Liquid optical phase modulator with configurable adjusting range and precision

A technology of adjustment range and phase modulator, applied in the field of optical phase modulation, can solve the problems of small phase modulation range, low precision, complex structure, etc., and achieve the effect of configurable adjustment range and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

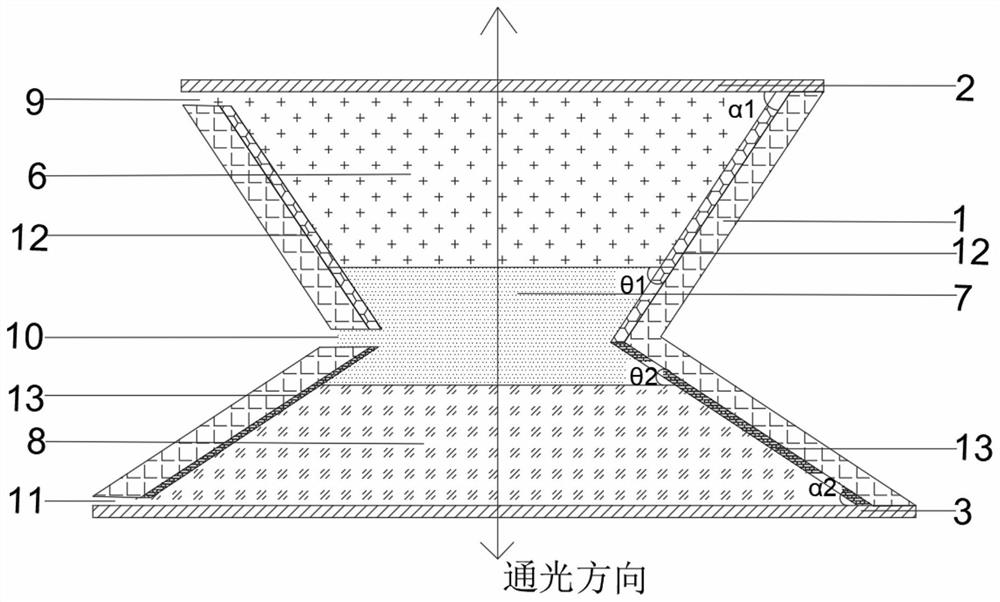

[0054] like Figure 4-5 As shown, the present invention is a liquid optical phase modulator with configurable adjustment range and precision. The liquid optical phase modulator includes a solid inner core cavity 1, a transparent upper cover sheet 2 and a transparent lower cover sheet 3. The The transparent upper cover sheet 2 and the transparent lower cover sheet 3 are arranged in parallel, and the upper and lower transparent cover sheets are made of transparent acrylic glass sheets. The body can be a glass core cavity made of quartz sand, limestone, feldspar, soda ash, boric acid and other glass raw materials through high temperature. The splicing of the upper and lower circular cones is defined as the splicing interface. The side wall of the circular table is made separately with the splicing interface as the boundary. After the upper part is fabricated, the inner wall of the solid core cavity is coated with a Teflon hydrophobic layer 12 , and the included angle between th...

