lifting plate 16, the sleeve 82 has four and is symmetrically arranged on the four corners of the upper surface of the moving plate 18, the upper end of the guide column 83 is welded with the lower surface of the lifting plate 16, and the outer arc surface of the guide column 83 is connected to the lower surface of the lifting plate 16. The inner arc surface of the corresponding sleeve 82 is slidingly connected, and the second electric push rod 81 is electrically connected to the PLC controller 21 .

[0026] Specifically, it is set in this way, the second electric push rod 81 ...

Embodiment 3

[0028] The difference between this embodiment and Embodiment 1 is:

[0029] In this embodiment, the positioning unit 7 includes a first support plate 71, a first electric push rod 72 and a push plate 73. There are two first support plates 71 and they are respectively arranged on the left end and the rear end of the upper surface of the lifting plate 16. An electric push rod 72 is fixedly connected to the side of the corresponding first support plate 71 , a push plate 73 is fixedly connected to the end of the corresponding first electric push rod 72 , and the first electric push rod 72 is connected to the PLC controller 21 .

[0030] Specifically, it is set in this way, the reducer is placed on the upper surface of the lifting plate 16, the first electric push rod 72 is opened by the PLC controller 21, the first electric push rod 72 pushes the push plate 73 to move, and the push plate 73 pushes the speed reducer. The movement of the base makes the base of the reducer contact wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com