Printed circuit board stack

A printed circuit substrate and printed circuit technology, applied in the directions of printed circuit, printed circuit, stacking and separating printed circuit boards, etc., can solve the problem of not being able to fully guarantee the connection stability, etc., to improve the connection stability and achieve miniaturization. , the effect of using space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

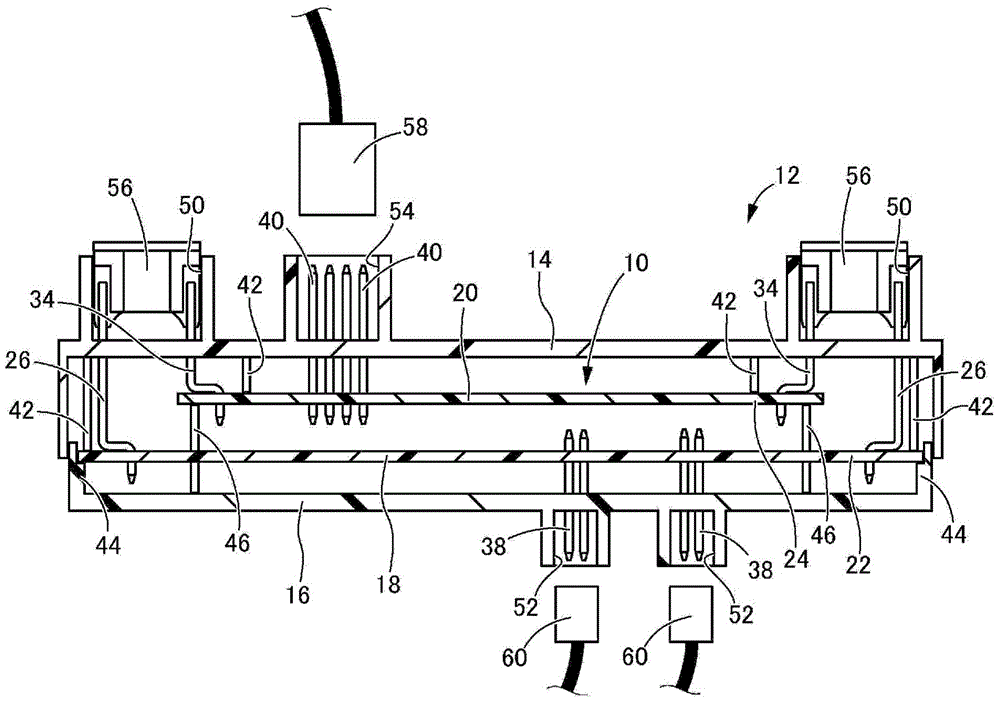

[0027] First, in figure 1 The electrical junction box 12 provided with the printed circuit board laminated body 10 which is 1st Embodiment of this invention is shown. The electrical junction box 12 has a structure in which the printed circuit board laminate 10 is accommodated between an upper case 14 and a lower case 16 formed of synthetic resin. In addition, in the following description, the upper side refers to the side that is the upper case 14 side. figure 1 The upper and lower refer to the side of the lower housing 16 as the figure 1 in the bottom.

