Water purifier with automatic backwash function, and automatic backwash cleaning method thereof

A technology for backwashing and water purifiers, applied in chemical instruments and methods, multi-stage water treatment, water/sewage multi-stage treatment, etc., can solve the problems of filter element pollution, affecting filtration water quality, and increasing cleaning costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

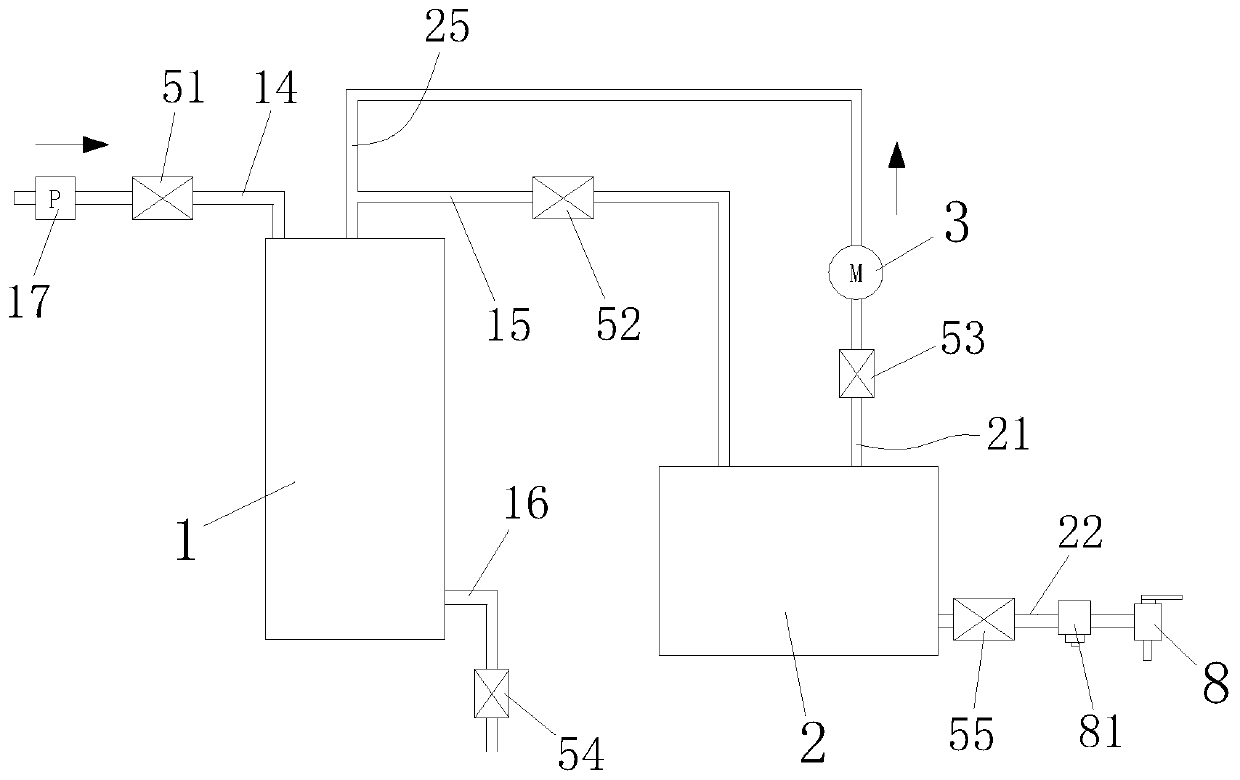

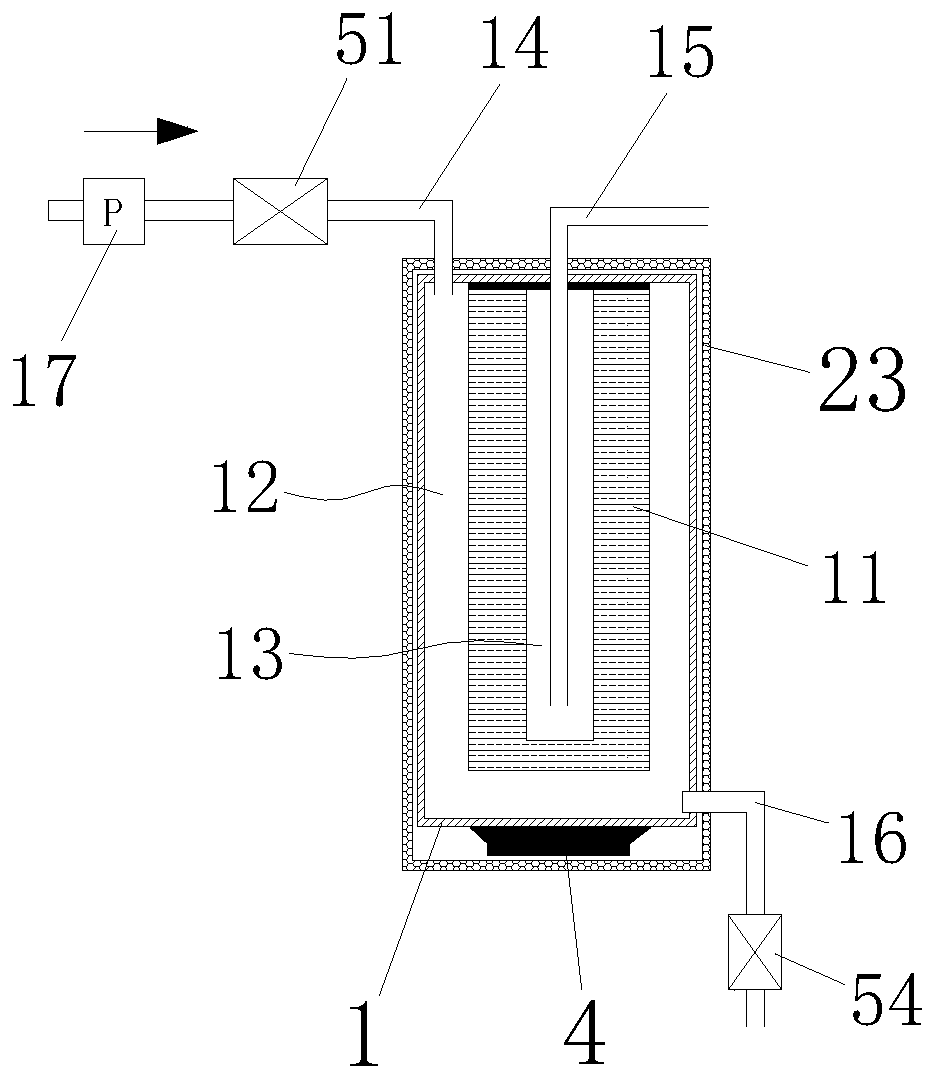

[0040] refer to Figure 1 to Figure 3 As shown, the present invention provides a water purifier with automatic backwashing, including: a primary filter device 1, a water storage tank 2, a booster pump 3, an ultrasonic transducer 4, a control device and a housing.

[0041] There is a first-level filter element 11 in the first-level filter device 1, and the first-level filter element 11 divides the inside of the first-level filter device 1 into a first-level first chamber 12 and a first-level second chamber 13, that is, the outer wall of the first-level filter element 11 and a first-level filter element. Between the inner sidewalls of the first-stage filtering device 1 is a first-stage first chamber 12 , and inside the first-stage filter element 11 is a first-stage second chamber 13 .

[0042] The primary filtering device 1 has a water inlet port communicating with the primary first chamber 12, a water outlet port communicating with the primary second chamber 13, and a drain por...

