Hydraulic lifting type hot riveting device

A technology of hydraulic lifting and hot riveting, which is applied in the field of rail passenger car production equipment, can solve problems such as poor applicability, difficulty in on-site maintenance, and limitation of riveting positions, and achieve low skill level requirements, reasonable structural design, and wide promotion value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0073] see Figure 1 to Figure 6 shown;

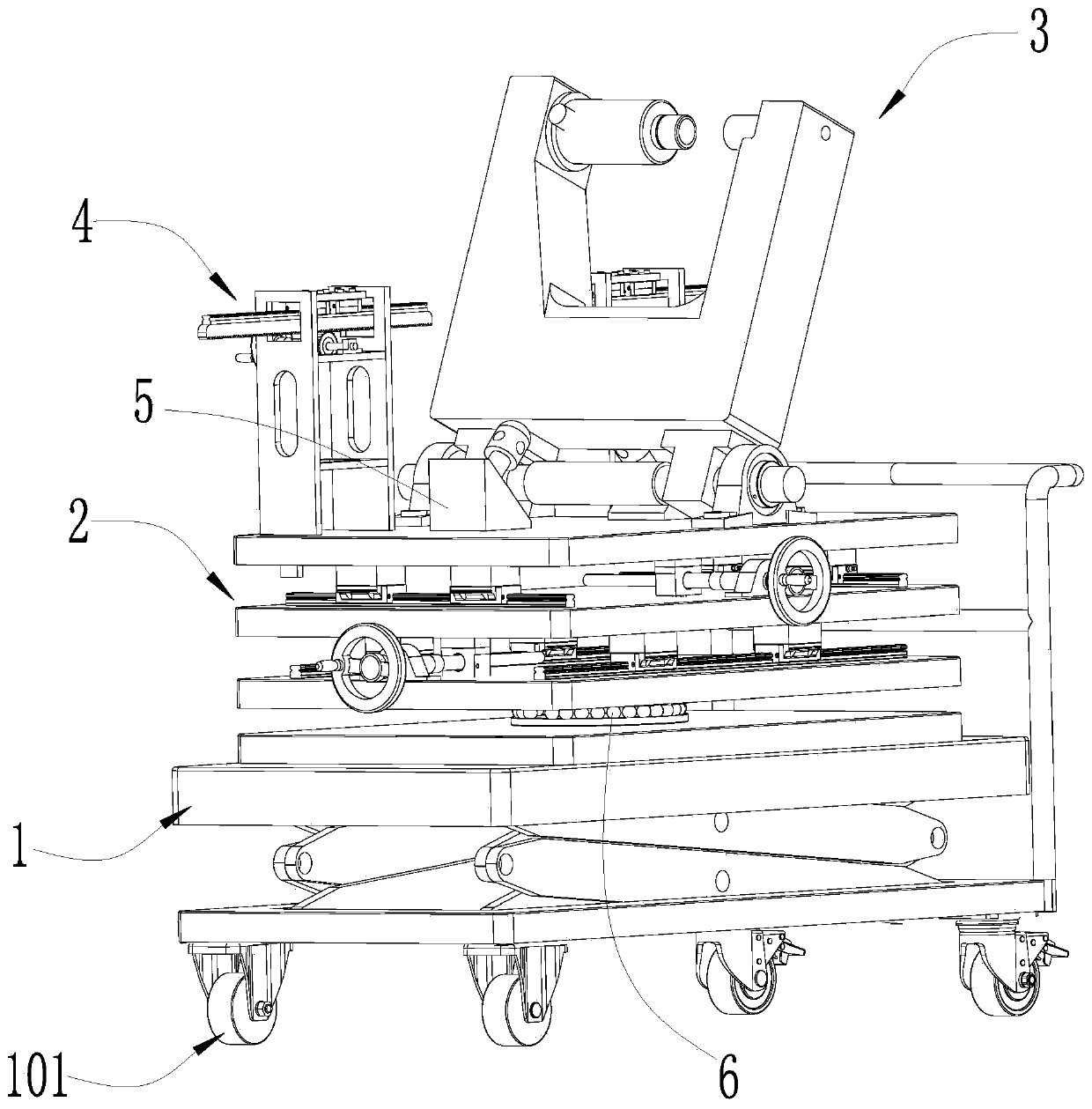

[0074] The hydraulic lifting type hot riveting device 12 of the present invention mainly includes:

