A noise-reducing double-sided sound-absorbing barrier for transformers

A transformer and noise reduction technology, applied in the direction of transformer/inductor noise damping, etc., can solve the problem of rare two transformers, and achieve the effect of high sound absorption efficiency, noise reduction, and improvement of operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

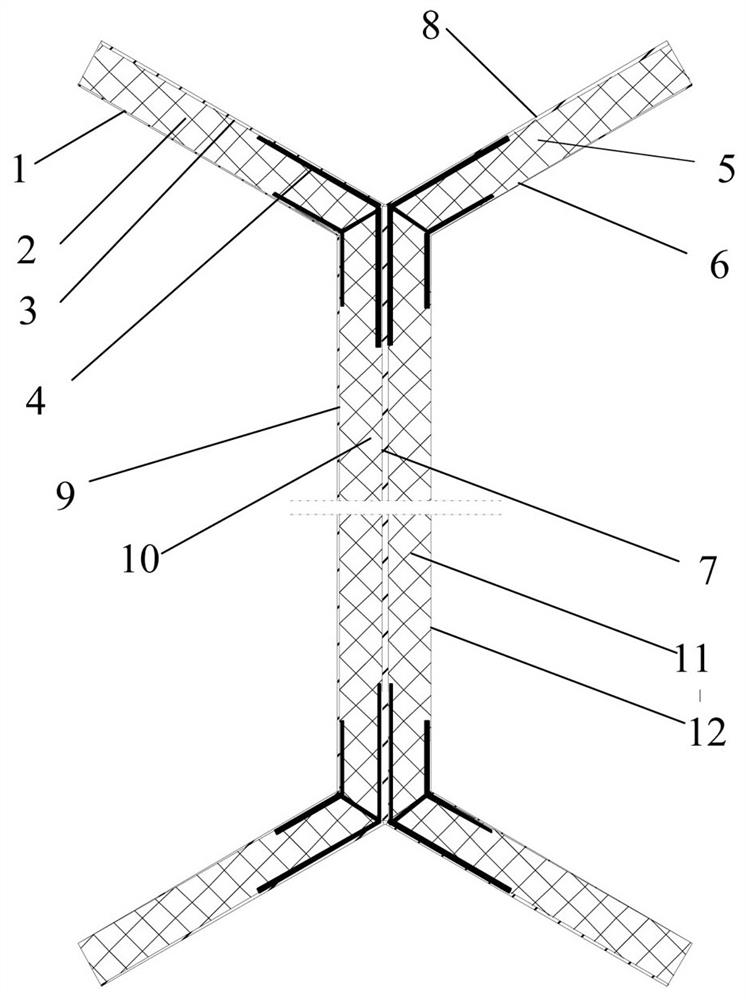

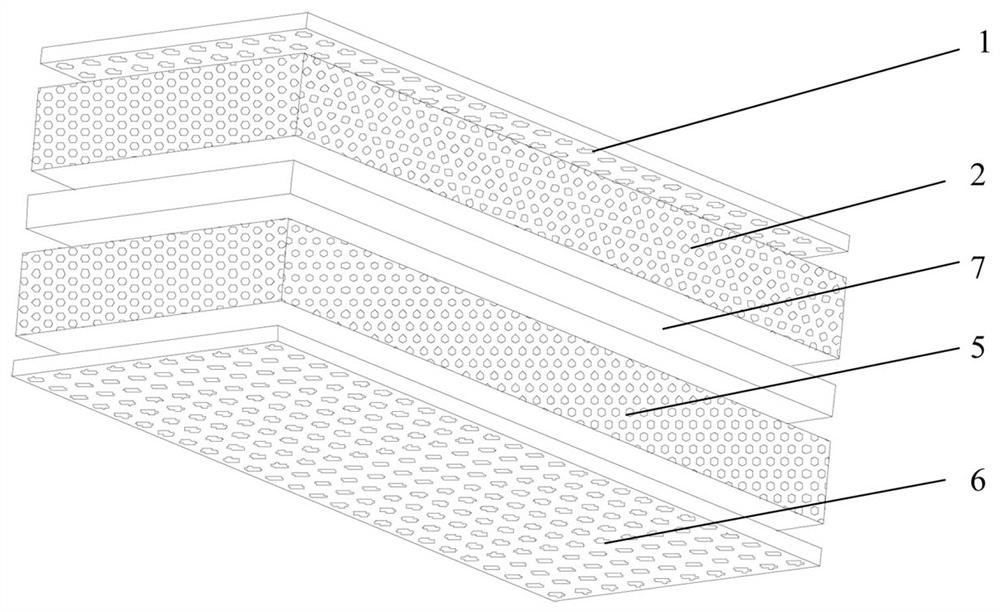

[0048] as attached figure 1 , 2 , 4, the present invention includes an upper V-shaped portion with an upward opening, a middle upright portion and a lower V-shaped portion with an opening downward, and the upper V-shaped portion, the middle upright portion and the lower V-shaped portion with an opening downward can be divided into There are two left and right parts, and the upper V-shaped part and the lower V-shaped part have the same structure and material. The left sides of the upper and lower vees and the left side of the middle upright face one transformer noise source, and the right sides of the upper and lower vees and the right side of the middle upright face the other transformer noise source.

[0049] The left side plate of the upper V-shaped part includes the front orifice plate 1, the front sound-absorbing layer 2 and the front thin steel plate 3 arranged in sequence from left to right, and the right side plate of the upper V-shaped part includes the rear plate ar...

Embodiment 2

[0057] The structure of this embodiment is consistent with that of Embodiment 1, and on the basis of Embodiment 1, a process connector 4 for connecting the upper V-shaped part, the middle upright part and the lower V-shaped part is added.

[0058] This embodiment includes all the technical features of Embodiment 1, that is, as attached figure 1 As shown, the present invention includes an upper V-shaped portion with an upward opening, a middle upright portion, and a lower V-shaped portion with an opening downward. The two parts, the upper V-shaped part and the lower V-shaped part have the same structure and material. The left sides of the upper and lower vees and the left side of the middle upright face one transformer noise source, and the right sides of the upper and lower vees and the right side of the middle upright face the other transformer noise source.

[0059] The left side plate of the upper V-shaped part includes the front orifice plate 1, the front sound-absorbing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com