Master control switch for water turbine speed regulator, water turbine speed regulator and water turbine

It is a technology of master control and control switch. It is used in machines/engines, mechanical equipment, hydropower and other directions. It can solve the problems of a lot of oil pollution and impurities that are easy to touch the photoelectric switch by mistake, and the real-time position of the blade cannot be accurately obtained. Avoid false touch effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

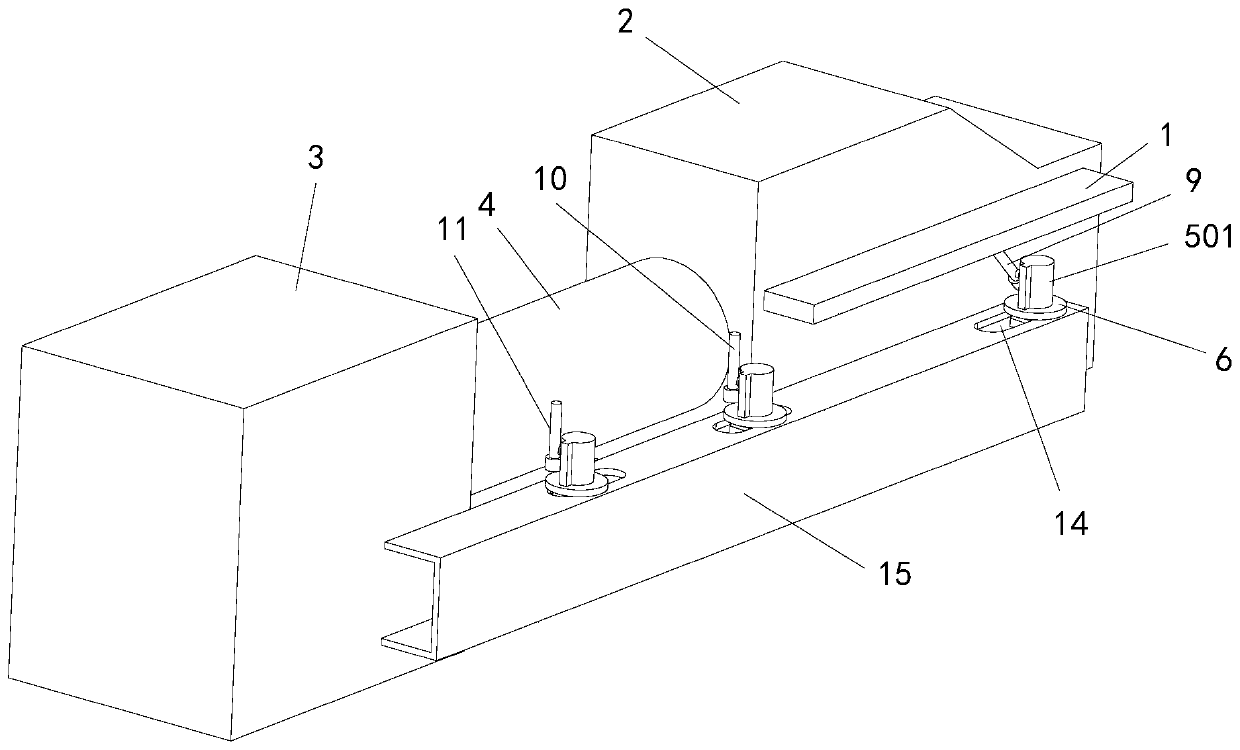

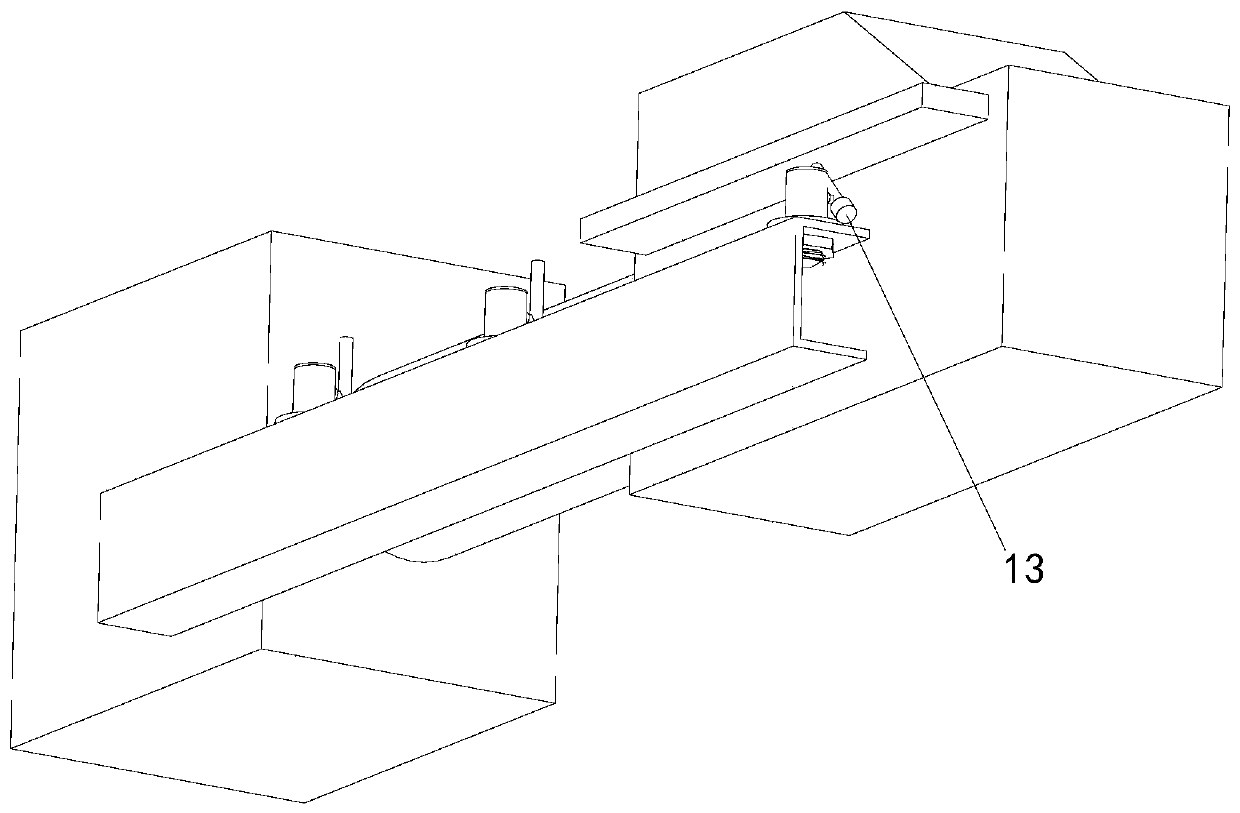

[0045] The invention provides a master control switch for a hydraulic turbine governor, comprising a photoelectric switch and a contact plate 1 connected to a control switch 2, the control switch 2 is moved by the action of a hydraulic cylinder 3, and the hydraulic cylinder 3 The push rod 4 is connected to the control switch 2.

