Magnesium alloy casting ladle of continuous exchange of conductor and ceramic

A magnesium alloy and casting ladle technology, applied in foundry equipment, casting melt containers, manufacturing tools, etc., can solve the problems of easy cracking, reducing the internal contact surface of the casting ladle, difficult to take out, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

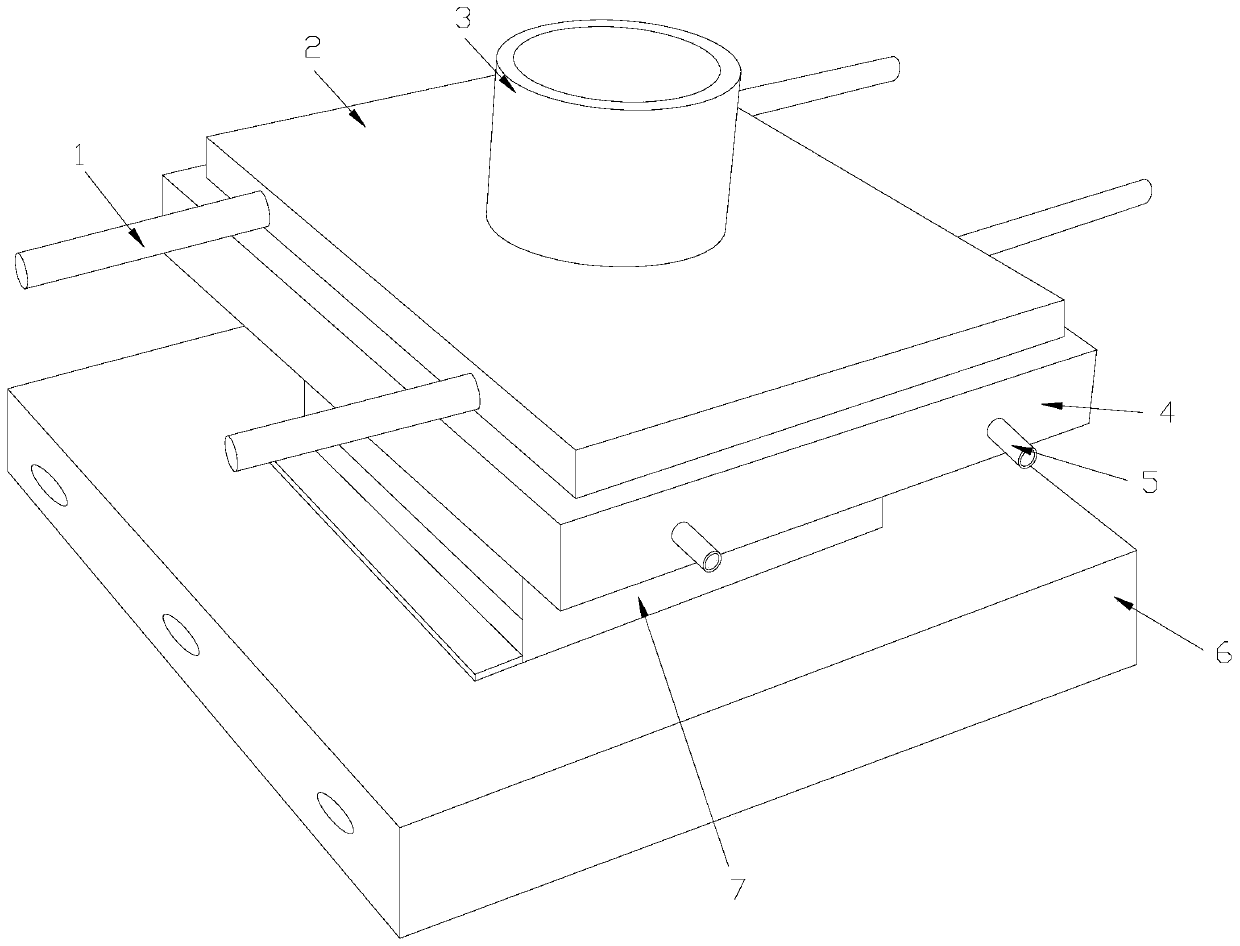

[0030] as attached figure 1 to attach Image 6 Shown:

[0031] The present invention provides a magnesium alloy casting casting ladle for continuous exchange of conductor ceramics, the structure of which includes a demoulding strut 1, a magnesium alloy casting upper sealing plate 2, a conductor ceramic continuous exchange device 3, a magnesium alloy casting lower sealing plate 4, The cooling pipe sleeve 5, the casting ladle base 6, and the seat plate 7, the demoulding strut 1 is fixedly connected to the magnesium alloy casting upper sealing plate 2 by means of electric welding, and the cooling pipe sleeve 5 is fixedly connected together by means of embedding Installed inside the magnesium alloy casting lower sealing plate 4, the top of the casting ladle base 6 is welded to the bottom of the seat plate 7, the bottom end of the conductor ceramic continuous exchange device 3 is fixedly connected to the top of the magnesium alloy casting upper sealing plate 2 Together.

