RO membrane filter element assembly

A technology of core components and membrane filtration, which is applied in the field of RO membrane filter components, can solve problems such as inconvenient disassembly methods, and achieve the effect of reducing the difficulty of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

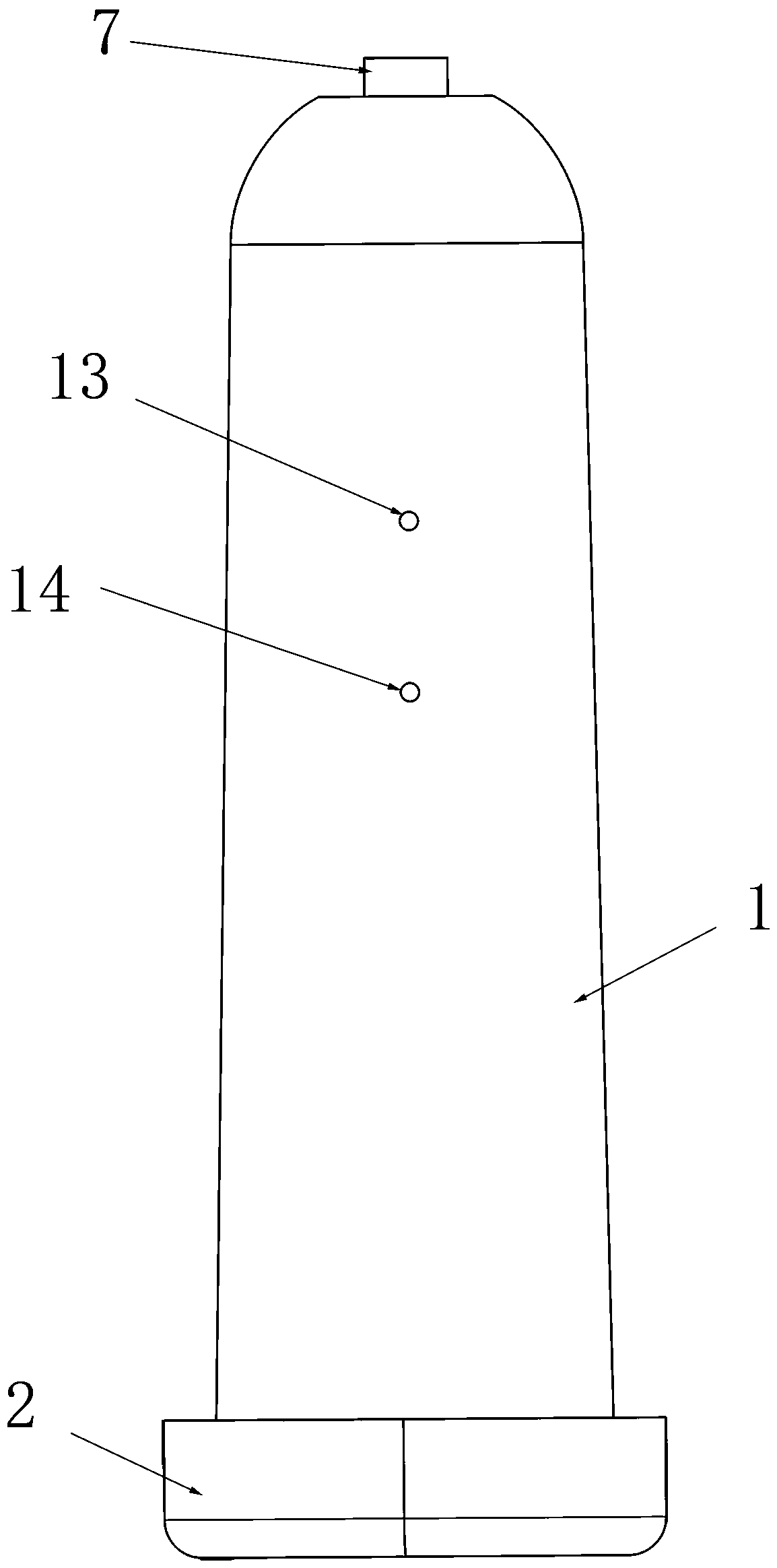

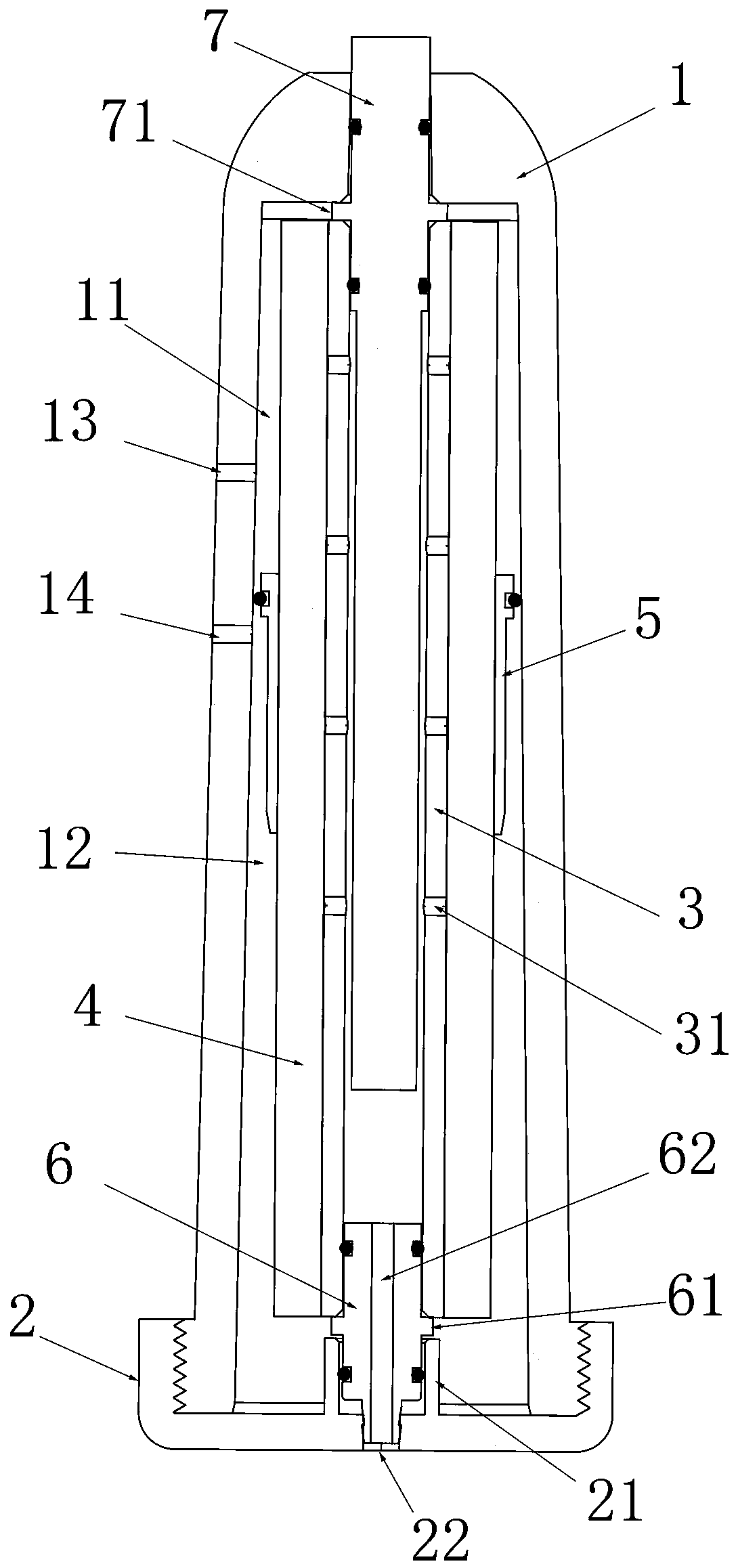

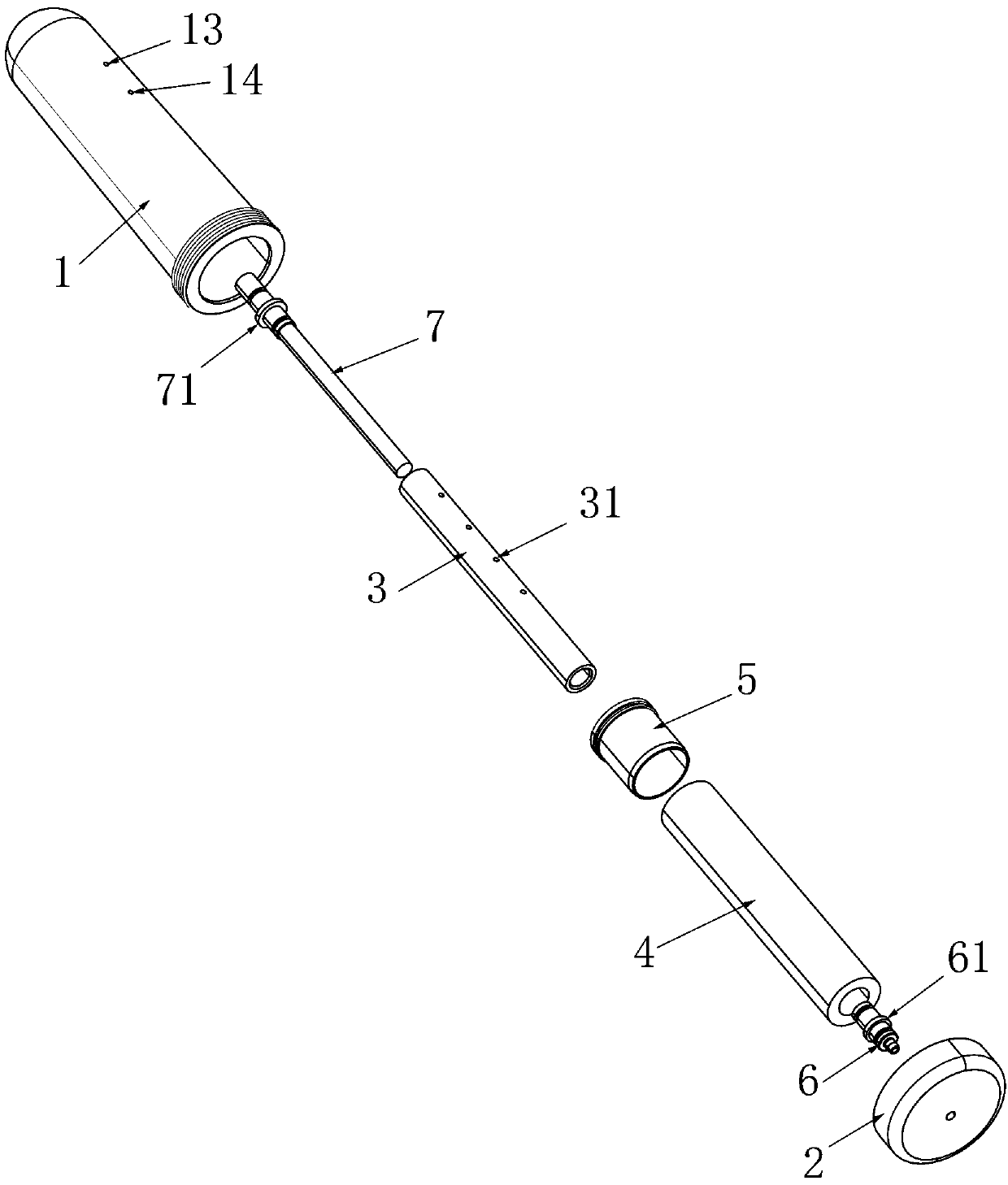

[0017] See attached picture. The RO membrane filter element assembly of this embodiment includes an RO membrane filter element, a filter bottle 1, and a filter bottle cap 2. The RO membrane filter element is installed in the filter bottle, and the filter bottle 1 and the filter bottle cap 2 are fixedly connected by threads. There is an installation groove 21, and the bottom of the installation groove is provided with a pure water port 22; the bottom of the filter bottle 1 is provided with a through hole.

[0018] The RO membrane filter element includes a central tube 3 and a membrane 4 wound on the central tube. A pure water channel is arranged in the membrane, and a waste water channel is formed between adjacent membranes; a pure water concentration flow channel is arranged inside the central tube. and a plurality of pure water through holes 31 connecting the pure water channel and the pure water concentrated flow channel, the pure water through holes are distributed along th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com