Machine for producing or processing fibrous material

A machine, fiber technology, applied in the field of machines for manufacturing or processing fibers, which can solve problems such as large component size, and achieve the effect of easy installation and maintainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

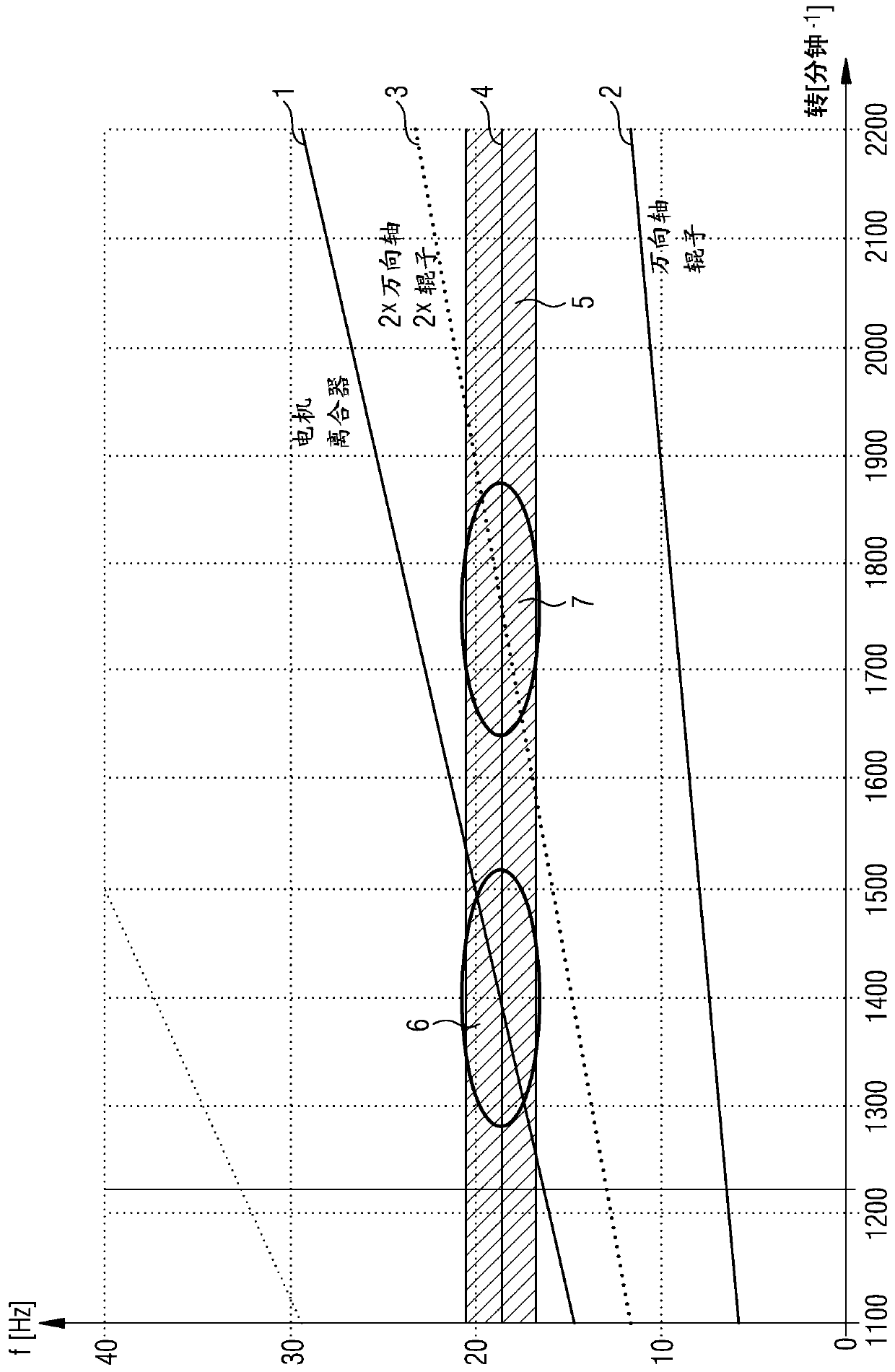

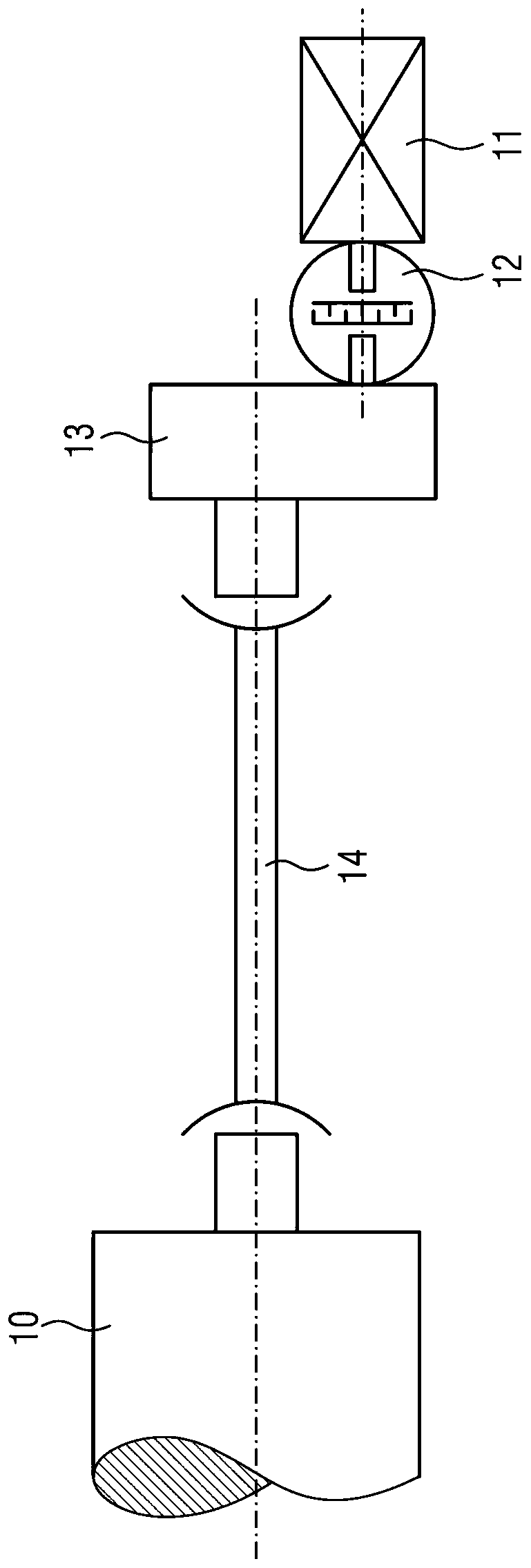

[0025] In the Campbell plot ( figure 1 ), with respect to the rotational speed of the components as the ordinate, on the abscissa the natural frequencies of the different driven and driven components of a machine for producing and / or processing fibrous webs according to the prior art are plotted .

[0026] figure 1 It is shown how, in machines according to the prior art, depending on the operating drive or driven drive train, resonances can occur, ie vibrations are induced in the range of the natural frequency of the drive train, the vibrations are only slightly attenuated and thus Amplified by additional energy delivery. The frequency is shown by lines 1, 2 and 3 as a function of the double rotational speed of the unit consisting of the motor and clutch and the unit consisting of the cardan shaft and roller Vibration or cycling during operation at different rotational speeds.

[0027] Use 4 to represent the fundamental torsional natural frequency of the drive train, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com