[0032...

Embodiment 2

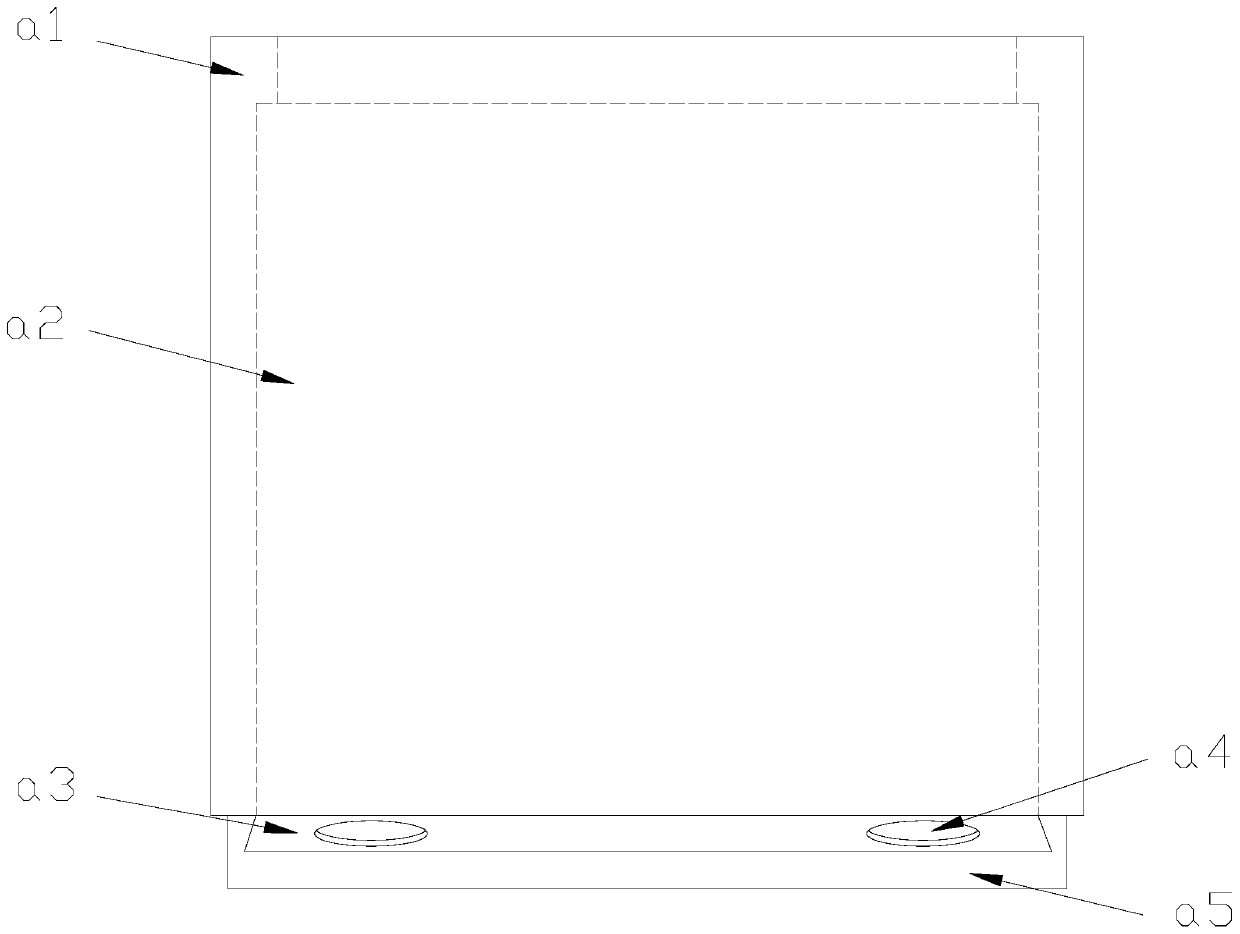

[0038] as attached Figure 7 to attach Figure 10 Shown:

