Device for labelling containers

A technology for labeling and equipment, which is applied in the field of equipment for labeling containers, and can solve the problems of expensive, time-consuming and difficult to set accurately.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

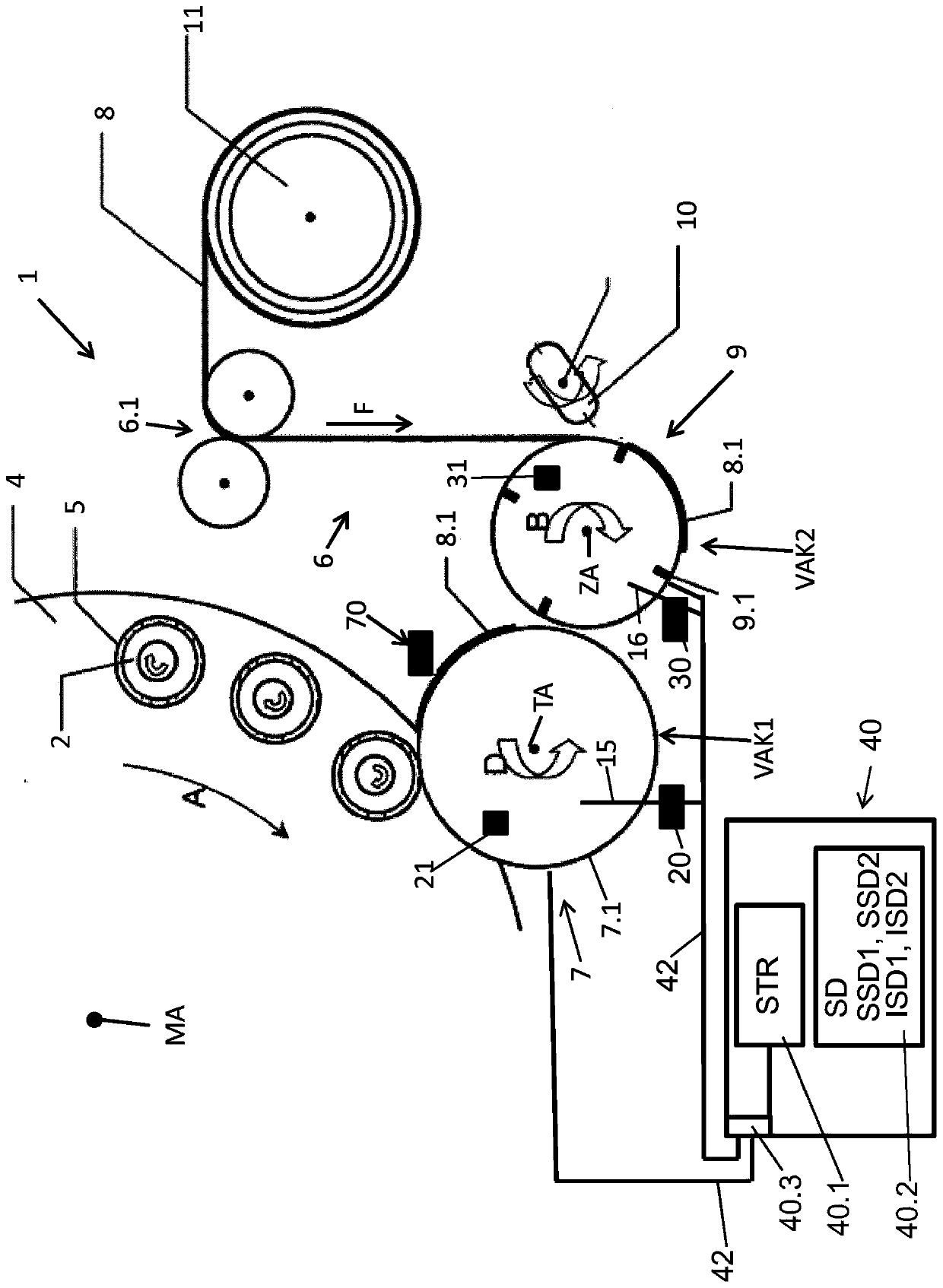

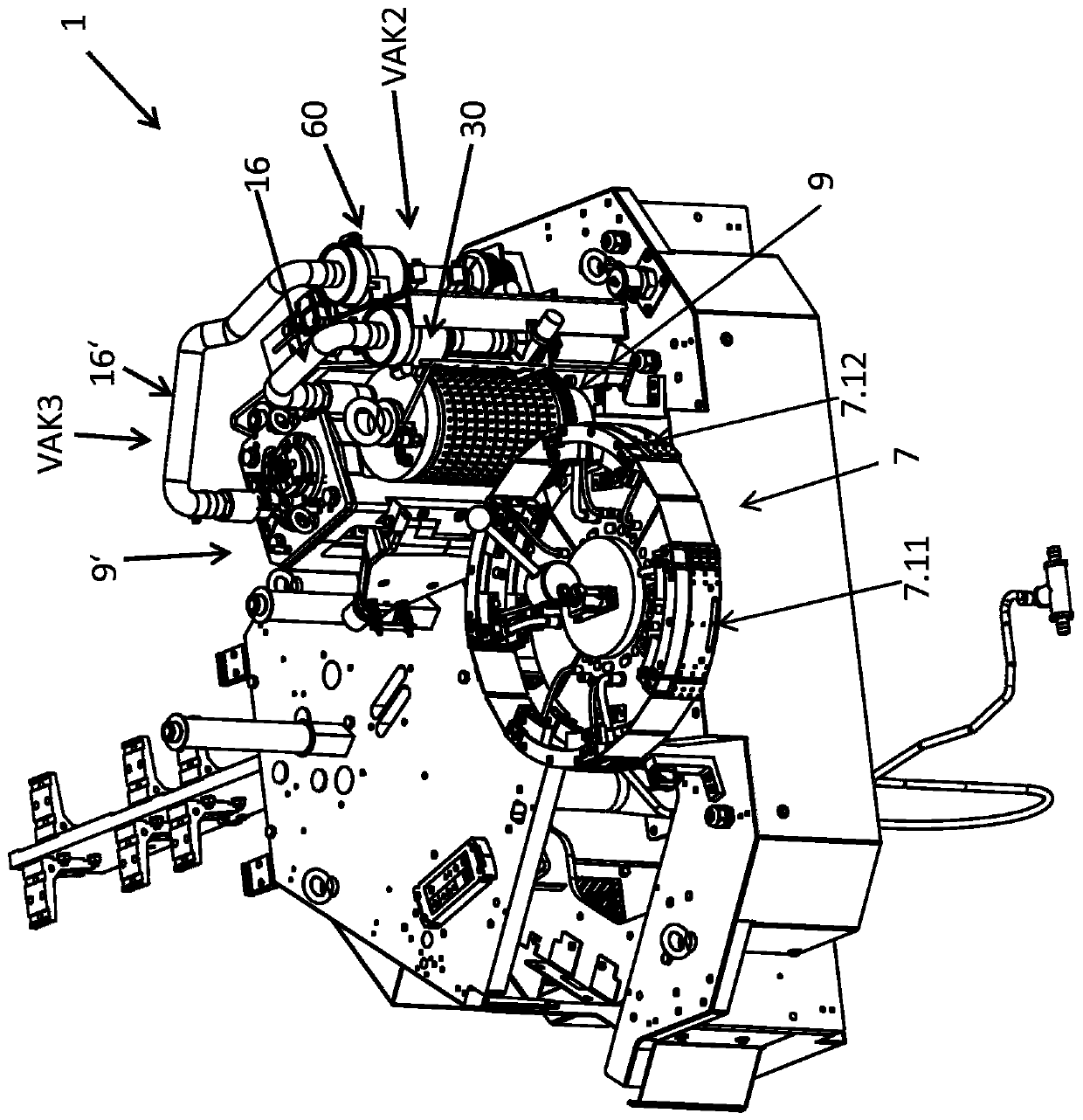

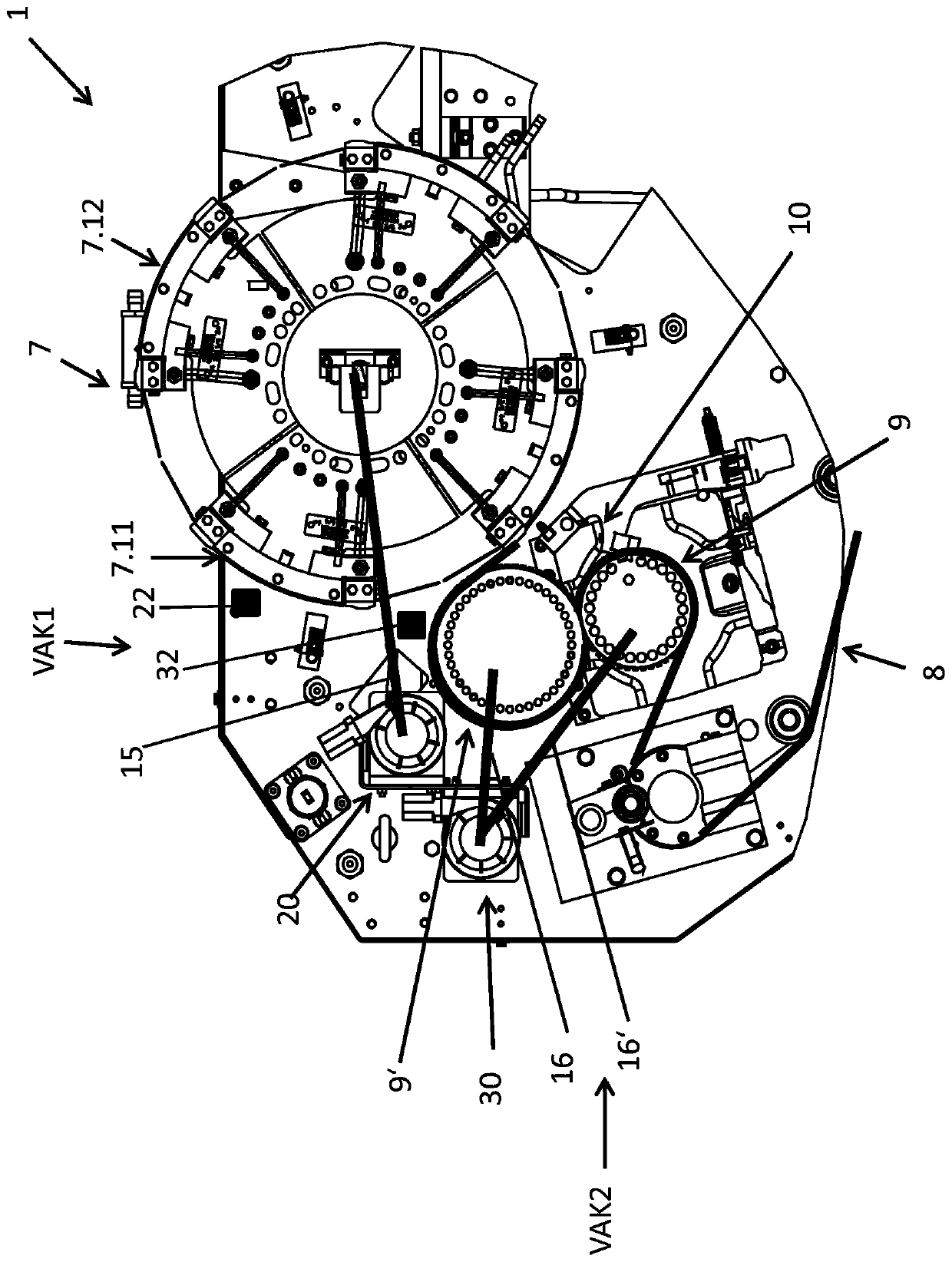

[0039] A device, designated collectively by 1 in the figures, is used for labeling containers 2 , in particular bottles, and is preferably designed as a rotary labeling machine.

[0040] Furthermore, the device 1 interacts in a manner known to those skilled in the art, inter alia, with a rotor 4 driven in rotation about the vertical machine axis MA in the direction of the arrow A (in clockwise direction), however, said rotor It is not an integral part of the device 1 and the rotor has a plurality of container holders 5 in the form of rotating disks on its circumference.

[0041] On the rotating disk 5 , during the labeling operation, the containers 2 are accordingly arranged upright (that is to say with their container vertical axes oriented parallel or substantially parallel to the machine axis MA in the vertical direction). Containers 2 to be labeled are fed to the rotor 4 at a container inlet (not shown) and leave the rotor at a container outlet (likewise not shown) after l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com