A kind of double-layer composite proton conductor material and its preparation method

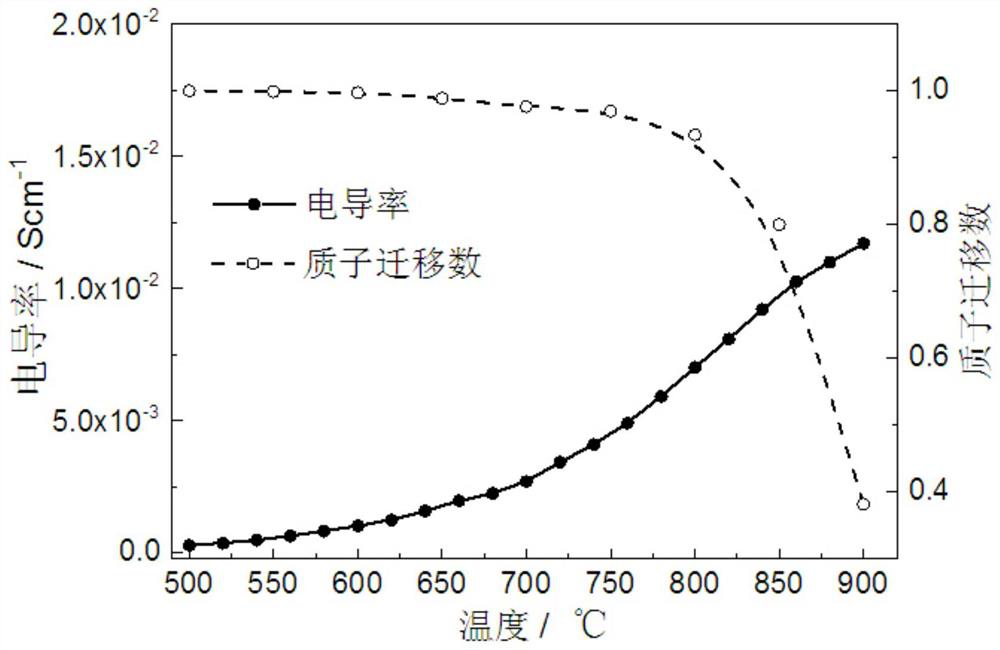

A proton conductor, double-layer composite technology, applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, electrical components, etc. Hole conduction and other problems, to achieve the effect of improving proton conductivity, improving corrosion resistance, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The double-layer composite proton conductor material is a double-layer structure composed of a matrix part and a coating part, and the molecular formula of the matrix part is A 1-y A' y B 1-z B' z o 3-α , the formula A of the coating part 3 (B' 1+x B″ 2-x )O 9-γ ;

[0038] A 1-y A' y B 1-z B' z o 3-α The A element is Ba, the B element is Ce, the B' element is Y, y=0 (no element A'), z=0.1, and the value of 3-α varies with AB 1-z B' z o 3-α The total valence state balance;

[0039] A 3 (B' 1+x B″ 2-x )O 9-γ for Ba 3 (Ca 1+x Nb 2-x )O 9-γ , x=0.18; the value of 9-γ varies with A 3 (B' 1+x B″ 2-x )O 9-γ The total valence state balance;

[0040] The thickness ratio of the coating part to the substrate part is 0.1;

[0041] The preparation method is:

[0042] Prepare BaCO 3 As the first A raw material, prepare CaCO 3 As the first B' raw material, prepare Nb 2 o 5 As the B" raw material; the first A raw material, the first B' raw material and...

Embodiment 2

[0049] In double-layer composite proton conductor materials, A 1-y A' y B 1-z B' z o 3-α The A element is Ca, the A' element is K, the B element is Sn, the B' element is Nd, y=0.2, z=0.3;

[0050] A 3 (B' 1+x B″ 2-x )O 9-γ for Ba 3 (Sr 1+x Nb 2-x )O 9-γ , x=0.22;

[0051] The thickness ratio of the coating part to the substrate part is 0.01;

[0052] Method is with embodiment 1, and difference is:

[0053] (1) The mixed powder I is pressed at a pressure of 10MPa and calcined at 1000°C for 20 hours;

[0054] (2) In the mixed powder I, the molar ratio A:B':B"=3:1.22:1.78;

[0055] (3) The compression pressure of the mixed powder II is 10MPa, and it is calcined at 800°C for 20 hours;

[0056] (4) In the mixed powder II, the molar ratio A:A':B:B'=0.8:0.2:0.7:0.3;

[0057] (5) The pressing pressure of calcined material II is 300 MPa; the calcined material I is covered on the substrate blank to form a coating by laser deposition method to obtain a double-layer blank...

Embodiment 3

[0060] In double-layer composite proton conductor materials, A 1-y A' y B 1-z B' z o 3-α The A element is Sr, the A' element is Na, the B element is Hf, the B' element is Sm, y=0.3, z=0.2;

[0061] A 3 (B' 1+x B″ 2-x )O 9-γ for Ba 3 (Sr 1+x Ta 2-x )O 9-γ , x=0.31;

[0062] The thickness ratio of the coating part to the substrate part is 0.02;

[0063] Method is with embodiment 1, and difference is:

[0064] (1) The mixed powder I is pressed at a pressure of 6MPa and calcined at 1000°C for 19 hours;

[0065] (2) In the mixed powder I, the molar ratio A:B':B"=3:1.31:1.69;

[0066] (3) The compression pressure of the mixed powder II is 6MPa, and it is calcined at 900°C for 19 hours;

[0067] (4) In the mixed powder II, the molar ratio A:A':B:B'=0.7:0.3:0.8:0.2;

[0068] (5) The pressing pressure of calcined material II is 80MPa; the calcined material I is covered on the substrate blank to form a coating by using the magnetron sputtering method, and a double-layer b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com