A cross wedge rolling mill for forming tiny shafts

A technology for cross wedge rolling mills and shafts, which is applied in the field of cross wedge rolling mills, can solve the problems that the production requirements of small shaft parts cannot be met, the efficiency and accuracy cannot meet the market demand, and the diameter of small shaft parts is small, etc., and the utilization of materials can be achieved. High rate, low environmental pollution, moderately guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

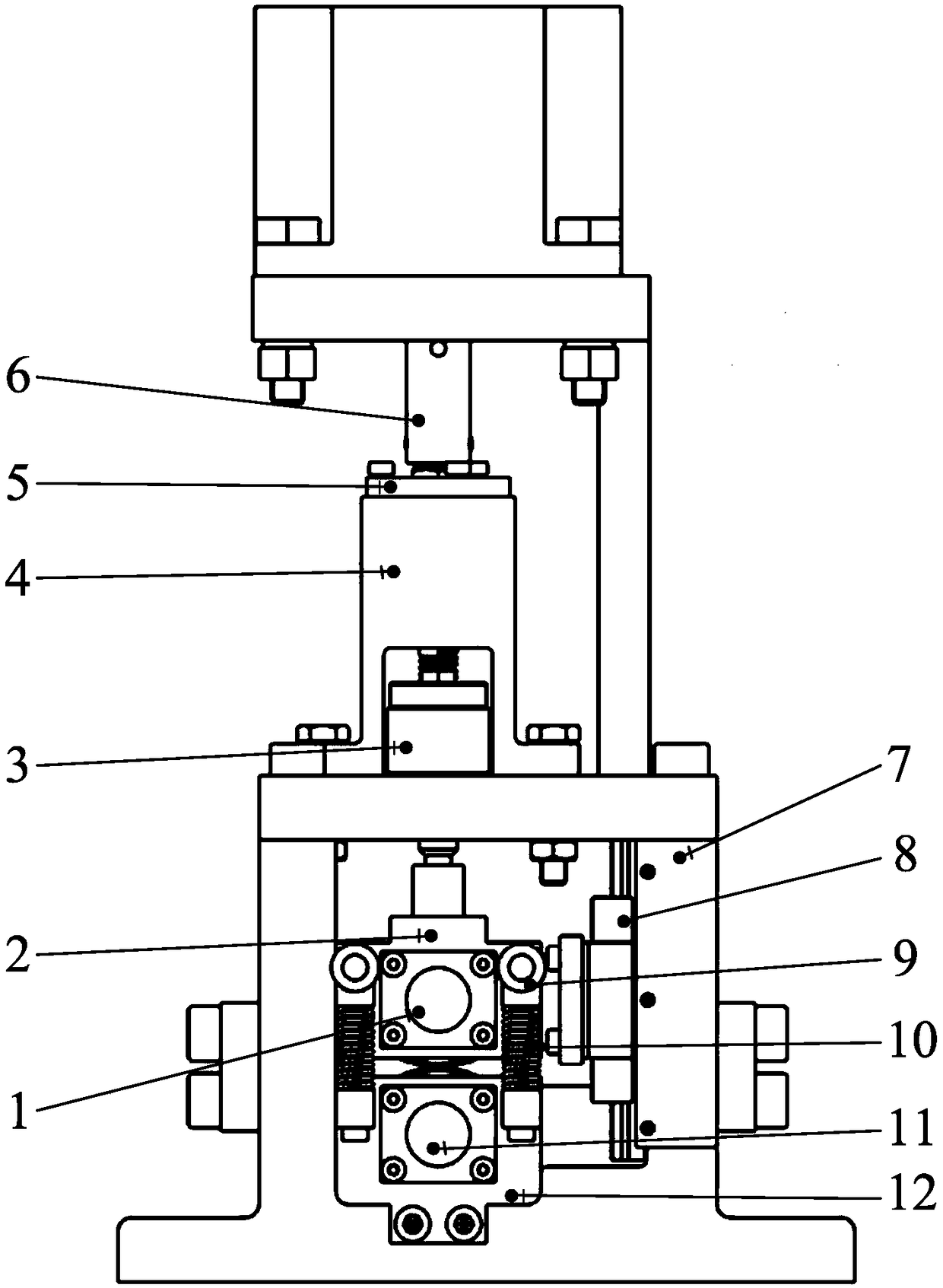

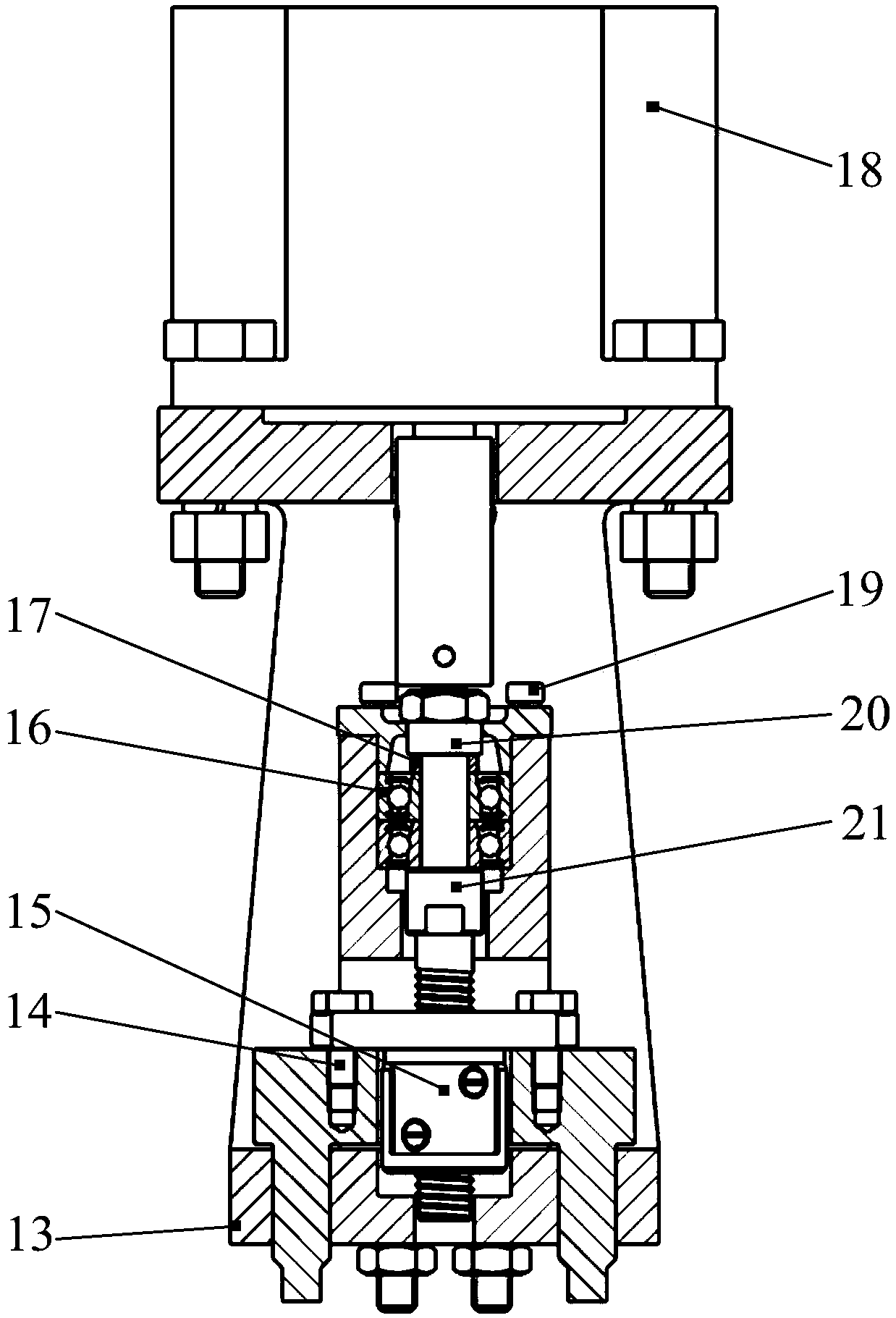

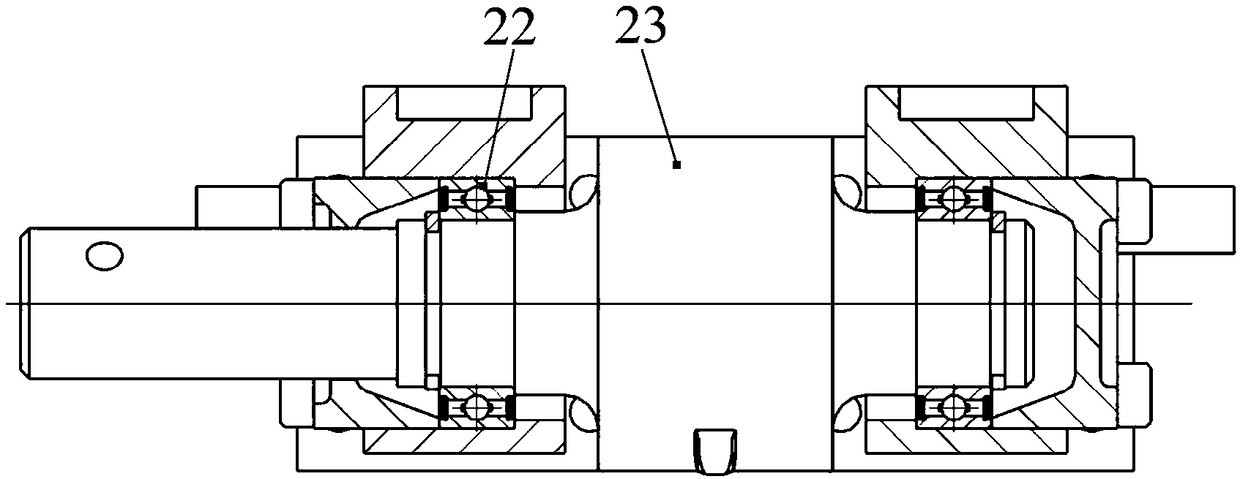

[0014] see Figure 1~5 , a cross wedge rolling mill for forming tiny shafts provided by an embodiment of the present invention, comprising: an upper bearing cover 1, an upper roll bearing seat 2, a pressing frame plate 3, a screw shaft end bearing seat 4, a screw Shaft end bearing cover 5, coupling 6, frame 7, rolling guide rail 8, lifting rod 9, coil spring 10, lower bearing cover 11, lower roll bearing seat 12, frame plate 13, screw 14, nut 15 , Angular contact ball bearing 16, spacer ring 17, stepping motor 18, screw 19, lock nut 20, screw rod 21, deep groove ball bearing 22, upper roller 23, lower roller 24. Wherein, upper and lower rolls 23,24 are installed in upper and lower roll chocks 2,12 through deep groove ball bearings 22, upper and lower roll chocks 2,12 are connected together by four lifting rods 9, and lifting rods 9 A coil spring 10 is set i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com