Active vibration noise control mechanism and method for beam structure

A technology of vibration noise and beam structure, applied in the field of mechanical vibration, to achieve the effect of adjusting range, suppressing noise radiation, and wide-band adjusting range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

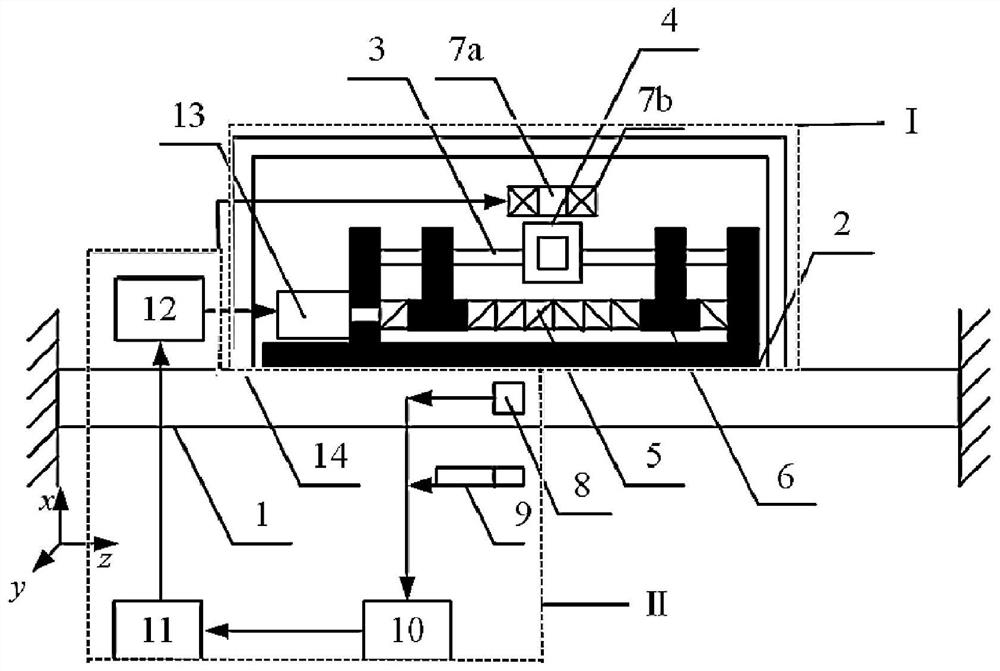

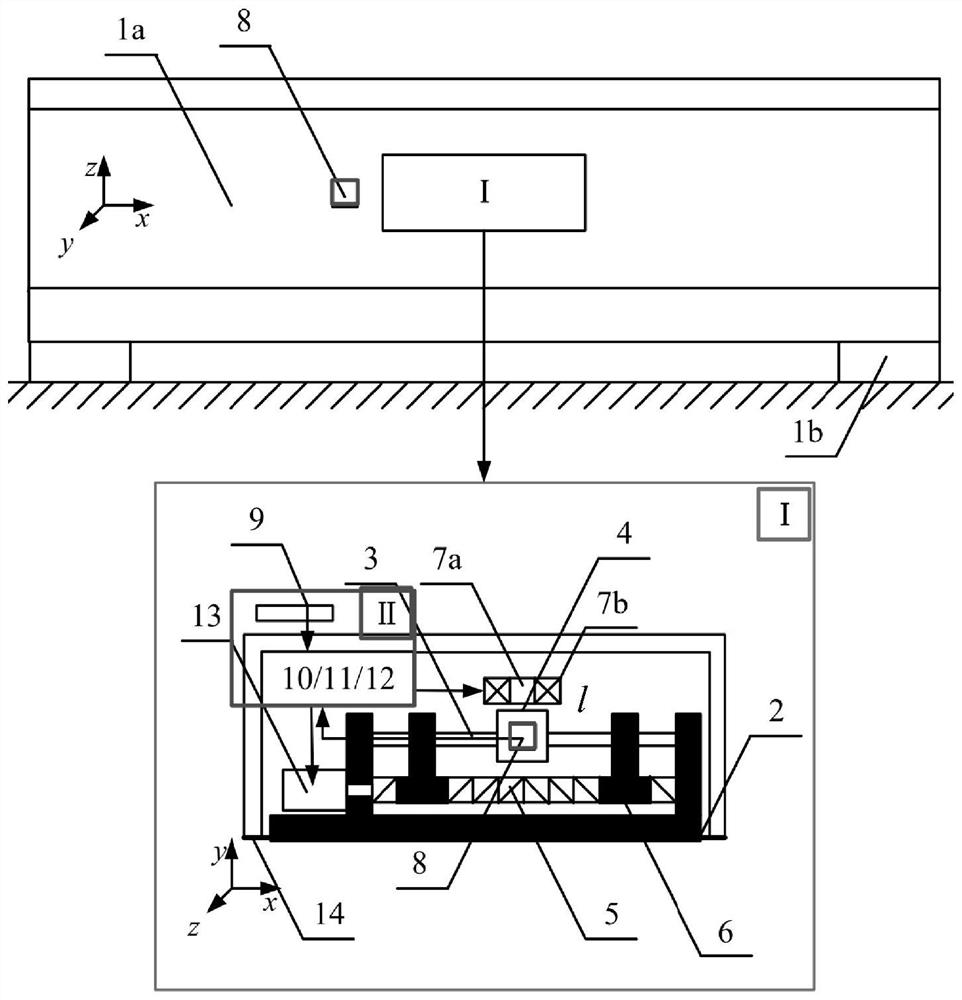

[0033] Such as figure 1 As shown, this embodiment relates to an active vibration and noise control system for realizing the above method, including: a two-way electromagnetic semi-active dynamic vibration absorber 1, which is connected to it for tracking the changes of two frequencies of beam structure vibration and noise respectively. Data acquisition system and algorithm and control system.

