Cutting tool with adjustment mechanism

A cutting tool and adjusting mechanism technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing, etc., can solve the problems of inaccurate characteristics and limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

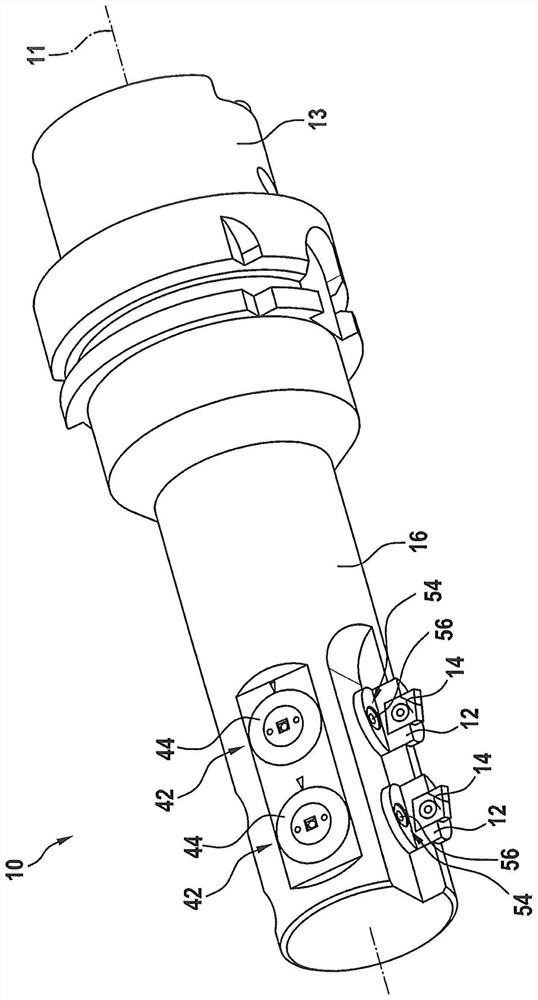

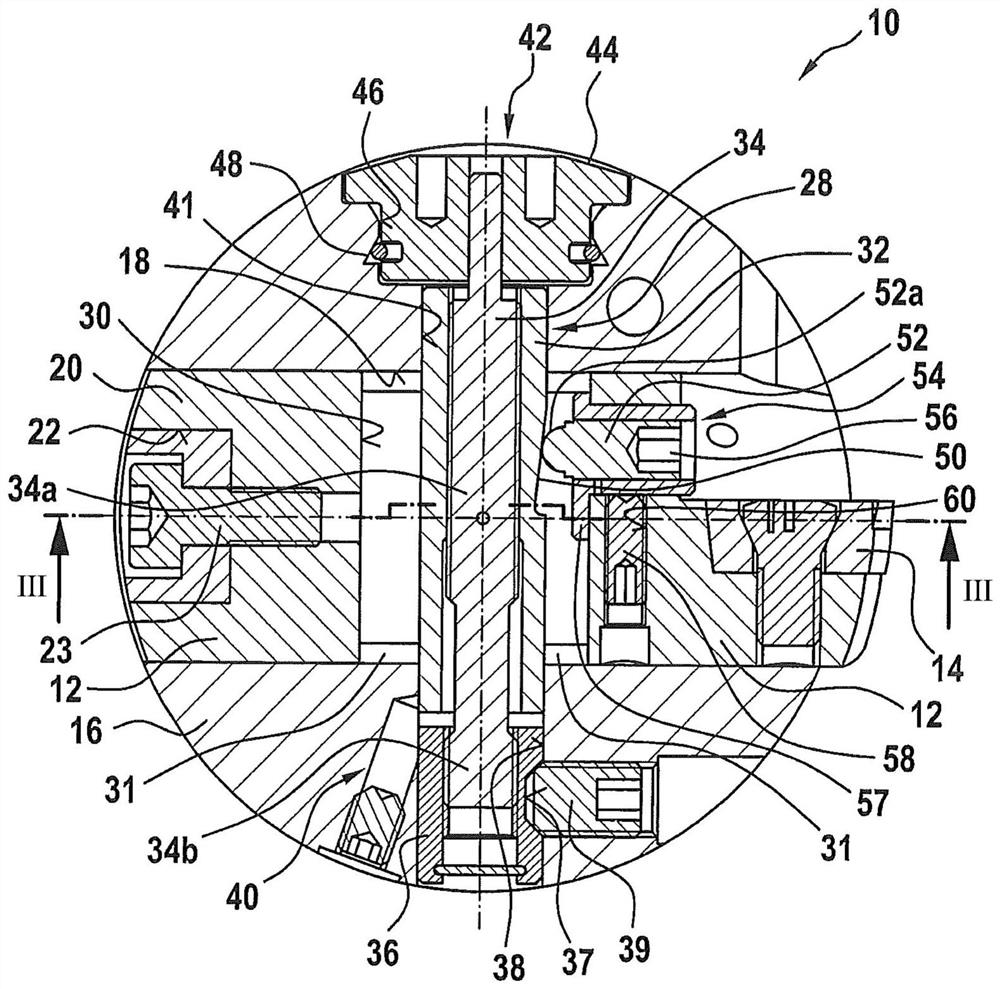

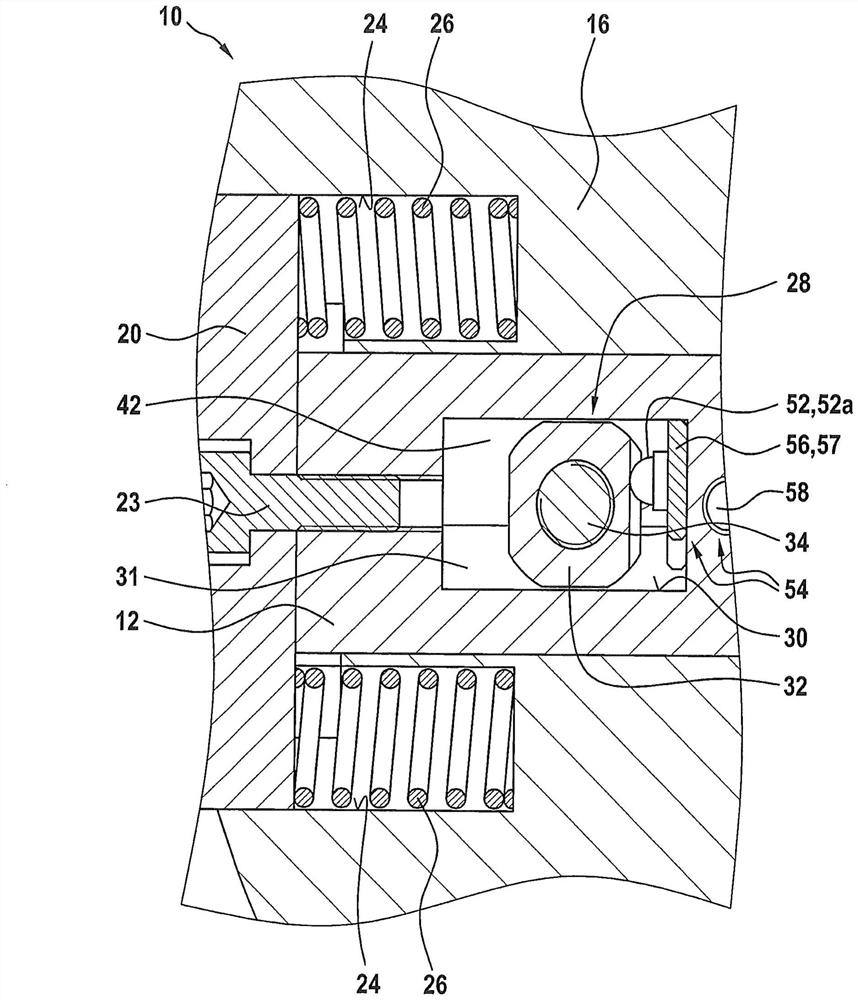

[0034] exist Figure 1 to Figure 3 A cutting tool 10 according to a first embodiment of the invention is shown in cross-section and longitudinal section and in side view. The cutting tool 10 has at least one cutting edge carrier 12 with a cutting element 14 . The cutting element 14 may consist of a blade, in particular an indexable blade. As an alternative, the cutting edge carrier 12 may eg carry cutting inserts, cutting strips or the like as cutting elements instead of blades. The cutting element 14 anyway has at least one geometrically defined cutting edge for chip-removing machining of the associated machining location, in particular a layer location. The cutting tool 10 is preferably equipped with a not shown cooling or coolant supply.

[0035] For the machining of multiple bearing points for bearing shells (not shown), the cutting tool 10 preferably has a plurality of cutting edge carriers 12 with cutting elements 14 which extend in the axial direction or longitudinal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com