Embodiment 2

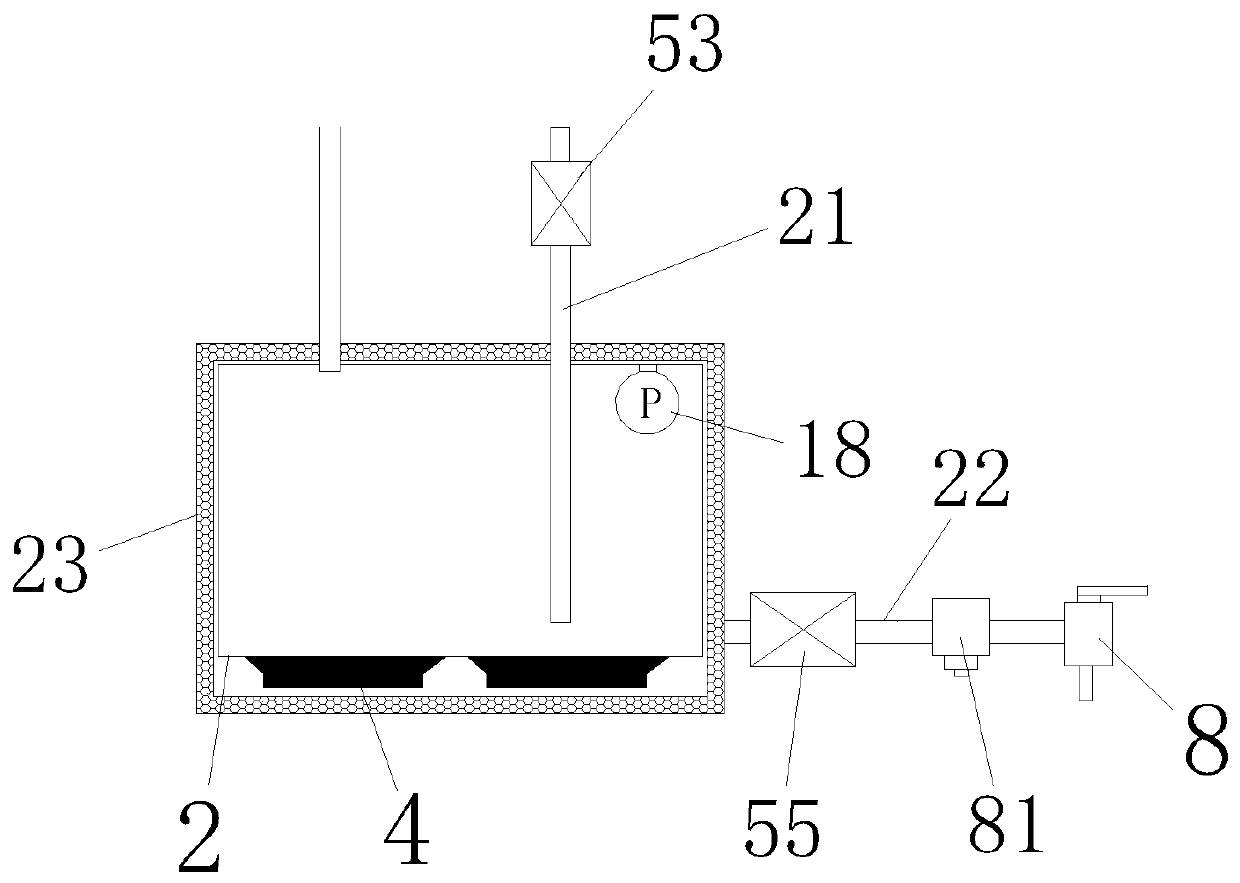

[0065] refer to image 3 and Figure 4 As shown, another embodiment of the present invention provides a water purifier with automatic backwashing, including: a primary filter device 1, a secondary filter device 6, a water storage tank 2, a booster pump 3, an ultrasonic transducer Device 4, control device and housing.

[0066] There is a first-level filter element 11 in the first-level filter device 1, and the first-level filter element 11 divides the inside of the first-level filter device 1 into a first-level first chamber 12 and a first-level second chamber 13, that is, the outer wall of the first-level filter element 11 and a first-level filter element. Between the inner sidewalls of the first-stage filtering device 1 is a first-stage first chamber 12 , and inside the first-stage filter element 11 is a first-stage second chamber 13 .

[0067] The secondary filter device 6 is similar in structure to the primary filter device 1. The secondary filter device 6 has a secondary...

Embodiment 3

[0093] refer to image 3 and Figure 5 As shown, another embodiment of the present invention provides a water purifier with automatic backwashing, including: a primary filter device 1, a secondary filter device 6, a tertiary filter device 7, a water storage tank 2, and a booster pump 3. Ultrasonic transducer 4. Control device and housing.

[0094] There is a first-level filter element 11 in the first-level filter device 1, and the first-level filter element 11 divides the inside of the first-level filter device 1 into a first-level first chamber 12 and a first-level second chamber 13, that is, the outer wall of the first-level filter element 11 and a first-level filter element. Between the inner sidewalls of the first-stage filtering device 1 is a first-stage first chamber 12 , and inside the first-stage filter element 11 is a first-stage second chamber 13 .

[0095] The secondary filter device 6 is similar in structure to the primary filter device 1. The secondary filter de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com