Vanish mould for casting polystyrene foam

A technology of polystyrene foam and polystyrene foam, which is applied in the field of polystyrene foam casting lost foam, can solve the problems of inconvenient production, handling and operation, time-consuming and labor-intensive, etc., and achieve easy portability, transportation and operation, The effect of big economy and promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

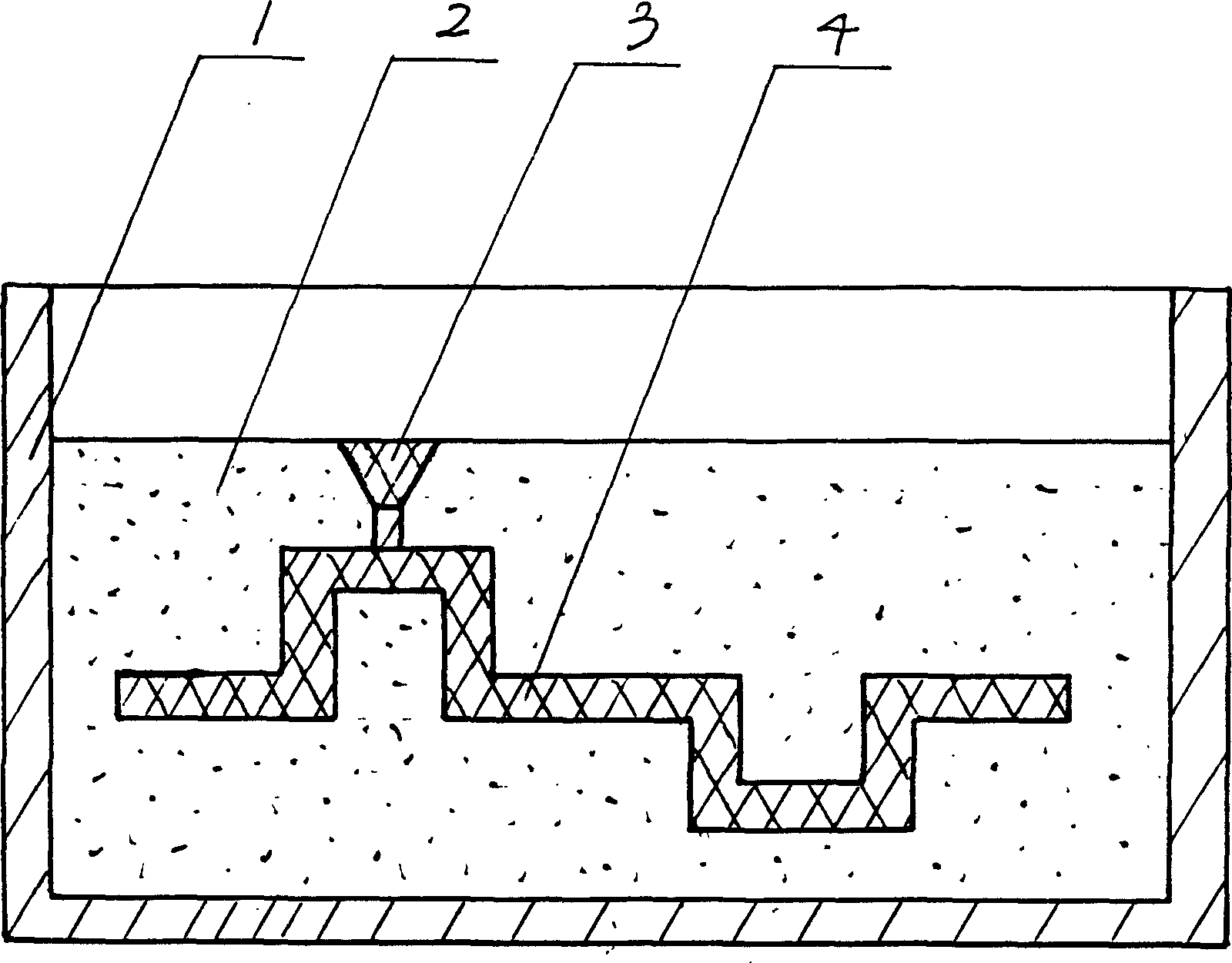

[0009] The working principle of the mold is: the mold body (4) is buried in the casting box (1) and compacted, the upper plane of the sprue mold (3) is flush with the upper surface of the molding sand in the casting box, and the molten The molten iron is aligned with the gate mold (3) and can be cast directly; at this time, the gate mold (3) and the mold body (4) melt rapidly and become gas volatilization, and the molten iron flows into the mold body (4) in the molding sand in sequence. In the space, after the molten iron is filled, it can be formed into a casting body.

[0010] In the figure, the molding sand (2) in the casting box (1) is the same as the conventional molding sand without any change, and the grain size of the molding sand (2) is determined according to the requirements of precision casting sand, and the finer grain size is required for high precision.

[0011] In the figure, the sprue mold (3) is in the shape of a funnel with a large top and a small bottom, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com