Ship loader pitching hinge point bearing replacement method

A replacement method and ship loader technology, which is applied in loading/unloading, transportation and packaging, metal processing, etc., can solve problems such as bearing wear, bearing inner and outer ring fracture and damage, and increased gap between bearing and boom, so as to reduce replacement Difficulty, improvement of replacement efficiency, and improvement of work reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0036] In the present invention, unless otherwise stated, the used orientation words such as "up, down, left, and right" generally refer to up, down, left, and right in the drawings.

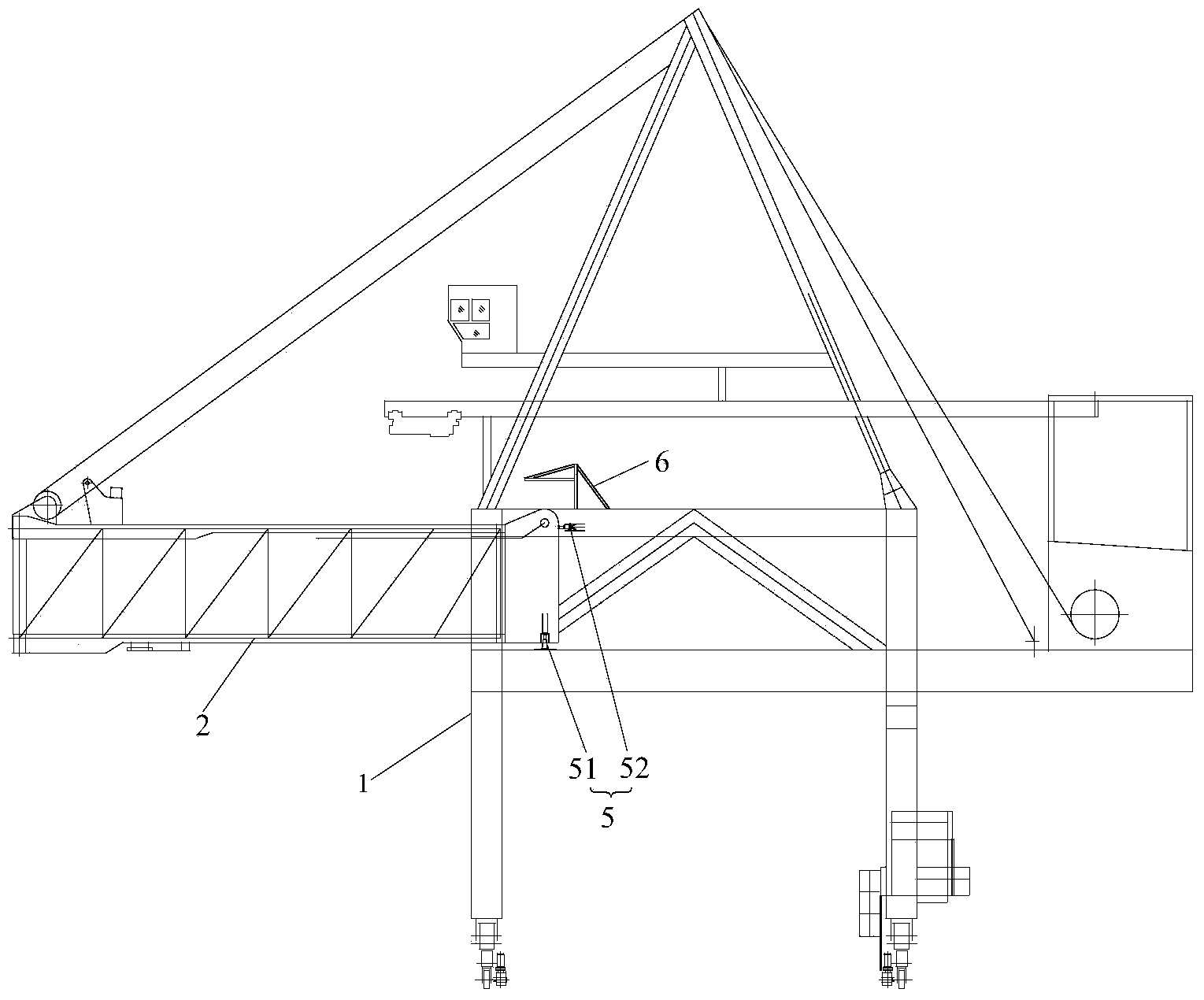

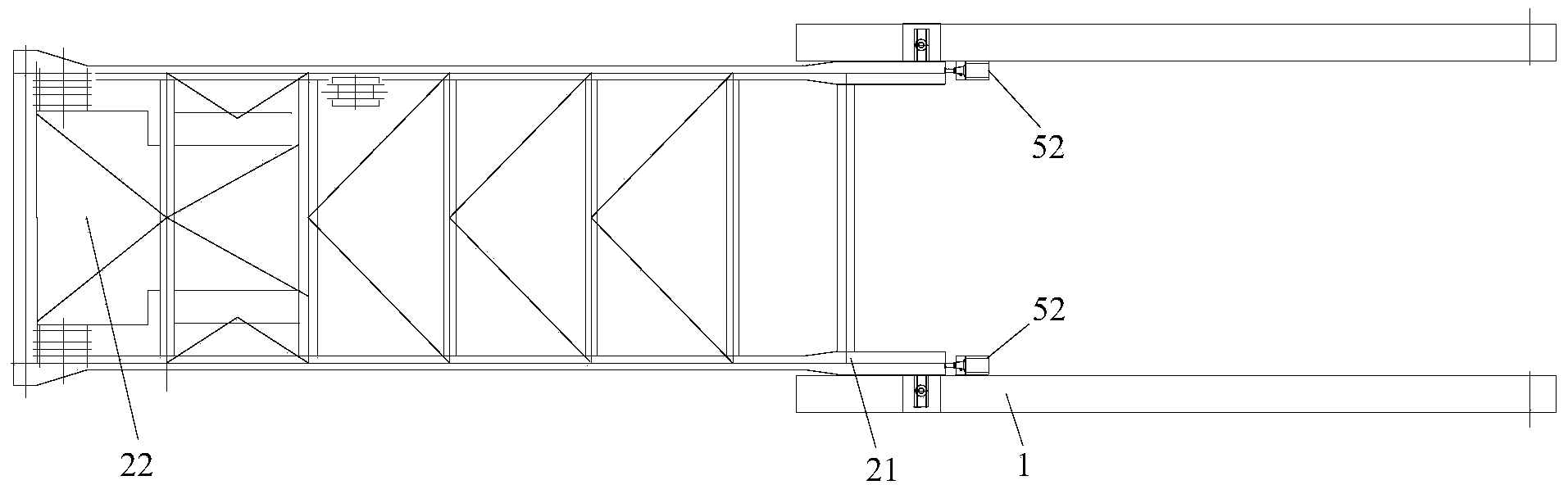

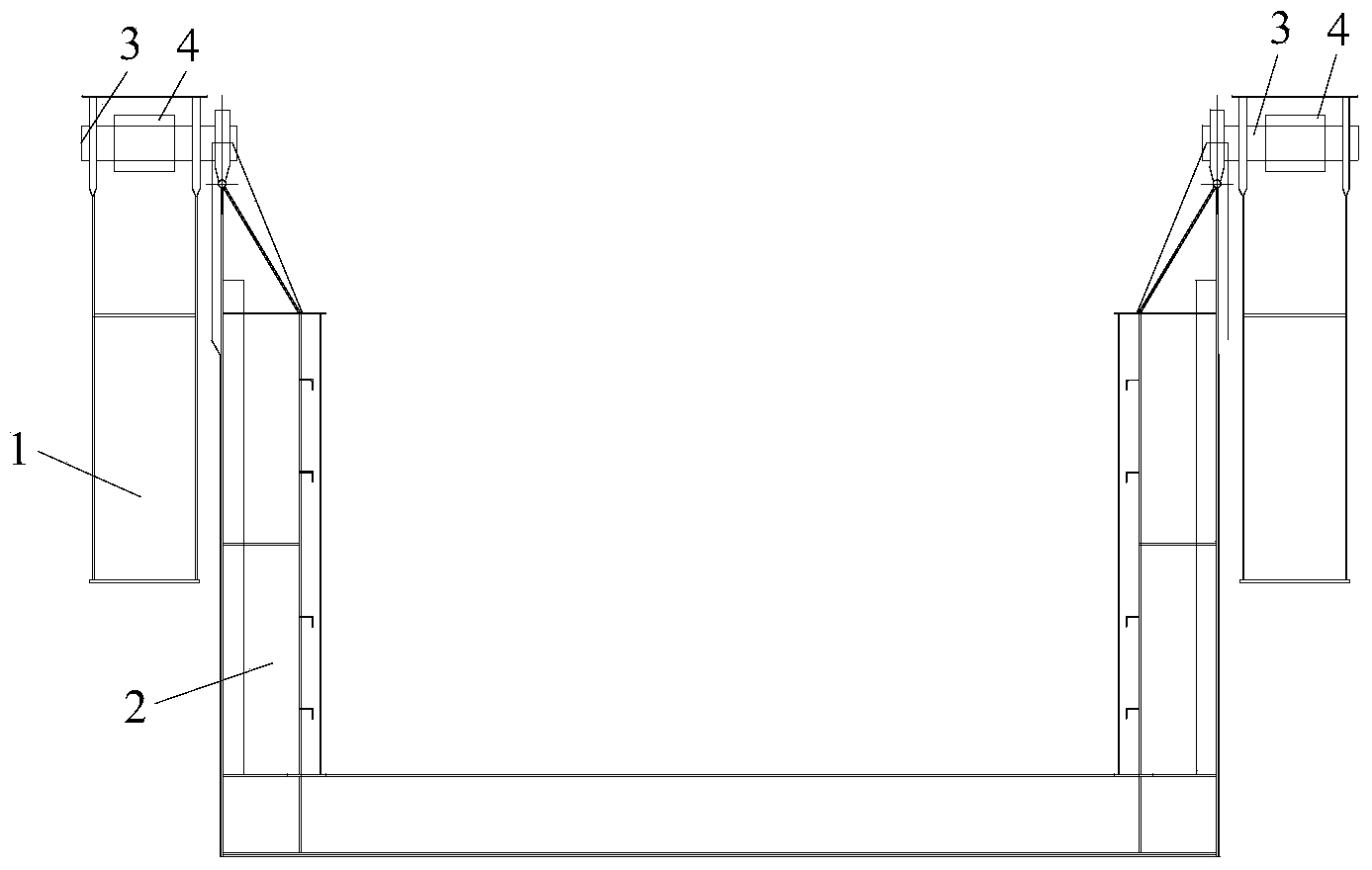

[0037] see Figure 1 to Figure 3 , the ship loader usually includes a mast 1 and a cantilever 2, the tail of the cantilever 2 is hinged to the mast 1 through a pin 3, and a bearing 4 is sleeved on the pin 3, more specifically, the bearing 4 is installed In the lug plate of door frame 1. Depend on image 3 It can be seen that the pin shaft 3 is mainly subjected to the force of the cantilever 2 . Therefore, in order to be able to replace worn bearings with new ones to improve th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com