Ultrahigh-speed processing platform for high-power laser device

A high-power laser, processing platform technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of fast crystal growth technology not working well, expensive, and low moving speed, and achieves occupational occupation. The effect of small space, low cost and simple production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

[0019] The invention proposes a set of moving platform suitable for high-power laser processing. When the speed of the moving platform is too small to reach the speed required by the experiment, the experimental instrument can be used as a set.

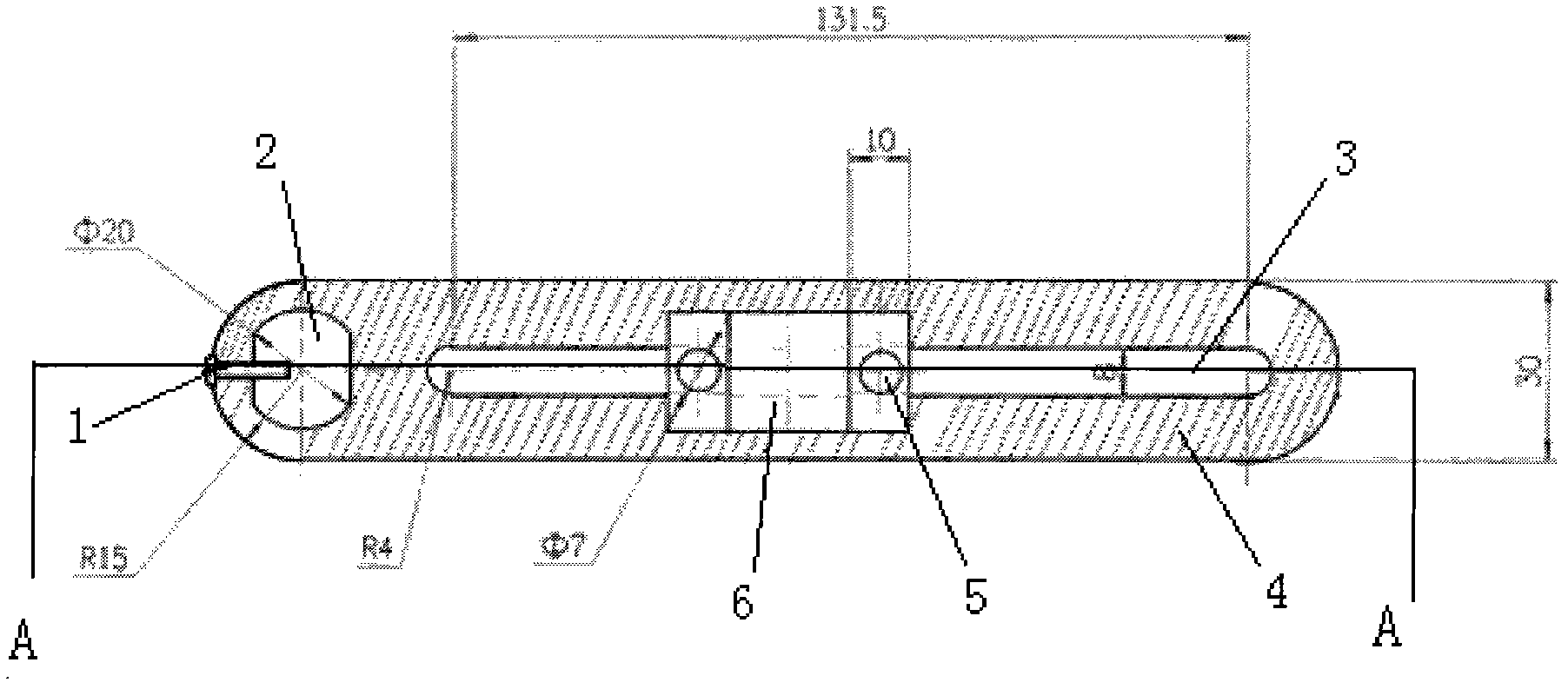

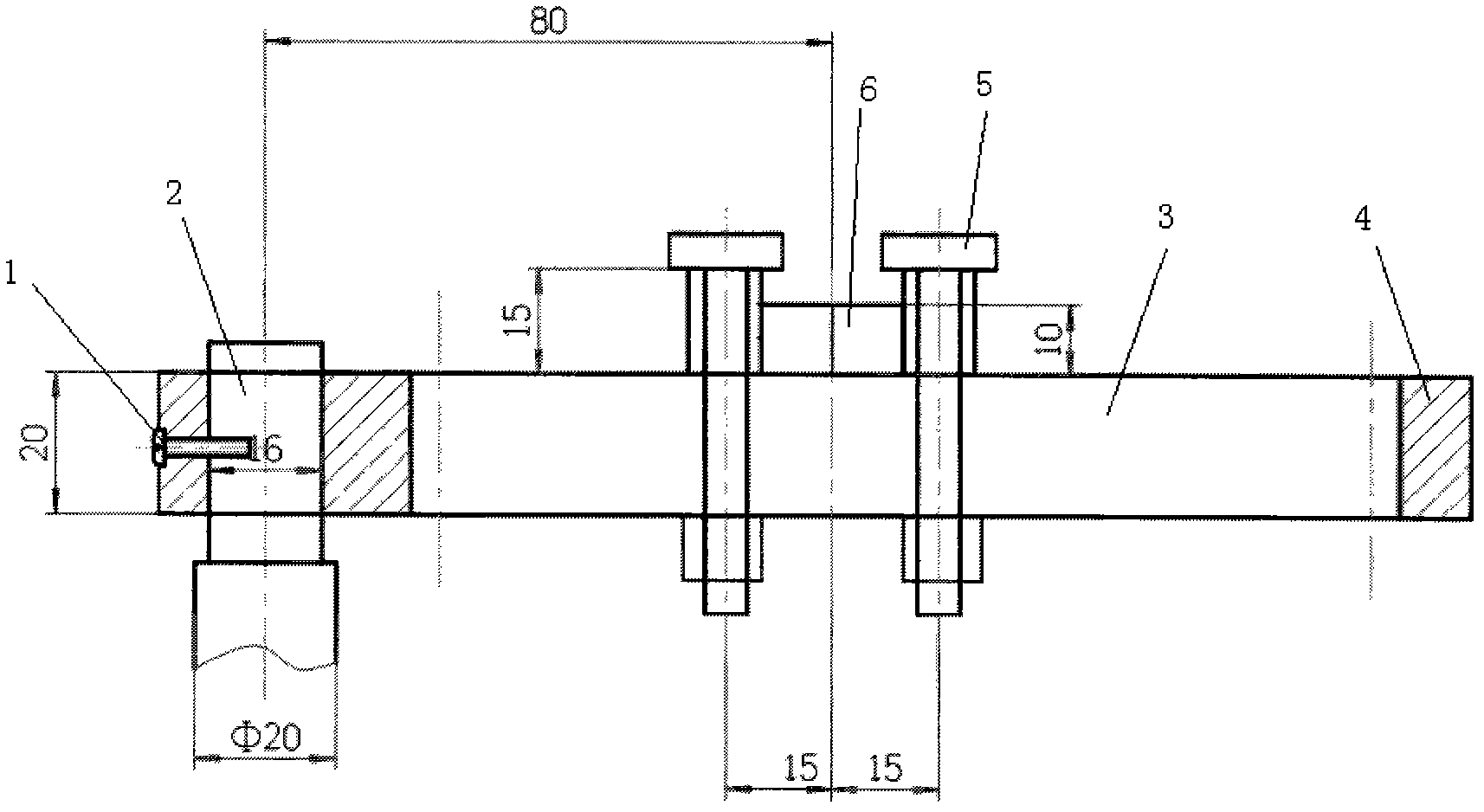

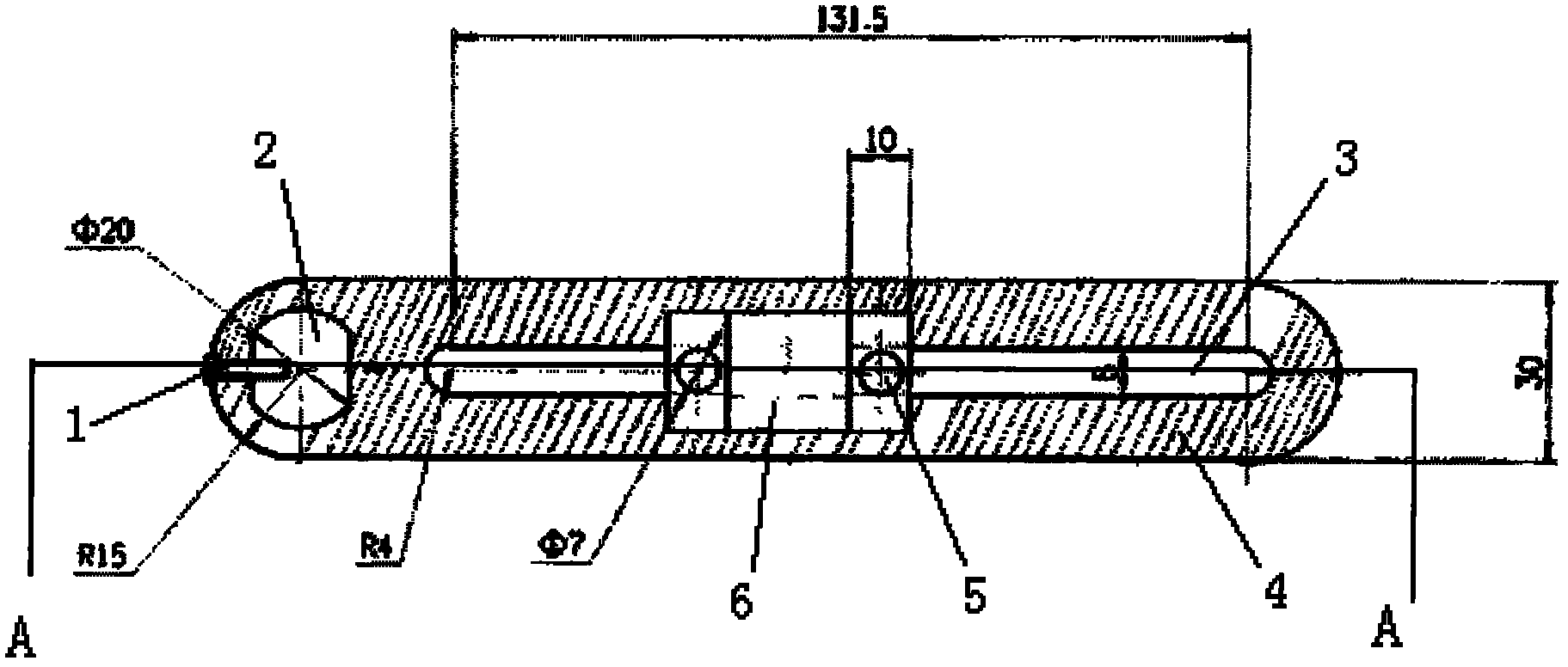

[0020] In this embodiment, a rotating arm 4 and a processing platform 6 are included; the processing platform 6 and two fixing screws 5 are made of superalloy material higher than 600° C., and the rotating arm 4 is made of soft aluminum material.

[0021] The pivoting arm 4 is in the shape of a long axis, with a width of 30mm and a height of 20mm, and the two ends are designed as semicircular arcs; the length of the guide rail through hole 3 in the center of the pivoting arm 4 is 131.5mm, the width is 7mm, and the two ends are of radius 3.5mm. Semi-arc design; the shaft hole 2 where one end of the rotating arm 4 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com