Fruit corer

A technology for nuclear device and fruit, which is applied in the direction of fruit de-pitting device, fruit de-pitting device, measuring device, etc., can solve the problem of increasing the contact area between fruit pulp and outside air, reducing the accuracy of pesticide residues in fruit, and being easy to dig and unclean. Fruit pits and other problems, to achieve the effect of convenient collection, easy operation, and maintaining integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

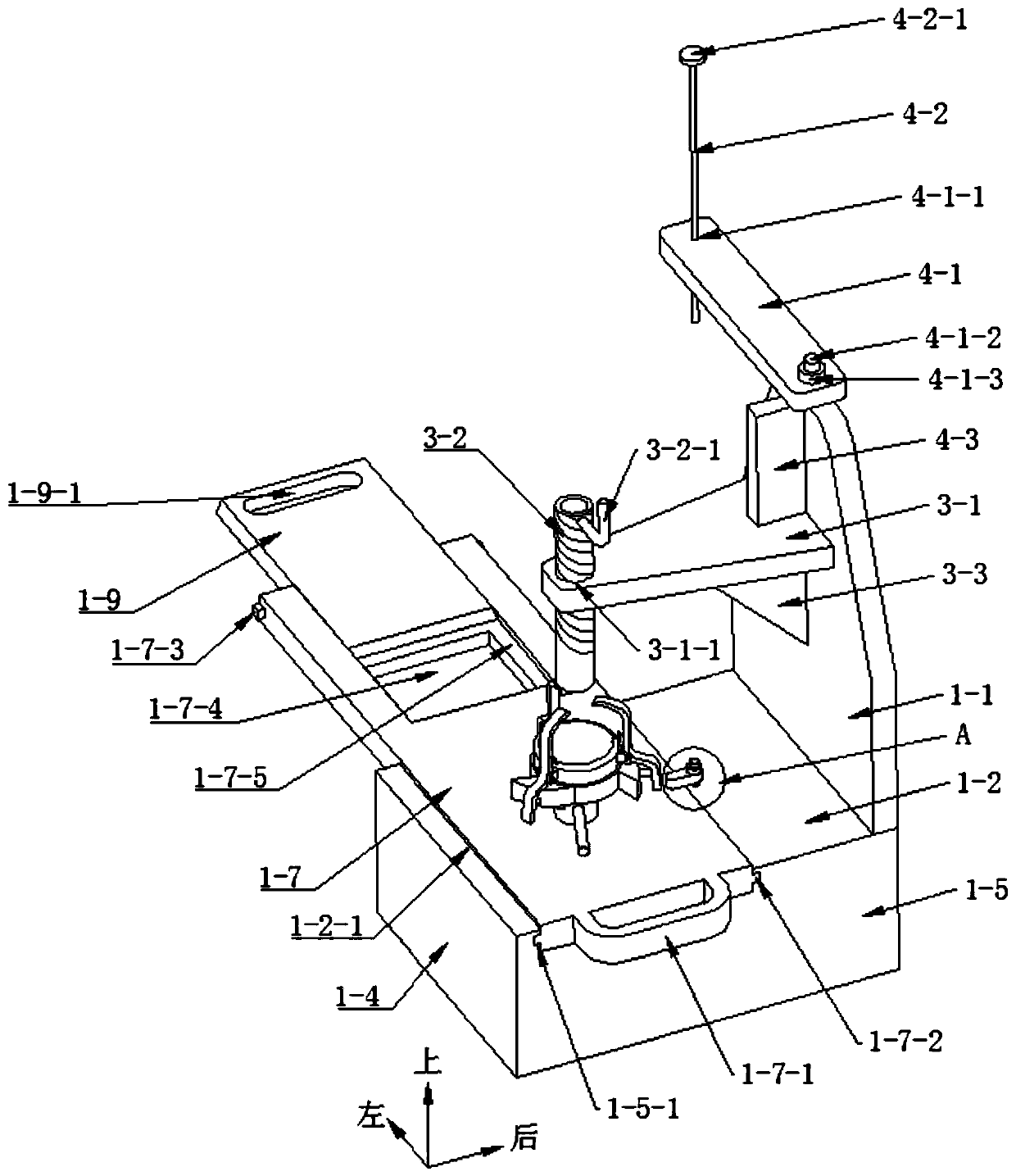

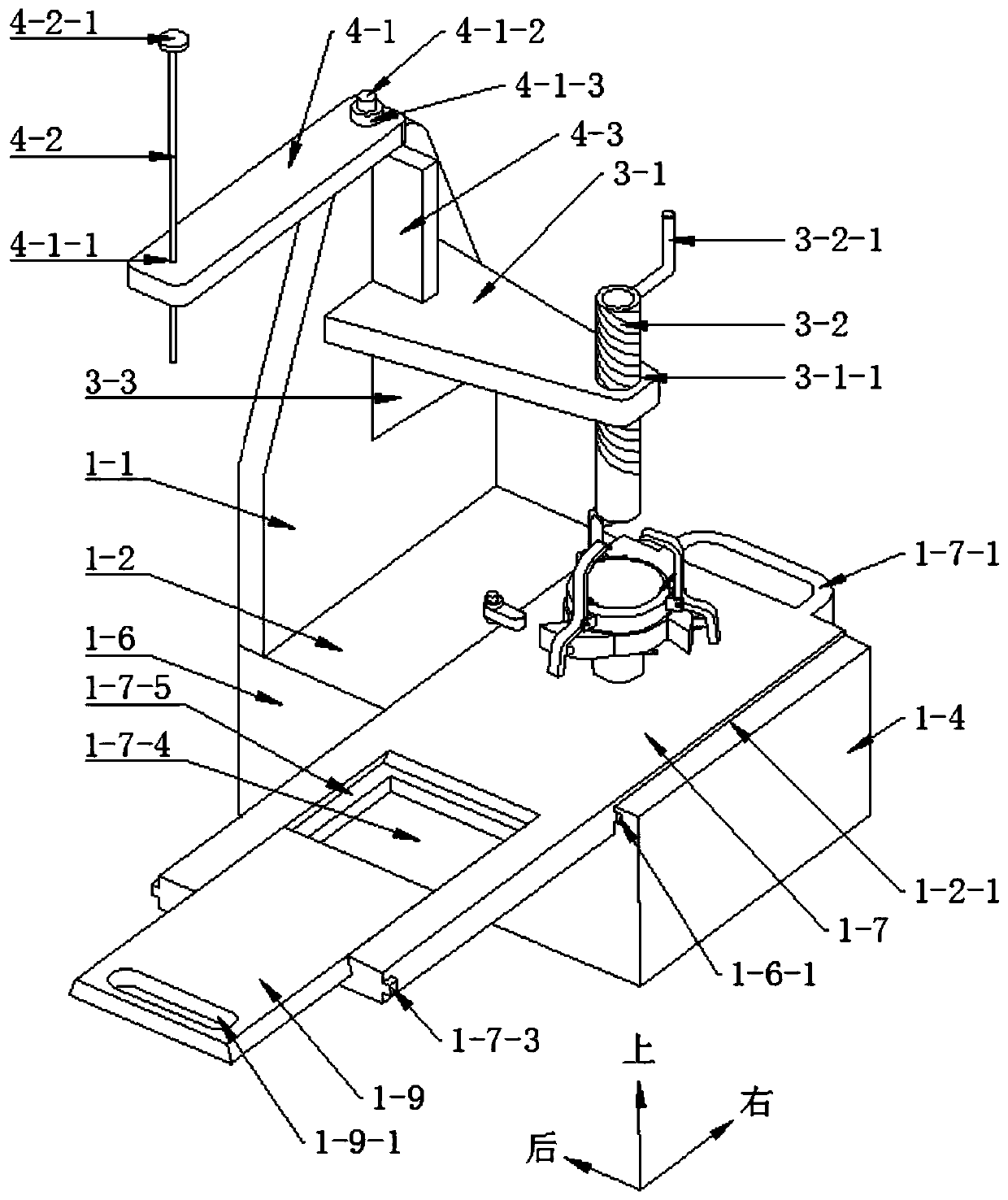

[0066] A fruit pitting device, such as Figure 1-6 As shown, it includes the fuselage, clamping assembly, de-nucleating assembly, and de-nucleating assembly.

[0067] The fuselage includes a vertical plate 1-1 and a box body arranged sequentially from top to bottom.

[0068] The box body includes a top plate 1-2, a side plate and a bottom plate 1-3 which are welded and fixed sequentially from top to bottom. The side panels include a first side panel 1-4, a second side panel 1-5, a third side panel and a fourth side panel 1-6 which are welded and fixed in sequence.

[0069] The lower end of the vertical plate 1-1 is welded and fixed to the top plate 1-2.