Embodiment 2

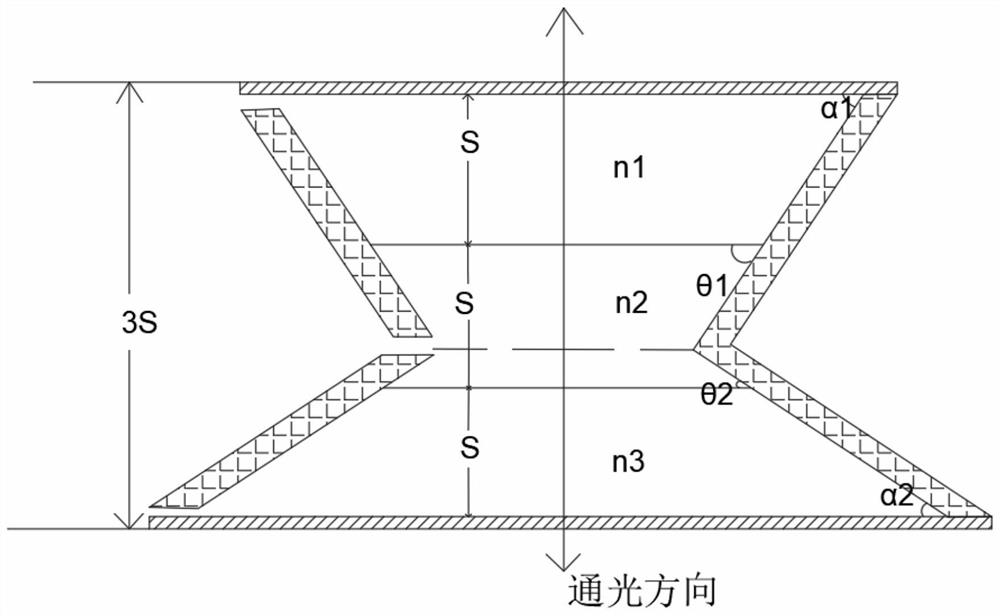

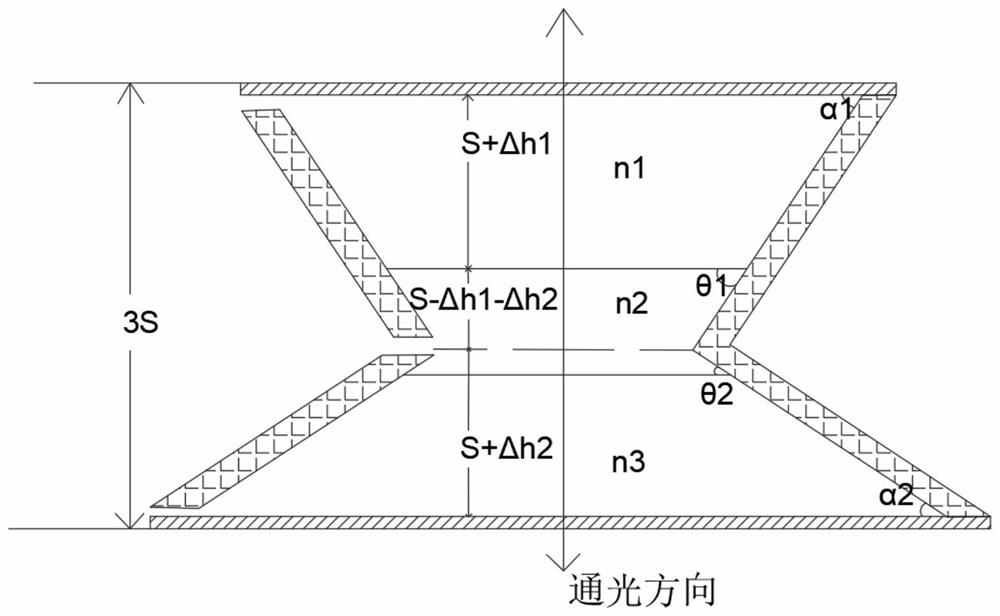

[0056] like Figure 6-7 As shown, the present invention is a liquid optical phase modulator with configurable adjustment range and precision. The liquid optical phase modulator includes a solid inner core cavity 1, a transparent upper cover sheet 2 and a transparent lower cover sheet 3. The The transparent upper cover sheet 2 and the transparent lower cover sheet 3 are arranged in parallel, and the solid inner core cavity is formed by splicing two prism side walls up and down by splicing isosceles trapezoid surfaces, such as Image 6 As shown, the solid inner core cavity is made of PLA material through 3D printing. First, the drawings are made with drawing software such as CAD, and then the finished product is printed with a 3D printer. The angle α between the isosceles trapezoid side wall and the top surface of the side wall of the upper prism formed by splicing isosceles trapezoid surfaces 1 Equal to the contact angle θ of liquid 1 - liquid 2 - frustum side wall 1 1 , to e...

Embodiment 3

[0058] like Figure 8-9 As shown, the present invention is a liquid optical phase modulator with configurable adjustment range and precision. The liquid optical phase modulator includes a solid inner core cavity 1, a transparent upper cover sheet 2 and a transparent lower cover sheet 3. The The transparent upper cover sheet 2 and the transparent lower cover sheet 3 are arranged in parallel, and the solid inner core cavity 1 is formed by splicing up and down the side walls of the prism which are spliced by the side walls of a circular truncated table and an isosceles trapezoid surface, such as Figure 8 As shown, the solid inner core cavity 1 is made of the upper and lower parts by 3D printing PLA material, and the two parts are tightly adhered together by Kesemi 540AB glue. The inner wall of the solid inner core cavity 1 is coated with a polyolefin hydrophobic layer to improve the contact angle by hydrophobic modification. The angle α between the side wall of the truncated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com