Moisture-trapping loess foundation pit anti-slip electric sintering supporting pile

A technology of collapsible loess and electric sintering, which is applied in soil protection, foundation structure engineering, sheet pile walls, etc., can solve the problems of construction period impact, time-consuming, huge increase in engineering earthwork, etc., and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

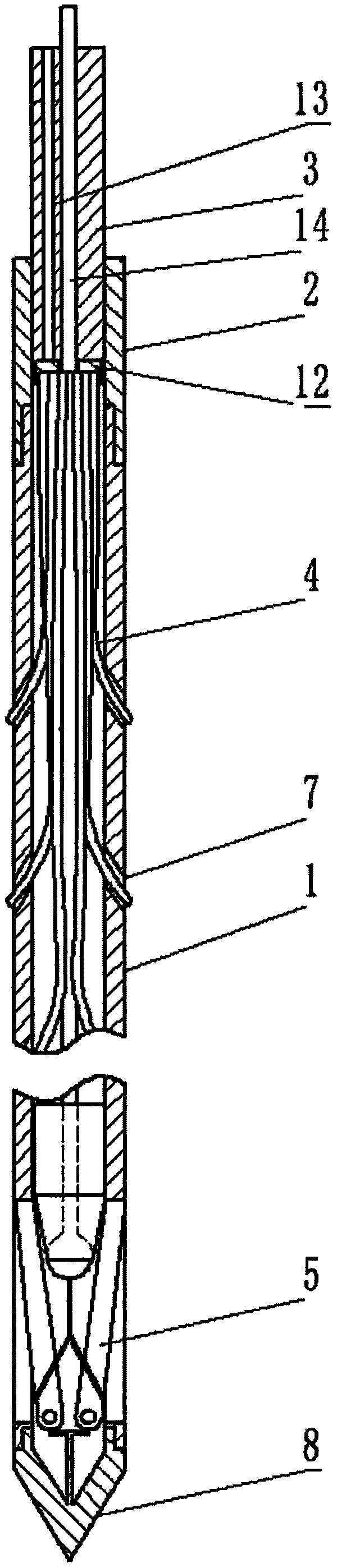

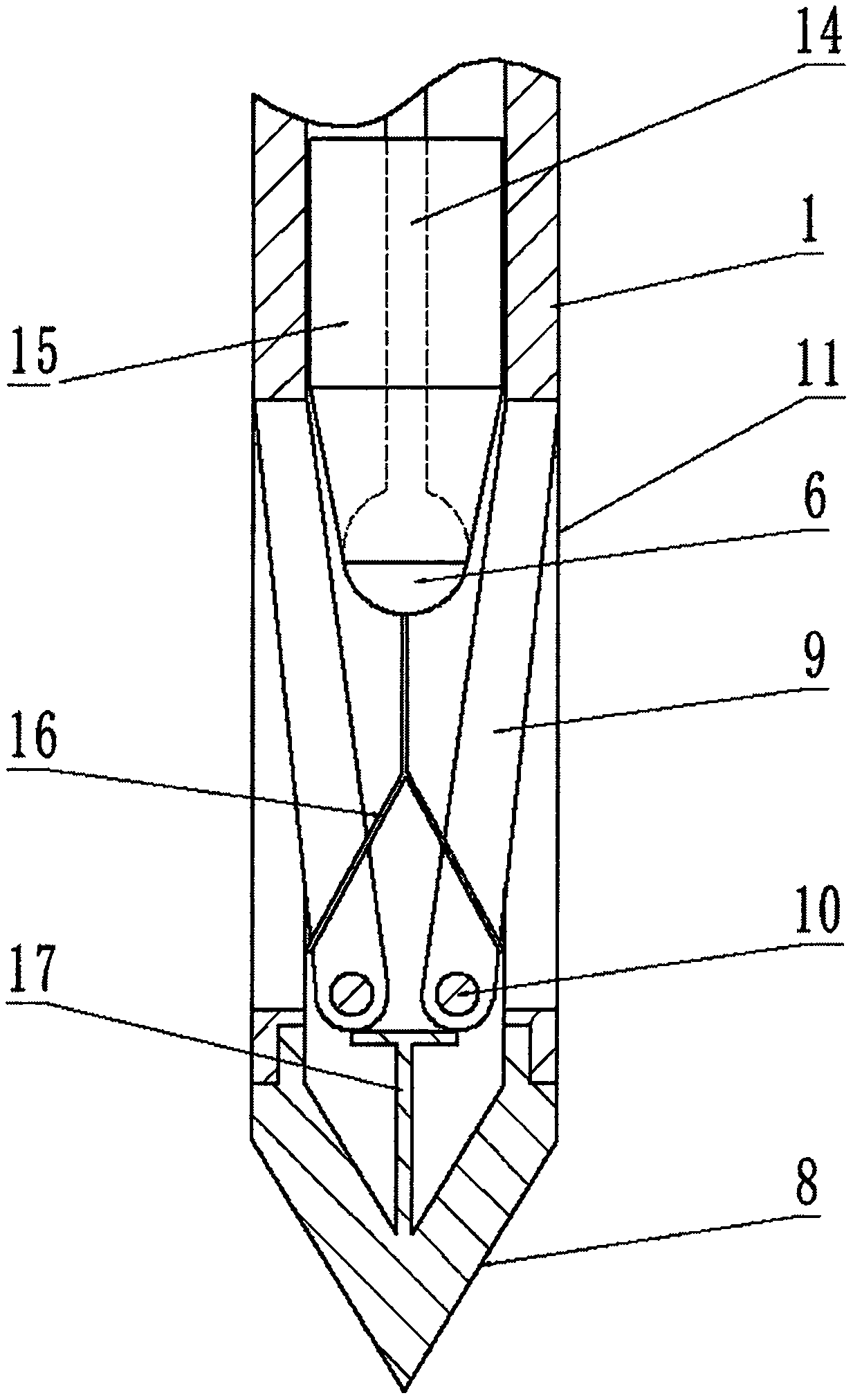

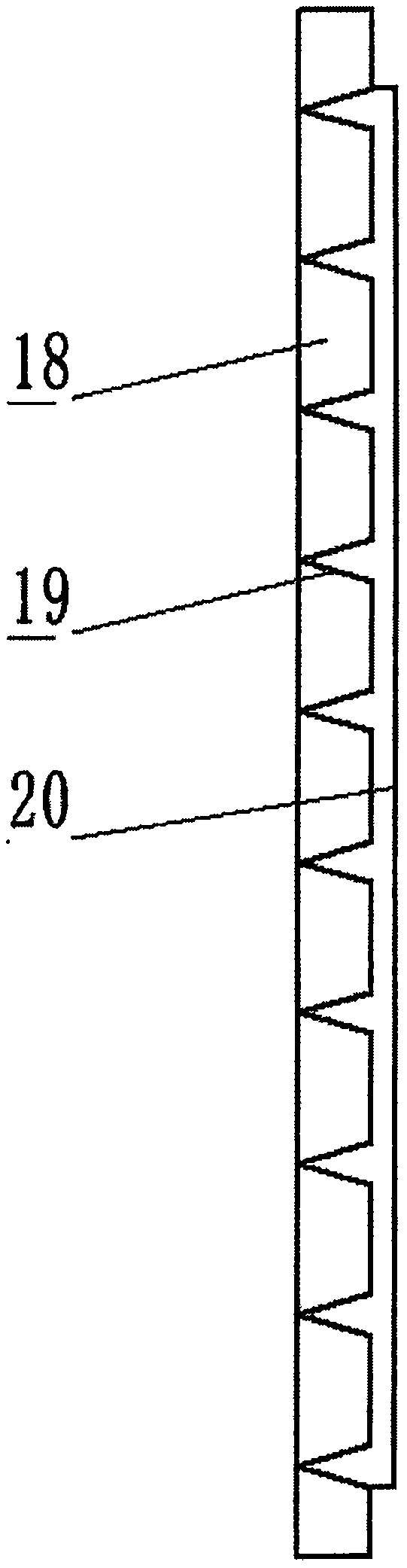

[0022] The collapsible loess foundation pit anti-slip and collapse electric sintering support pile includes a main pile pipe 1, an upper connection pile pipe 2, a core pipe 3, a steel wire electrode 4, an expansion anchor top 5 and an expansion anchor top electric brush ball 6.

[0023] Among them, the main pile pipe 1 is a plastic steel round pipe, and a plurality of electrode holes 7 are arranged on the side. 1 The anchor tip 8 at the lower end, at least two anchor rods 9 and the anchor rod hinge shaft 10 are composed. 1, the main pile pipe 1 side wall is provided with an anchor groove 11 at the anchor rod 9, the length of the anchor groove 11 is equal to the projection length of the front side of the anchor rod 9, the anchor point 8 is threaded with the main pile pipe 1, and the main pile pipe 1 is connected with the main pile pipe 1. The upper connecting pile pipe 2 is threaded.

[0024] The core tube 3 is a cylindrical plastic part, which is set in the upper connection p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com