Anti-aging escalator roller

An escalator and anti-aging technology, which is applied to escalators, rotating parts that resist centrifugal force, bearings, etc., can solve the problems of easy hydrolysis reaction and poor damp heat aging resistance, and achieve excellent roller performance and strong damp heat aging resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

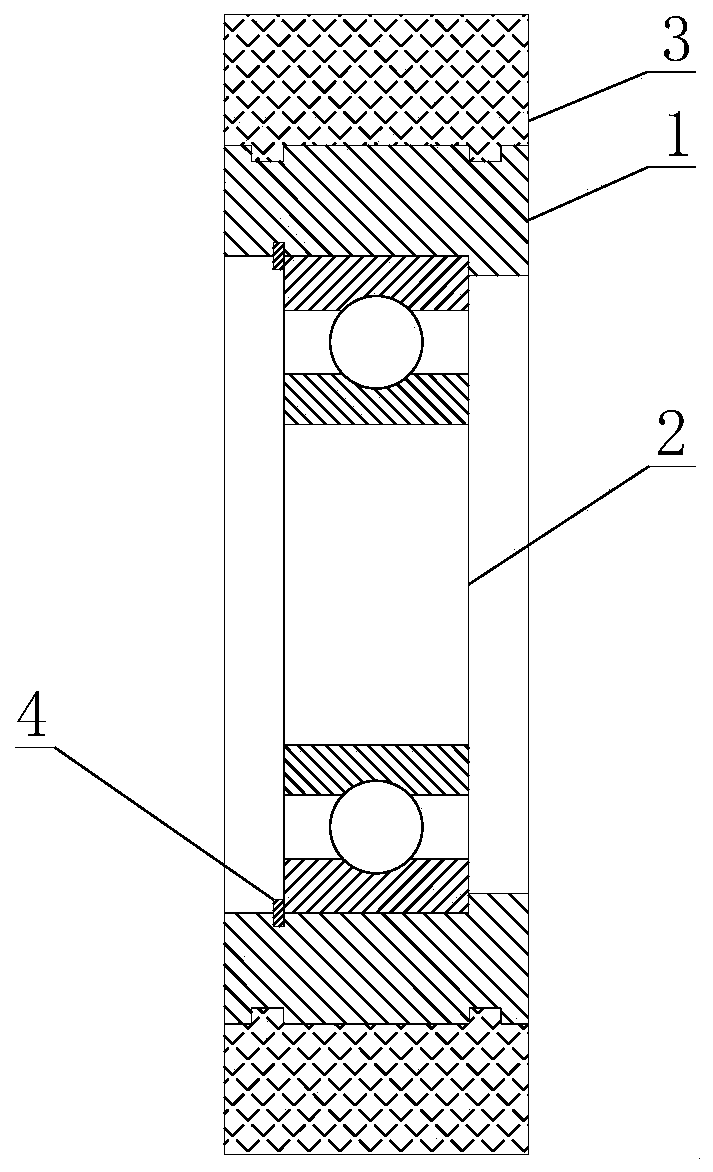

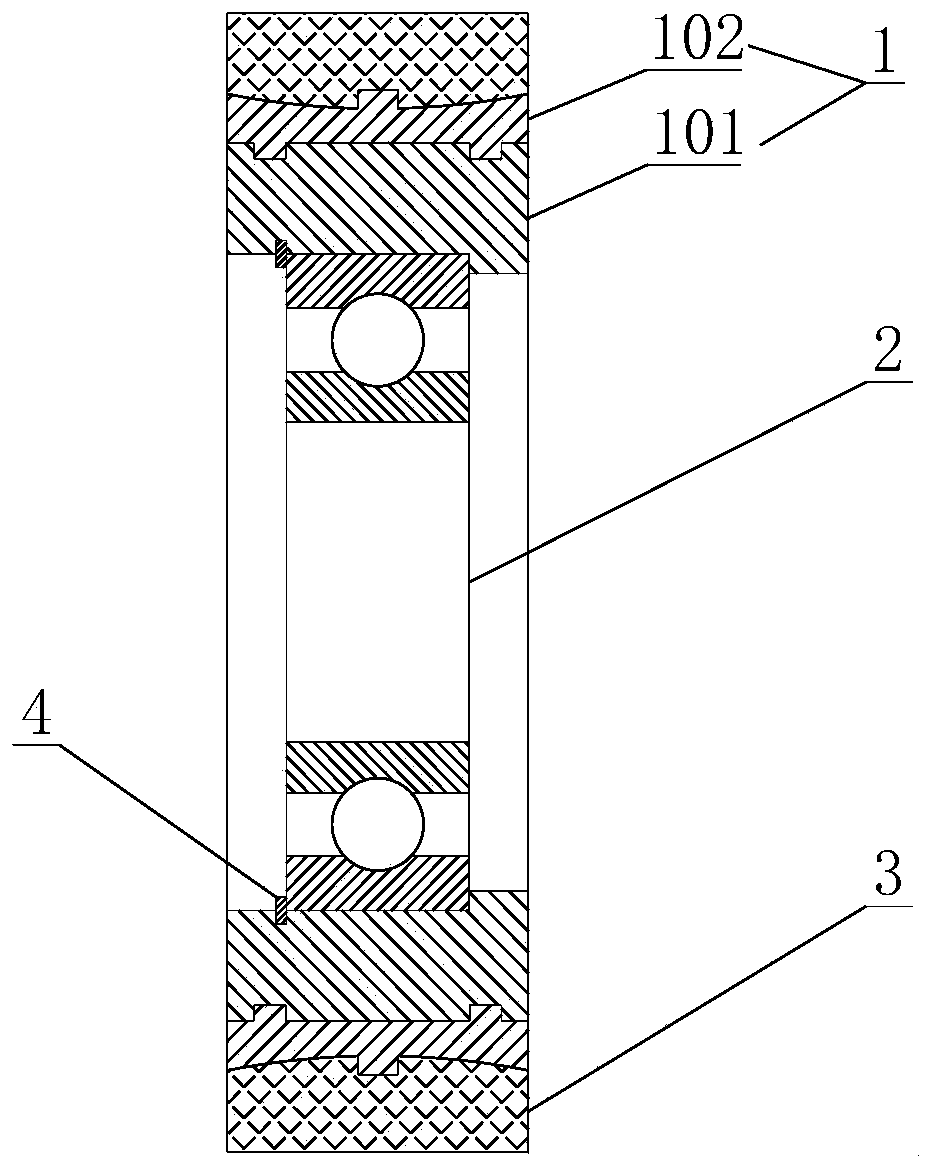

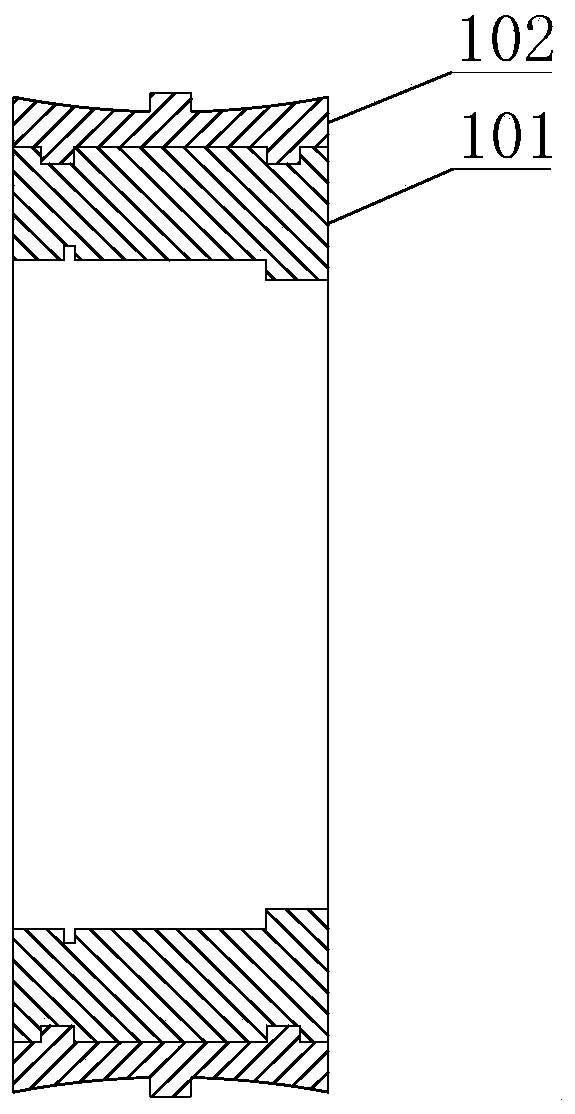

[0032] See figure 1 Same as the prior art, the anti-aging escalator roller of this embodiment is composed of a hub 1, and a bearing 2 and a rim 3 respectively arranged on the inner and outer rings of the hub 1; wherein, the hub 1 adopts Made of aluminum alloy.

[0033] Different from the prior art, in this embodiment, the rim 3 is injection-molded with a thermoplastic elastomer newly developed for subway escalators.

[0034] The manufacturing process of the roller is as follows:

[0035] (1) Preparation of thermoplastic elastomer

[0036] The material formula of the thermoplastic elastomer in this embodiment is composed of a main material and an auxiliary material. In parts by weight, the main material is: 100 parts of polyether TPU, 35 parts of ABS resin, 10 parts of macromolecular coupling agent; and auxiliary material: carbon 1 part of black, 0.05 part of antioxidant, 0.03 part of light stabilizer.

[0037] Among them: Polyether TPU is Bayer (Desmopan) 955U; ABS resin is TAIRILAC A...

Embodiment 2

[0045] The difference from Example 1 is that, in this example, the material formula of the thermoplastic elastomer is calculated in parts by weight. The main ingredients are: 100 parts of polyether TPU, 20 parts of ABS resin, 7 parts of macromolecular coupling agent; : 3 parts of carbon black, 0.1 part of antioxidant, 0.02 part of light stabilizer.

Embodiment 3

[0047] The difference from Example 1 is that in this example, the material formula of the thermoplastic elastomer is calculated in parts by weight. The main materials are: 100 parts of polyether TPU, 30 parts of ABS resin, 8 parts of macromolecular coupling agent; : 2 parts of carbon black, 0.07 parts of antioxidants, 0.03 parts of light stabilizers.

[0048] The anti-aging escalator rollers prepared in Examples 1-3 were tested in accordance with the China Elevator Association standard T / CEA 301-2019 "Technical Specifications for Escalators for Metro". The results show that the rollers of the present invention comply with T / CEA 301- 2019 requirements, and excellent performance.

[0049] Table 2: Test results of Examples 1-3

[0050]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com