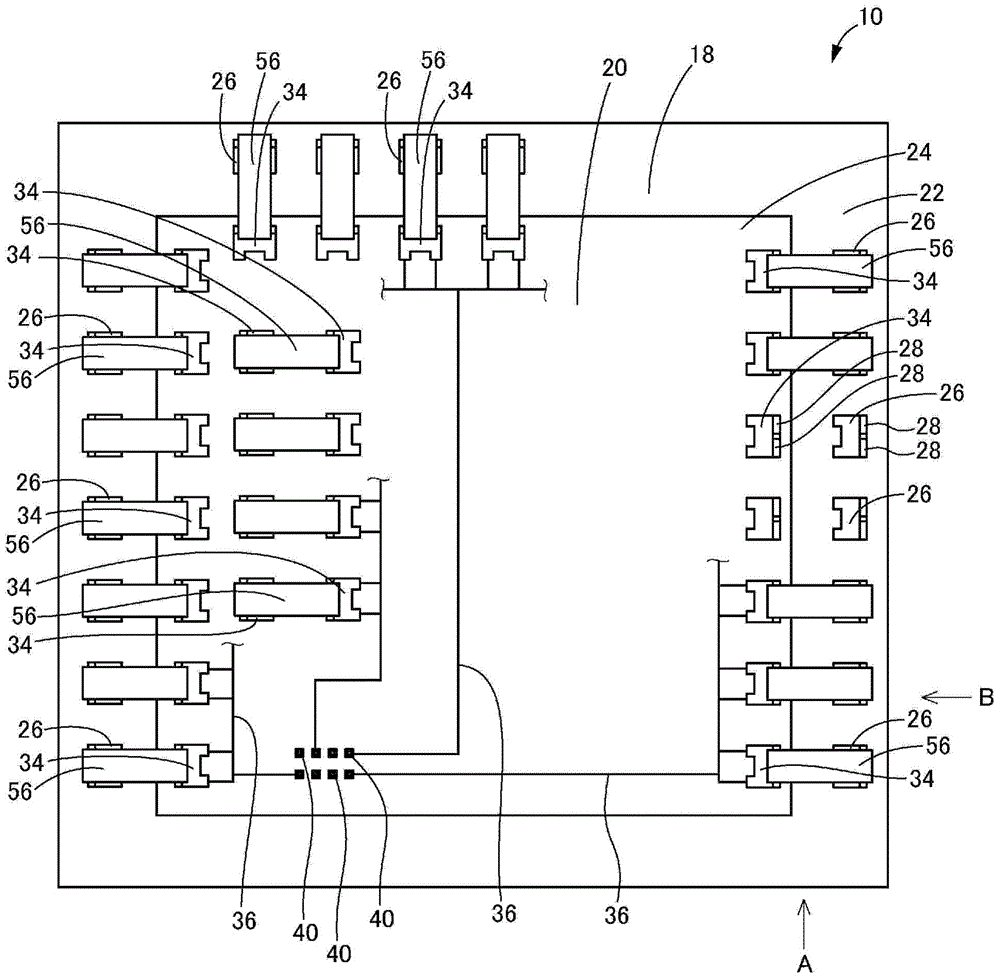

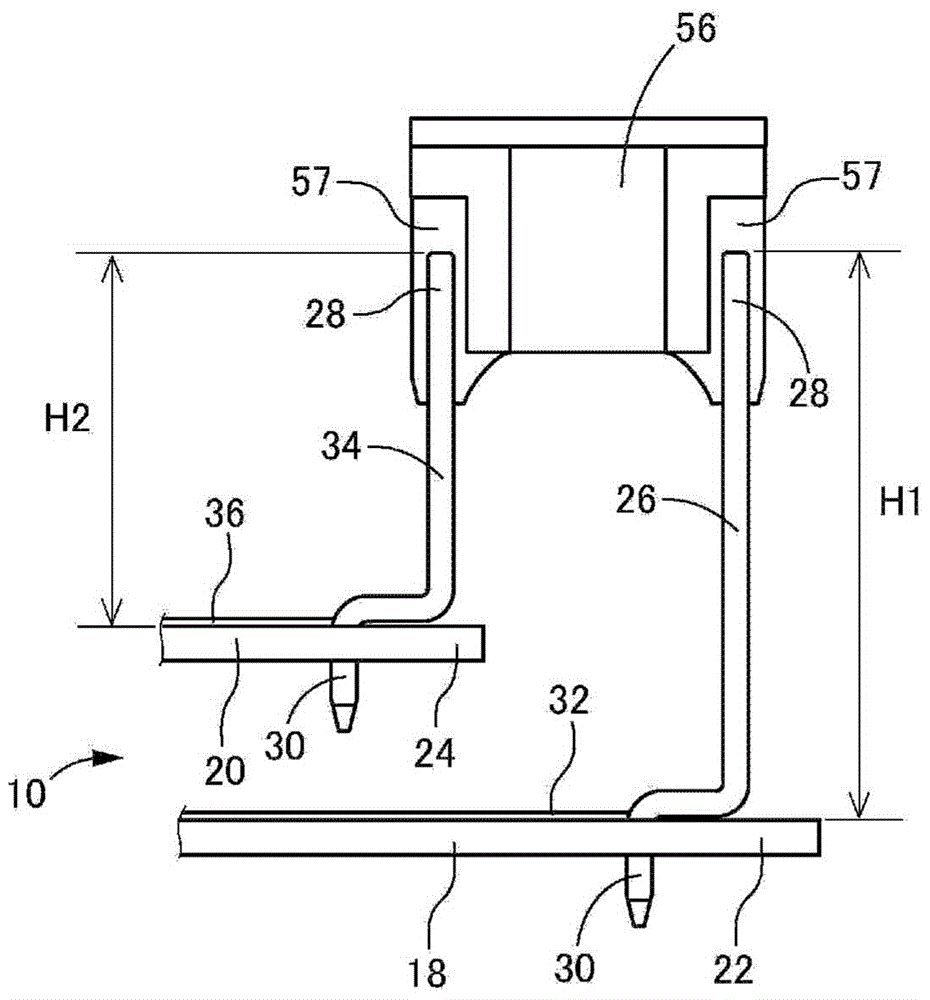

[0028] figure 2 The upper surface of the printed circuit board laminate 10 is shown, and in image 3 and Figure 4 The main part of the printed circuit board laminated body 10 is shown. In addition, in Figure 2 ~ Figure 4 In , for easy understanding, a fuse 56 to be described later is shown together. The pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com