Automatic placing method and automatic placing device for protective sheet before storage battery capping

A technology of protection sheet and front protection, applied in the direction of lead-acid battery, lead-acid battery construction, assembling battery machine, etc., can solve the problems of low degree of automation and low quality, and achieve the effect of simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

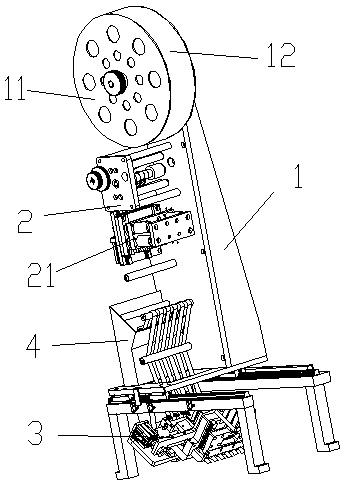

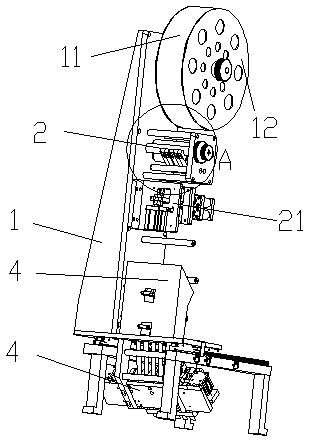

[0037] Such as figure 1 and figure 2 As shown, an automatic placement device for the protective sheet before the battery cover includes a frame 1, and other components are all arranged on the frame 1 in order from top to bottom. The uppermost end of the frame 1 is provided with a rotatable reel 11 on which a purchased roll-shaped protective sheet 12 is placed. Pulled by the lower structure, the reel 11 rotates to release the protective sheet 12 . In this embodiment, in order to clearly show the structure of the automatic placement device, some parts of the protective sheet 12 are not shown in the figure.

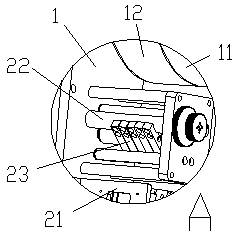

[0038] Such as image 3 and Figure 4 As shown, the strip cutting mechanism 2 is below the reel 11, and the strip cutting mechanism 2 includes a pressing roller 22 and a strip cutting seat 23 arranged on the frame 2. In the present embodiment, the pressing roller 22 is arranged above the strip cutting seat 23, The protective sheet 12 that stretches out from the reel 11 pa...

Embodiment 2

[0047] The structure and method of this embodiment are basically the same as in Embodiment 1, the difference is that the placement hole of the protective sheet 12 is the hole surrounded by the tabs of the battery box, and the battery box needs to be turned over during the capping process, so the protective sheet 12 must be Fasten between the tabs to prevent the battery box from falling out of the hole after being flipped over. At this time, an ejection assembly needs to be set at the edge of the movable plate 36, such as Figure 11 As shown, a plurality of ejector rods 61 are arranged below the ejector assembly, and a power unit 662 is arranged above. In this embodiment, the power part six 62 is a cylinder, and the size of the protective sheet 12 is slightly larger than the size of the hole between the tabs. After the slicer 361 cuts the protective sheet 12, the protective sheet 12 falls on the tab. The power part six 62 Push the ejector assembly 6 to move downward, and the e...

Embodiment 3

[0050] In this example, if Figure 8 As shown, there is an intermediate plate 5 at the outlet of the channel, such as Figure 9 and Figure 10 As shown, the middle plate 5 is provided with a through hole 51, the movable plate 36 is arranged on the top of the middle plate 5, and the slicing knife 361 is positioned at the edge of the through hole 51 near the channel, and the middle plate 5 provides the counteraction of the slicing knife 361 cutting the protective sheet 12. force. An ejector assembly 6 is also arranged above the middle plate 5 , and its ejector rod 61 is matched with the through hole 51 one by one. The placement hole in this embodiment can be the hole in the middle cover or the hole surrounded by the tabs in the battery box. The middle cover or the battery box is transported to the bottom of the middle plate by the transport mechanism. The through holes 51 match the placement holes one by one. The through hole 51 is slightly larger than the placement hole, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com