A kind of rare earth nano hydrogen storage alloy for catalyzing the hydrogen absorption and desorption of organic hydrogen storage liquid and its preparation method

A hydrogen storage alloy and organic technology, applied in the field of rare earth nanometer hydrogen storage alloy and its preparation, can solve the problems of complex preparation process and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

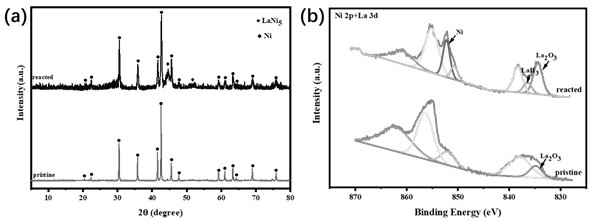

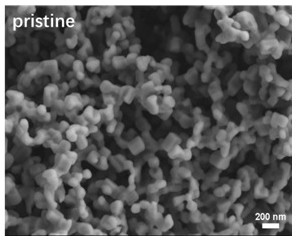

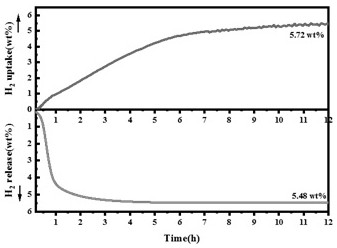

Embodiment 1

[0036] Add 0.371 g LaCl to the beaker 3 ∙7H 2 O and 1.307 g NiCl 2 ∙6H 2 O, stirring and dissolving in 10 mL deionized water, adding 10 mL 4 mol / L concentrated NaOH solution dropwise under vigorous stirring to obtain a mixed hydroxide precursor; centrifuging, and washing the obtained isolate with deionized water for three times and then dried overnight in an oven at 80 °C; the dried mixed hydroxide precursor was mixed with 4 g KCl and 1.5 g CaH in a glove box 2 Grind and mix to obtain mixed powder, then transfer to a crucible, and reduce in a tube furnace with protective gas Ar atmosphere at 700 °C for 2 h to obtain a hardened solid mixture, which is washed with 0.1mol / L dilute acetic acid under the protection of protective gas Ar Three times, CaO produced by the dissolution reaction, unreacted CaH 2 and KCl solid, and centrifuged, the separated precipitate was washed with water and ethanol respectively, and finally dried in a vacuum oven for later use, that is, a type of ...

Embodiment 2

[0041] Add 0.371 g LaCl to the beaker 3 ∙7H 2 O and 1.188 g NiCl 2 ∙6H 2 O, stirring and dissolving in 10 mL deionized water, adding 10 mL 4 mol / L concentrated NaOH solution dropwise under vigorous stirring to obtain a mixed hydroxide precursor; centrifuging, and washing the obtained isolate with deionized water for three times and then dried overnight in an oven at 80 °C; the dried mixed hydroxide precursor was mixed with 4 g KCl and 1.5 g CaH in a glove box 2 Grind and mix to obtain mixed powder, then transfer to a crucible, and reduce in a tube furnace with protective gas Ar atmosphere at 700 °C for 2 h to obtain a hardened solid mixture, which is washed with 0.1mol / L dilute acetic acid under the protection of protective gas Ar Three times, CaO produced by the dissolution reaction, unreacted CaH 2 and KCl solid, and centrifuged, the separated precipitate was washed with water and ethanol respectively, and finally dried in a vacuum oven for later use, that is, a type of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com