Vibration test clamping tool

A vibration test and clamping technology, which is applied in the direction of vibration test, measuring device, machine/structural component test, etc., can solve the problems of increasing workload, reducing efficiency, wasting manpower and material resources, etc., to improve accuracy and ensure accuracy , The effect of convenient disassembly and clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

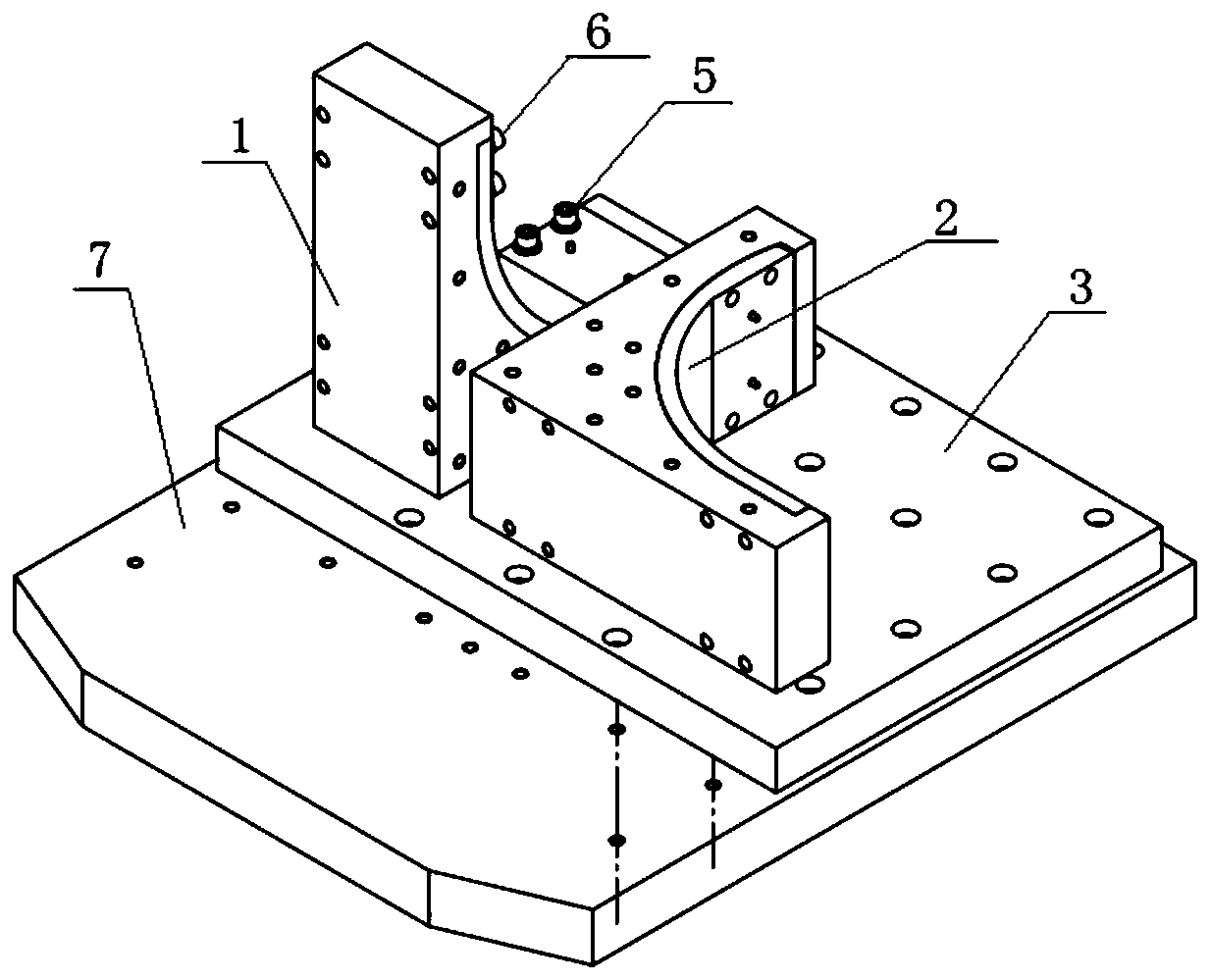

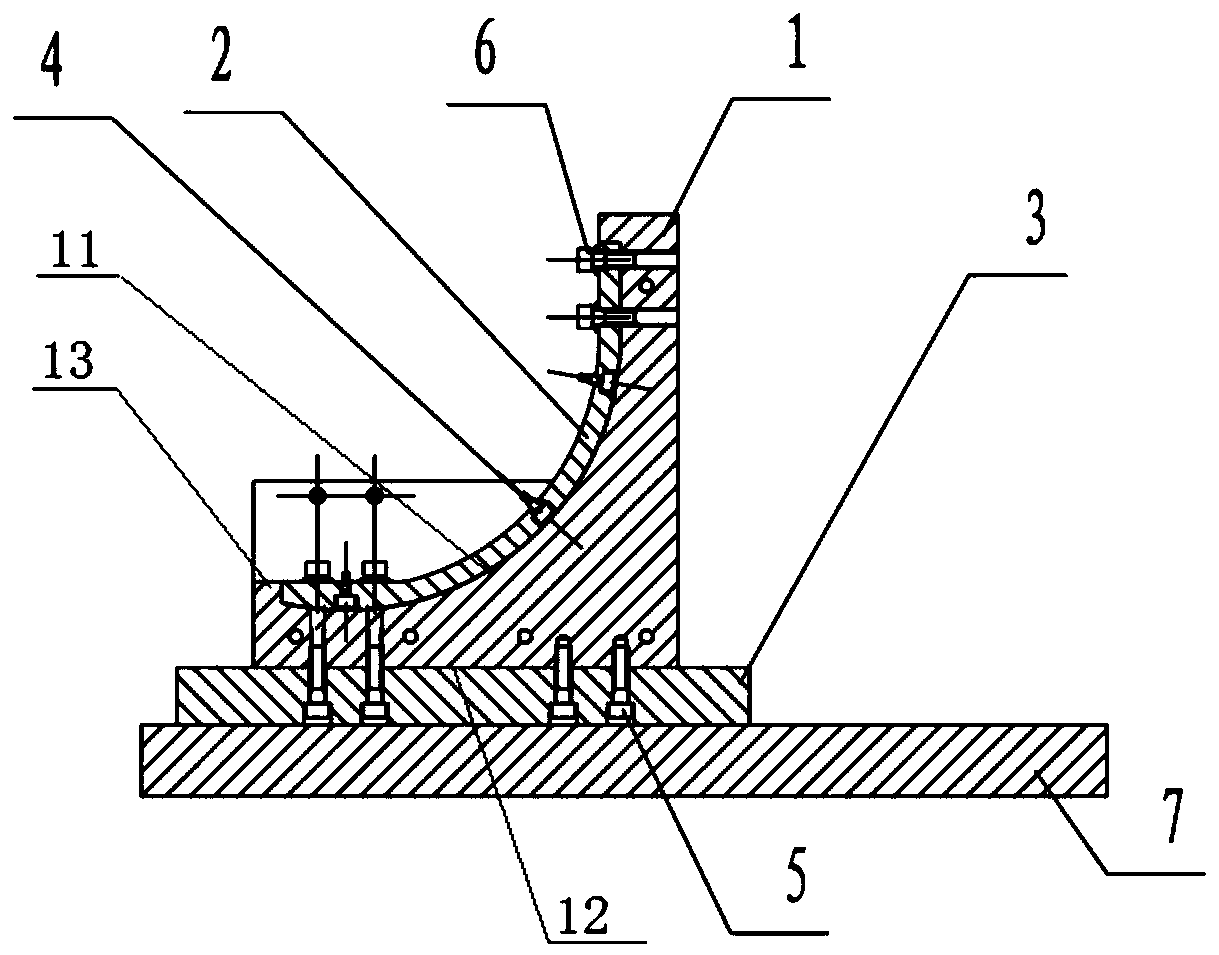

[0023] Since the connection surface of some vibration test products is a curved surface structure, if the product to be tested is directly connected to the equipment transfer base plate for vibration test, the connection and disassembly of the fixed support will require a lot of work, the operation efficiency is not high, and it is inconvenient to operate . In order to solve this problem, this application designs a fixed support whose connection surface matches the product connection surface, that is, as figure 1 , 2 As shown, the connection surface a11 of the fixed support 1 is a curved surface structure, and the product connection block 2 with an arc structure matching the structure of the connection surface a11 is connected to the fixed support 1. During the specific operation, the product connection block 2 and the product It is connected as a whole by fixing screws 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com