[0075] Hydraulic lifting assembly 1, the lower part of hydraulic lifting assembly 1 is equipped with universal casters 101;

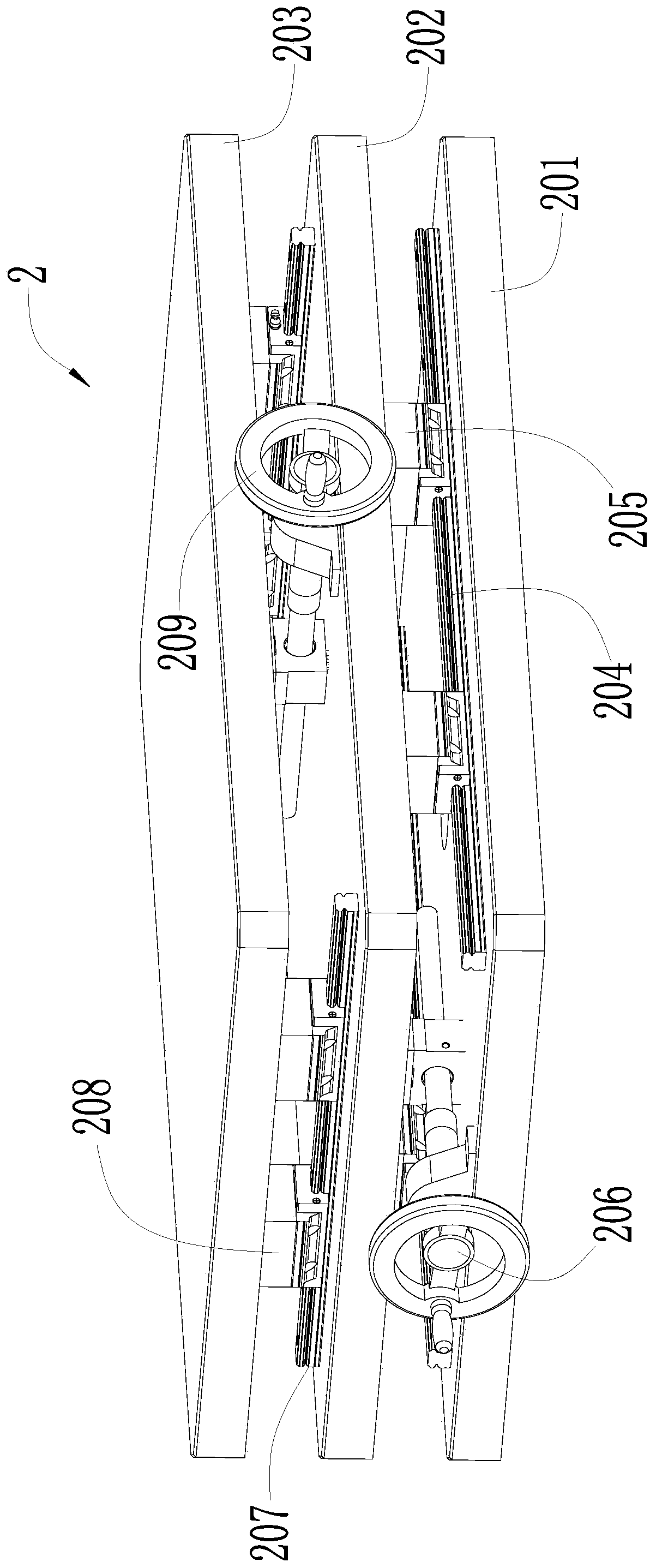

[0076] A horizontal position adjustment assembly 2 assembled on the upper part of the hydraulic lifting assembly 1; and