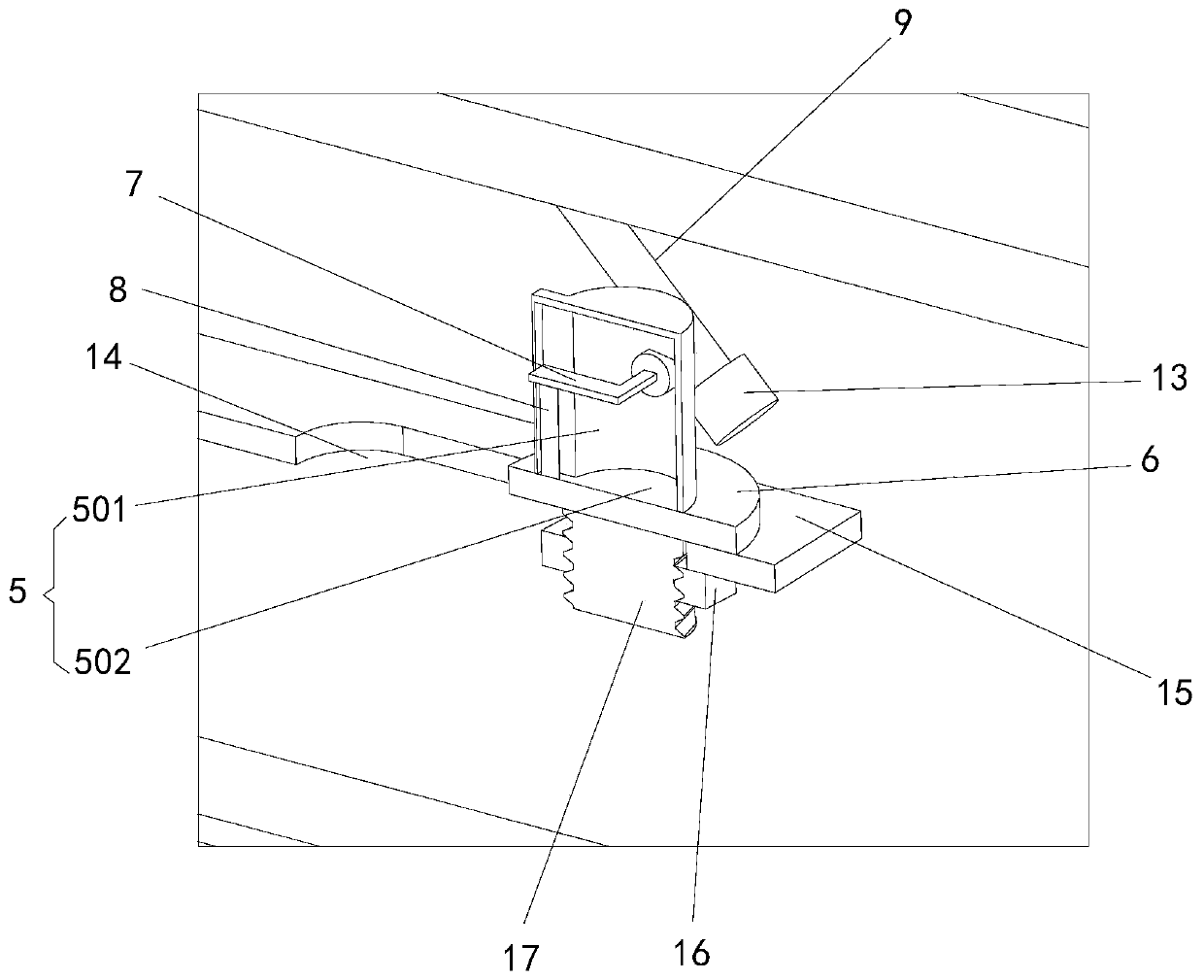

[0046]The outer cover of the photoelectric switch is provided with a sealed protective shell 5, and also includes a trigger mechanism for triggering the photoelectric switch;

[0047] The trigger mechanism includes a reflector, a rotating shaft and a contact rod; wherein,

[0048] The rotating shaft is rotatably connected to the protective shell 5, the reflector and the contact rod are respectively connected to the two ends of the rotating shaft, and the reflective plate and the contact rod are respectively located inside and outside of the protective shell 5; the reflector and the photoelectric The position of the switch corresponds; the position of...

Embodiment 2

[0075] A water turbine governor provided by the present invention includes the master control switch for the water turbine governor in Embodiment 1 above.

[0076] The turbine governor provided by the present invention, when in use, when the contact plate 1 moves with the control switch 2, the contact plate 1 can be in contact with the contact end of the contact rod to push the contact rod to rotate, and the contact rod drives the rotating shaft to rotate , the rotating shaft further drives the reflector to rotate, and the reflector can rotate with the rotation of the contact rod to the position where the photoelectric switch can be triggered. When the photoelectric switch is triggered, the inclination angle of the blade can be obtained according to the position of the triggered photoelectric switch; during use , because the outer cover of the photoelectric switch is provided with a sealed protective shell 5, through the protective shell 5, impurities such as oil and dust can b...

Embodiment 3

[0079] A water turbine provided by the present invention includes the master control switch for the water turbine governor in the first embodiment above.

[0080] The water turbine provided by the present invention, when in use, when the contact plate 1 moves with the control switch 2, the contact plate 1 can be in contact with the contact end of the contact rod to push the contact rod to rotate, and the contact rod drives the rotating shaft to rotate, and the rotating shaft then Drive the reflector to rotate, and the reflector can rotate with the rotation of the contact rod to the position where the photoelectric switch can be triggered. When the photoelectric switch is triggered, the inclination angle of the blade can be obtained according to the position of the triggered photoelectric switch; during use, due to the photoelectric switch The outer cover of the switch is provided with a sealed protective shell 5, through which impurities such as oil and dust can be isolated on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com