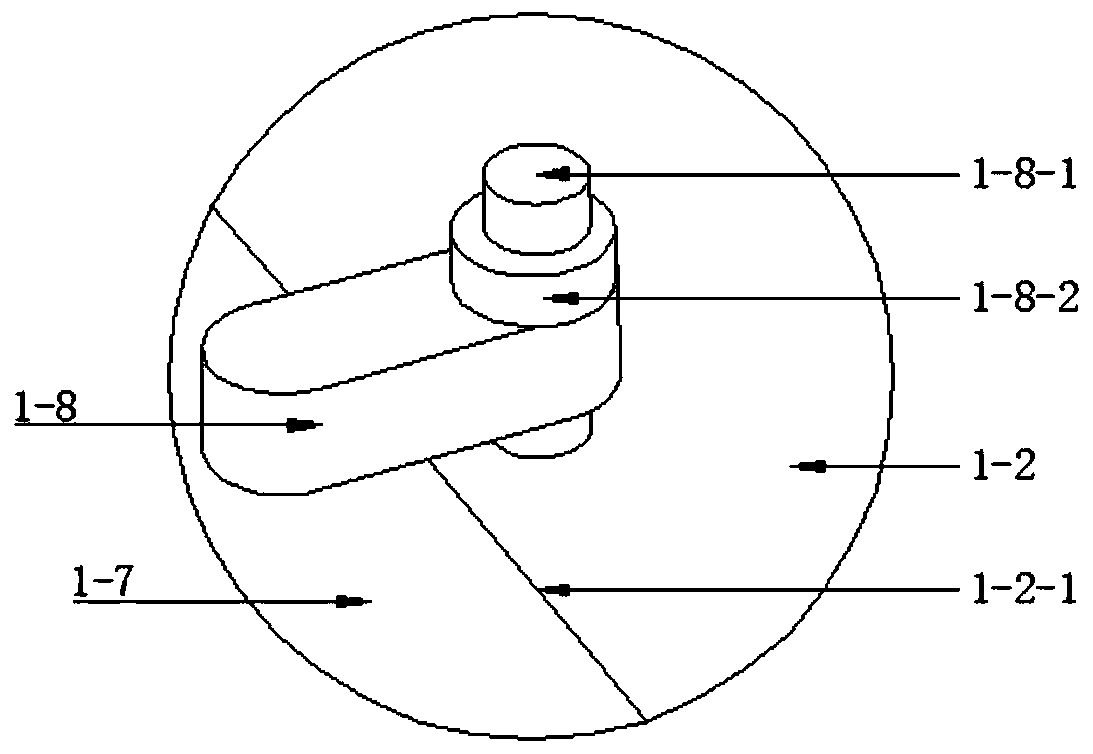

[0070] The top plate 1-2 is provided with a cover plate sliding hole 1-2-1 for communicating with the inner cavity of the box body, the cover plate sliding hole 1-2-1 cooperates with the cover plate 1-7, and the cover plate 1-7 is on the cover plate Slide left and right in the sliding hole 1-2-1.

[0071] For the convenie...

Embodiment 2

[0116] This embodiment 2 is the same as embodiment 1, the difference is that, as Figure 7 with Figure 8 Shown, in a kind of fruit pitting device of present embodiment 2.

[0117] The upper end surface of the fruit support plate 2-2 is provided with a fruit placement groove 2-2-1, and the groove bottom of the fruit placement groove 2-2-1 is provided with a first core removal hole 2-2-2. The support rod 2-1 is provided with a second denucleating hole 2-1-2. The cover plate 1-7 is provided with a third denucleating hole 1-7-6. The first denucleating hole 2-2-2, the second denucleating hole 2-1-2, the third denucleating hole 1-7-6, and the inner cavity of the box body are connected in sequence from top to bottom.

[0118] The lower end surface of the nuclear cleaning rod 4-2 is provided with a nuclear removal groove.

[0119] Take the removal of jujube pits as an example:

[0120] (1) Jujubes are placed in the fruit placement groove 2-2-1 on the upper end surface of the fru...

Embodiment 3

[0124] This embodiment 3 is the same as embodiment 2, the difference is that, as Figure 9 with Figure 10 As shown, in a kind of fruit pitting device of the present embodiment 3, it also includes a box-cleaning assembly.

[0125] The cleaning assembly includes a cleaning shovel 5-1 and a push rod 5-2.

[0126] First side plate 1-4 is provided with cleaning door opening 1-4-1, and cleaning door opening 1-4-1 is provided with cleaning door 1-4-2, and the left end of cleaning door 1-4-2 is connected with first side plate 1 -4 hinged. The upper end surface of the bottom plate 1-3 is inclined, and the end of the bottom plate 1-3 close to the third side plate is higher than the end of the bottom plate 1-3 close to the first side plate 1-4.

[0127] Open cleaning door 1-4-2 for convenience, the right end of cleaning door 1-4-2 is provided with cleaning door operating hole 1-4-3.

[0128] In order to prevent the cleaning door 1-4-2 from pushing into the inner cavity of the box bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com