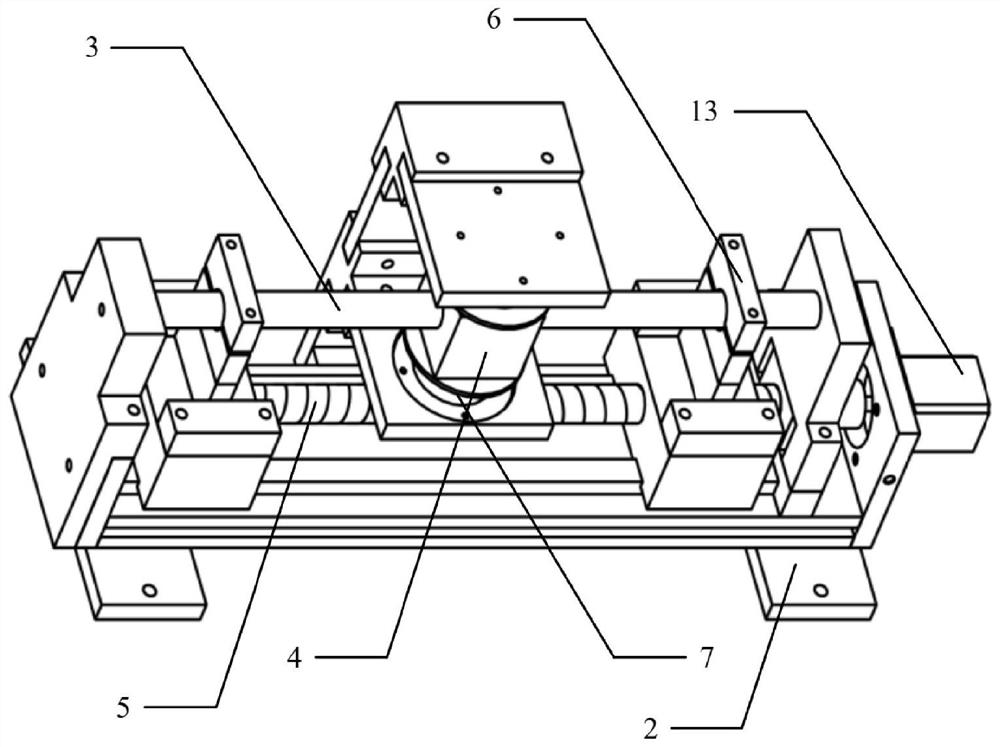

[0034] Described two-way electromagnetic semi-active dynamic vibration absorber 1 comprises: base 2 and the beam structure 3 that is arranged on it and leading screw 5, wherein: beam structure 3 is provided with concentrated mass body 4, and beam structure 3 is supported by moving The seat 6 is arranged on the lead screw 5, and the movable support seats 6 on both sides are adjusted by the lead screw 5 to realize variable rigidity. The dynamic vibration absorber chooses the first stiffness adjustment method, fixes the relative positional relationship between the concentrated mass body 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com