Roadbed maintenance device and method for road construction

A technology of roadbed and highway, applied in the direction of roads, roads, road repair, etc., can solve the problems of poor spraying method, low work efficiency, inconvenient operation, etc., and achieve the effect of simple and convenient control, high work efficiency, and reduction of collisions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

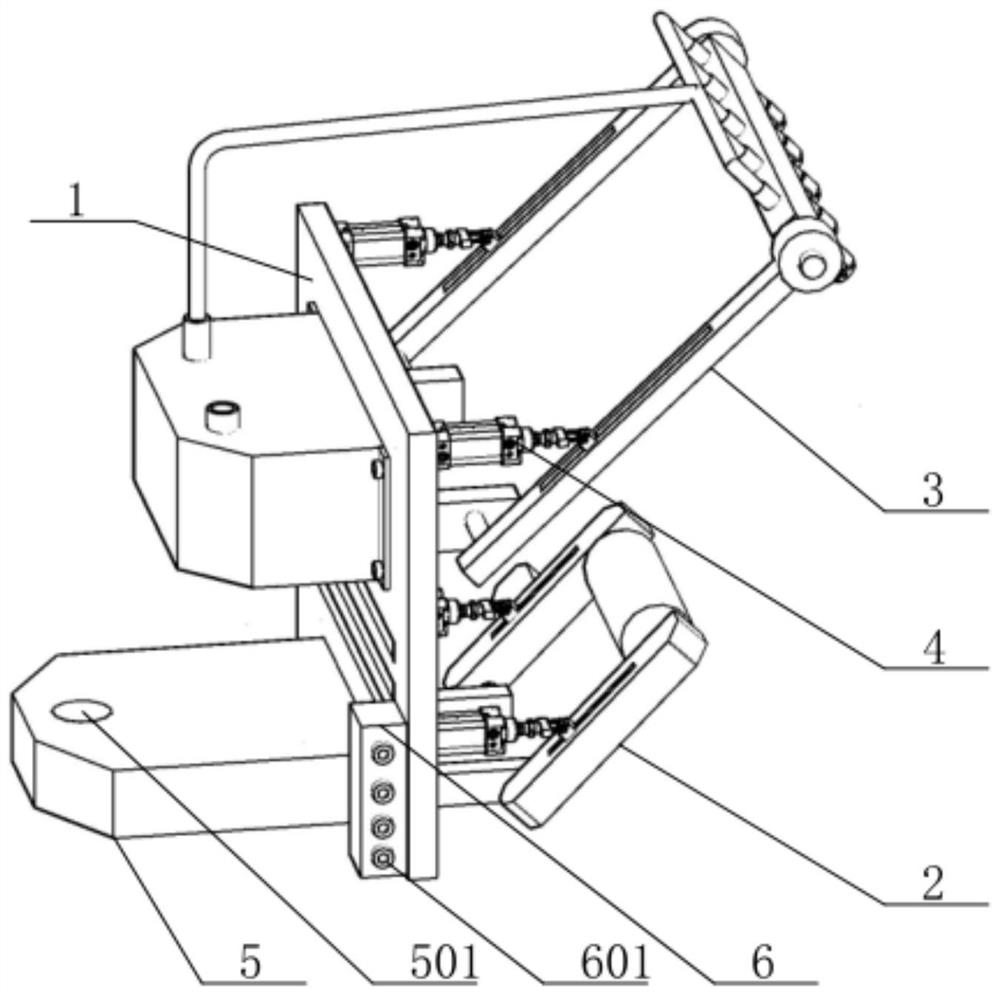

[0038] see figure 1 —8. Roadbed maintenance device for road construction, including installation board 1, laying mechanism 2, spraying mechanism 3, and push-pull mechanism 4;

