A kind of adhesive-free and heat and humidity resistant solar battery back sheet and its manufacturing method

A solar cell and adhesive-free technology, which is applied in the field of solar backplanes, can solve the problems of poor UV resistance of AAA backplanes, deterioration of solar battery performance, pulverization and cracking, etc., and achieves good interlayer connection and is conducive to environmental protection , The effect of productivity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-2、4-6

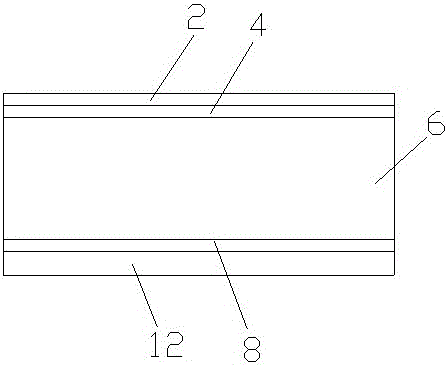

[0055] Such as figure 1 As shown, an adhesive-free and heat-resistant solar cell backsheet is composed of a weather-resistant layer 2 , a first connection layer 4 , a structural reinforcement layer 6 , a second connection layer 8 and a reflective layer 12 sequentially compounded.

[0056] The weather-resistant layer 2 is a polyvinylidene fluoride (PVDF) film, or a fluorine material alloy layer modified with an inorganic material. The fluorine material alloy layer modified by inorganic materials is first made of fluorine material alloy and then modified by inorganic materials. Specifically, in Examples 4 and 6, polyvinylidene fluoride (PVDF), polymethyl methyl acrylate (PMMA) and titanium dioxide (TiO 2 ) blended.

[0057] The first connecting layer 4 is modified by blending a silane coupling agent and an ethylene acrylate copolymer, and the weight ratio of the silane coupling agent and the ethylene acrylate copolymer is 0.05-5:100, more specifically 0.1- 4:100.

[0058] Th...

Embodiment 3

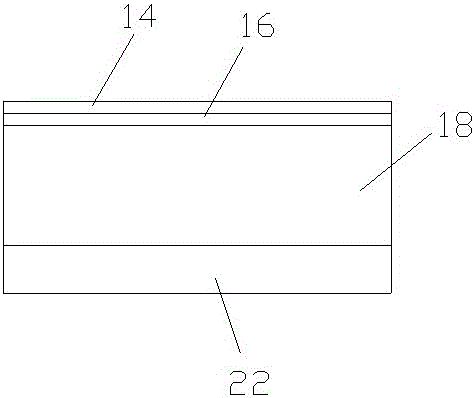

[0063] Such as figure 2 As shown, an adhesive-free and heat and humidity resistant solar cell backsheet differs from Embodiments 1-2 and 4-6 in that:

[0064] It consists of a weather-resistant layer 14, a first connection layer 16, a structural reinforcement layer 18 and a reflective layer 22 that are sequentially compounded.

[0065] The weather-resistant layer 14 is a polyvinyl fluoride (PVF) film.

[0066] The structural reinforcement layer 18 is made of modified polypropylene, which is modified by blending polypropylene, thermal stabilizers and inorganic fillers.

[0067] Reflective layer 22 is made of low density polyethylene (LLDPE), ethylene propylene diene monomer (EPDM), anti-ultraviolet stabilizer and titanium dioxide (TiO 2 ) blended and modified.

[0068] The thicknesses of the weather-resistant layer 14 , the first connection layer 16 , the structural reinforcement layer 18 and the reflective layer 22 of the backplane are 25um, 40um, 150um, and 150um, respect...

Embodiment 1-6

[0069] See Table 1 for the specific parameters of the solar backboards of Examples 1-6.

[0070] A kind of manufacturing method of the present invention is described below with the manufacturing method of embodiment 1-3 solar back plate, and this method comprises the following steps:

[0071] (1) The materials of the first and second connection layers, the material of the structural reinforcement layer and the material of the reflective layer are respectively granulated by an extruder to obtain the plastic particles of the first and second connection layers, the plastic particles of the structural reinforcement layer and the reflective layer The plastic particles are used for backup; the fluorine film used as a weather-resistant layer is prepared by a common method in the industry for use.

[0072] (2) The plastic particles of the first and second connection layers, the plastic particles of the structural reinforcement layer and the plastic particles of the reflective layer pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com