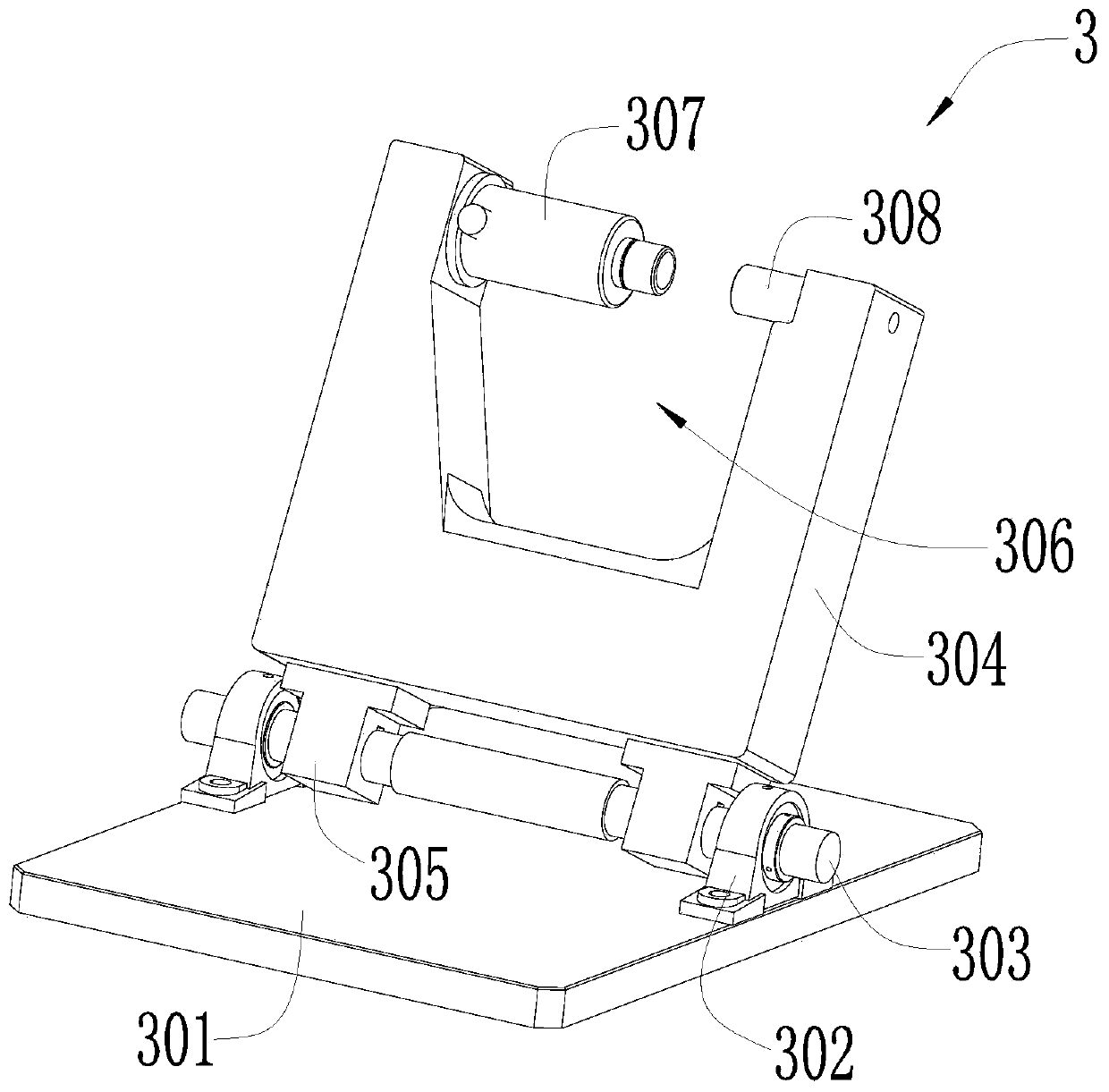

[0077] The rivet clamp installed on the top of the horizontal position adjustment assembly 2 forms 3;

[0078] The end of the rivet pliers component 3 away from the horizontal position adjustment component 2 is configured as the working end, and the rivet pliers component 3 acts on the heated riveting piece of the workpiece through the working end;

[0079] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com