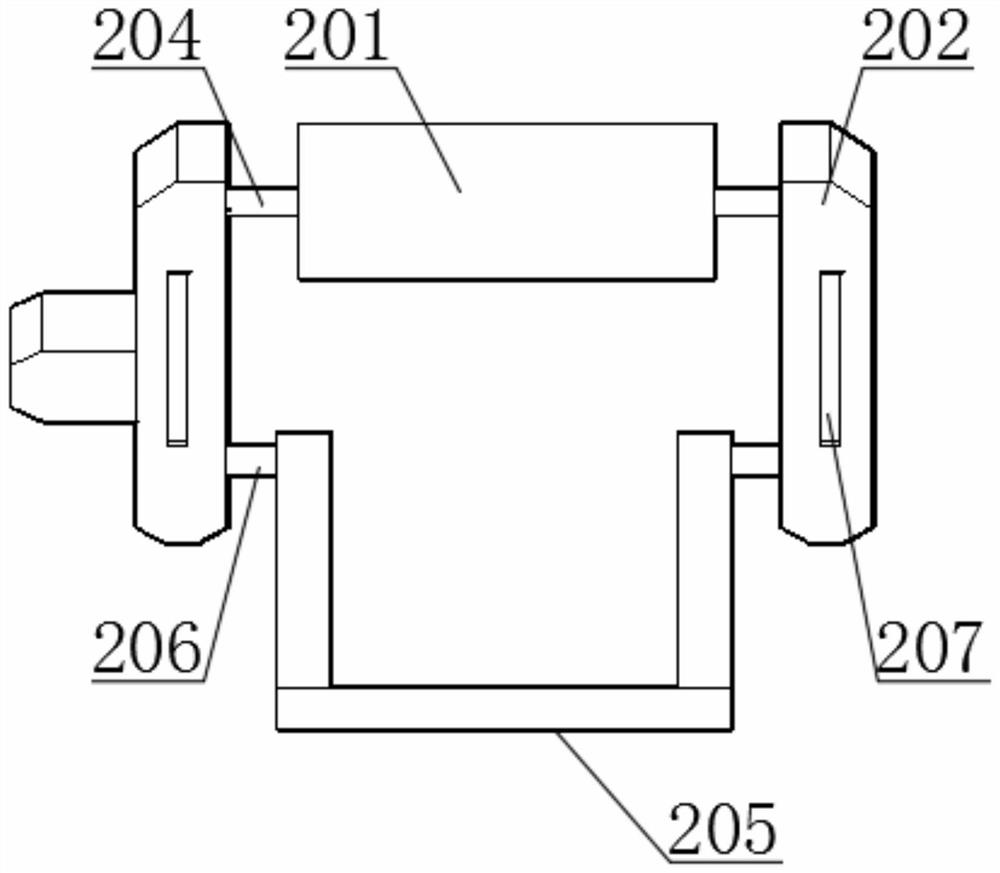

[0039]The laying mechanism 2 includes a drum 201, a side frame 202, and a rotating motor 203. Felt is rolled on the upper part of the drum 201. Both ends of the drum 201 are fixedly connected to a No. 1 rotating shaft 204. Two groups of No. 1 rotating shafts 204 are respectively connected to a group of side frames through bearings. In 202, a rotating motor 203 is fixedly installed on the side of one group of side frames 202, and a protective shell is arranged on the outside of the rotating motor 203, and the rotating motor 203 is power-connected with the No. The motor 203 can drive the drum 201 to rotate, and the mounting plate 1 is fixedly connected with a No. 1 turret 205. Both sides of the No. 1 turret 205 are fixedly connected with a No. 2 rotating shaft 206, and the No. 2 rotating shaft 206 is resp...

Embodiment 2

[0043] see figure 1 —8. The roadbed maintenance device for road construction is basically the same as the first embodiment. What’s more, the mounting plate 1 is fixedly connected with the hanger 5 at the bottom of the water storage tank 304, and the hanger 5 is provided with a mounting hole 501. Frame 5 is used to fixedly install the maintenance device on the maintenance vehicle;

[0044] Further on the mounting plate 1, one side of the hanger 5 is fixedly installed with a control mechanism 6. The control mechanism 6 includes a control shell and a controller with a single-chip microcomputer installed inside the control shell. The controller is connected to the rotating motor 203, The water pump and each group of hydraulic telescopic cylinders are connected to signal 401 to control their work;

[0045] Multiple sets of data connectors 601 are installed on the control shell, and the data connectors 601 are connected to the controller signal. There is a control panel in the cab ...

Embodiment 3

[0048] see figure 1 —8. Roadbed maintenance device for road construction. In Embodiment 1, the power connection between the rotating motor 203 and the No. 1 rotating shaft 204 adopts the following structure. The rotating shaft of the rotating motor 203 is fixedly connected with a No. 1 gear 7, and a gear 7 on the same side as it is The No. 2 gear 8 is fixedly connected to the No. 2 rotating shaft 204 , and the No. 1 gear 7 and the No. 2 gear 8 are connected through a chain 9 .

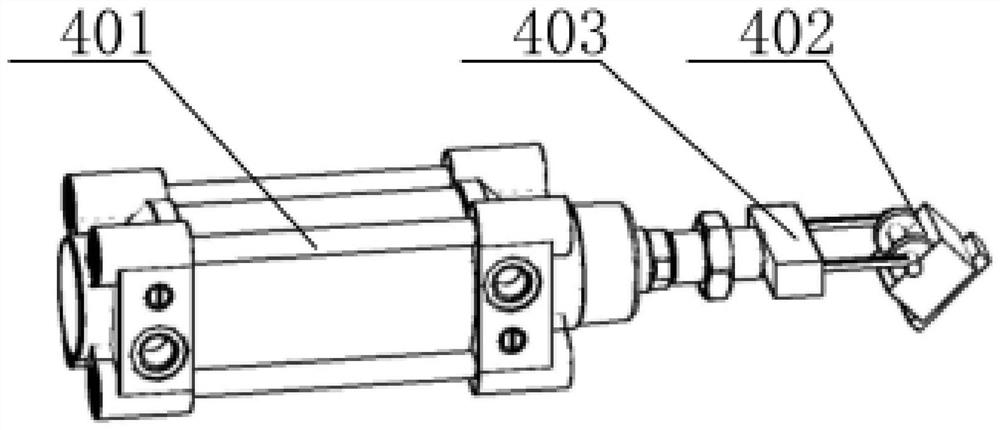

[0049] In the first embodiment, the sliding block 402 includes a bottom sliding block 40201, an upper sliding block 40202, and a rotating block 40203. The upper part of the bottom sliding block 40201 is fixedly connected with the upper sliding block 40202, and the symmetrical fixed connection of the upper sliding block 40202 has two sets of rotating blocks. block 40203, and is slidably connected in the No. 1 chute 207 or No. 2 chute 309 by the bottom slider 40201, and the connecting piece 403 includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com