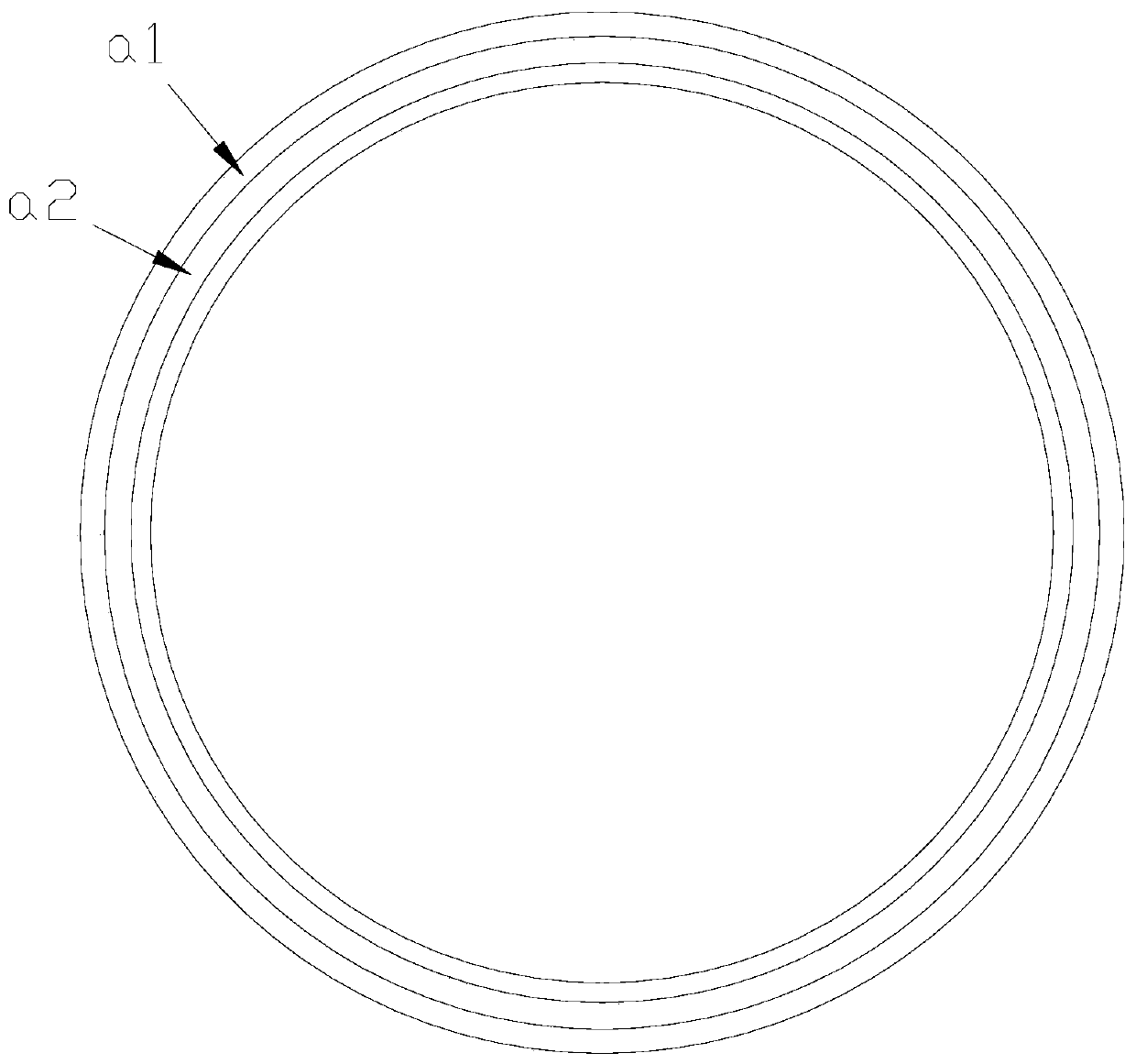

[0039] The invention provides a magnesium alloy casting ladle for continuous exchange of conductor ceramics. The elastic glue melting mechanism a221 includes an upper glue stick q1, a lower glue stick q2, and a lead q3. The upper glue stick q1 is embedded Installed inside the ceramic inner sleeve a223, the lower glue stick q2 is located directly below the upper glue stick q1 and is separated from the guide head q3 in the middle, and the guide head q3 is installed inside the ceramic inner sleeve a223 by embedding. The glue stick q1 is formed by punching the lower glue stick q2 through the guide head q3, and then can form a solid form of the glue stick after cooling, and will gradually soften and turn into a liquid state during the continuous action of heat.

[0040] Wherein, the guide head q3 includes a guide cover q31, a soft seal q32, and a flow opening q33. The flow opening q33 is arranged inside the guide cover q3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com