A kind of aluminosilicate glass and preparation method thereof

An aluminosilicate glass, fe2o3 technology, applied in the field of glass, can solve problems such as difficulty in clarifying glass liquid, and achieve the effects of simple clarification, good transmittance, and improved heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, embodiments of the present invention will be described in further detail.

[0030] 1. Aluminosilicate glass

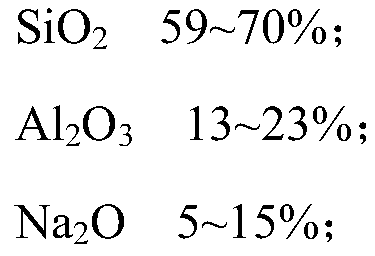

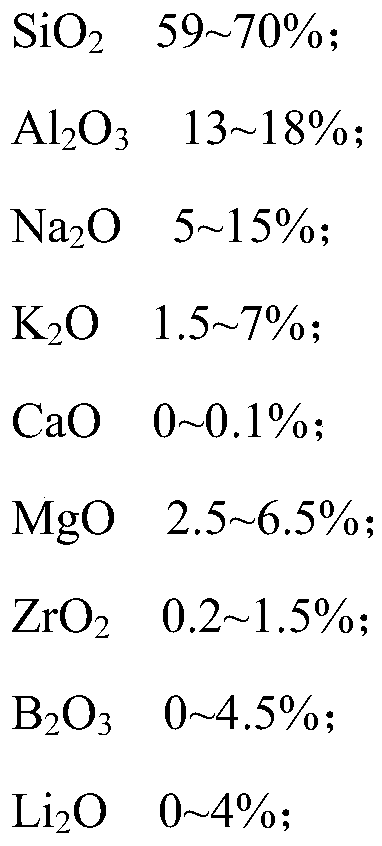

[0031] The aluminosilicate glass according to the embodiment of the present invention, based on oxides, by mass percentage, includes:

[0032]

[0033] At the same time, the aluminosilicate glass also includes 150ppm-550ppm Fe 2 o 3 , and Fe 2 o 3 When it is 150ppm~300ppm, the ratio Redox of ferric ion mass to all iron ion mass is 35~45%; Fe 2 o 3 When the concentration is 300ppm-550ppm, the ratio Redox of the mass of divalent iron ions to the mass of all iron ions is 25-35%.

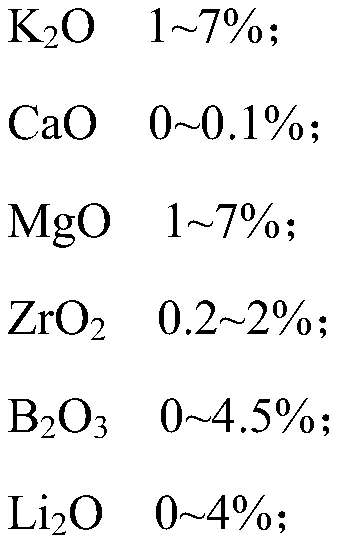

[0034] Preferably, the aluminosilicate glass, based on oxides, includes by mass percentage:

[0035]

[0036] At the same time, the aluminosilicate glass also includes 150ppm-550ppm Fe 2 o 3 , and Fe 2 o 3 When it is 150ppm~300ppm, the ratio Redox of ferric ion mass to all iron ion mass is 35~45%; Fe 2 o 3 When the concentration is 300ppm-550ppm, the ratio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com