A construction method for laying floor tiles for building floor decoration

A technology of floor decoration and construction method, which is applied in the directions of architecture, building structure, floor, etc., can solve the problems of subsidence of floor tile laying, increase of floor tile cost, frequent use of workers' arms and waist strength, etc. The effect of smooth operation and increased cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

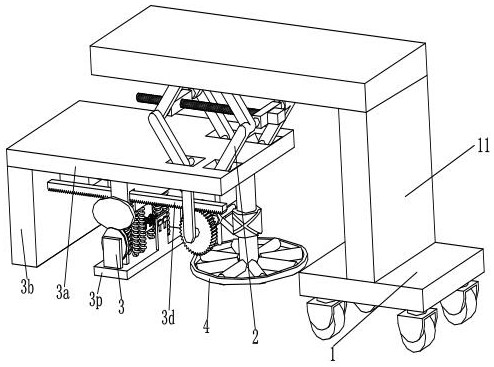

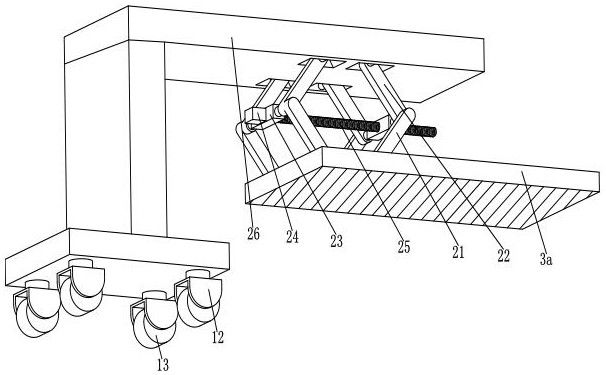

[0033] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

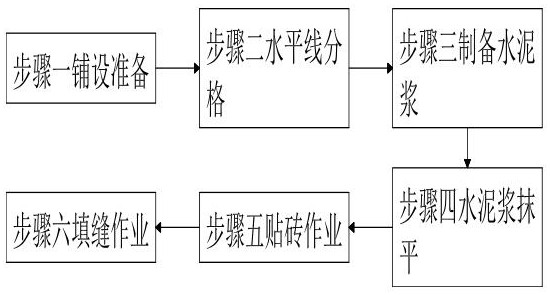

[0034] like Figure 1 to Figure 7 As shown, a construction method for laying decorative floor tiles on the building ground is characterized in that it mainly includes the following manufacturing steps:

[0035] Step 1, laying preparations, manually clean and check the floor of the room where the decorative floor tiles are pasted, manually use cleaning tools to clean up the sundries and floating sand on the floor of the room, and ensure that there are no cracks on the laying base, and the laying Fully wet the base layer to obtain a clean room with the base layer;

[0036] Step 2, divide the horizontal line, artificially play the horizontal line around the room with the clean base layer obtained in step 1, perform pre-arrangement according to the horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com