Three-way valve, compressor assembly, refrigerating device and control method of refrigerating device

A technology for a refrigeration device and a compressor is applied in the fields of refrigeration devices and their control, compressor components, and three-way valves, which can solve problems such as failure to return to normal, refrigeration system failure, and three-way valves that cannot work normally, so as to shorten the restart time. time, productivity, convenience and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

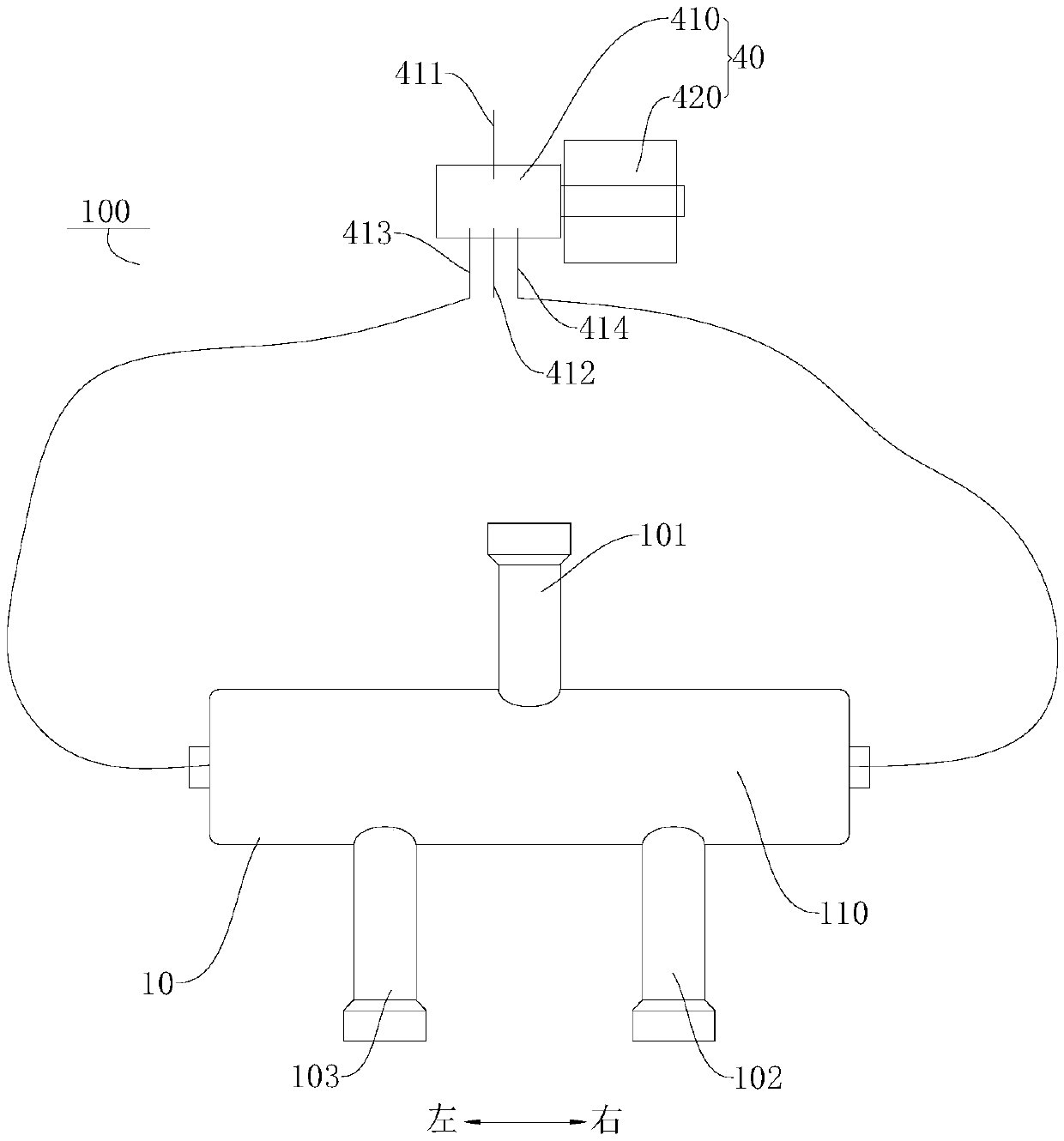

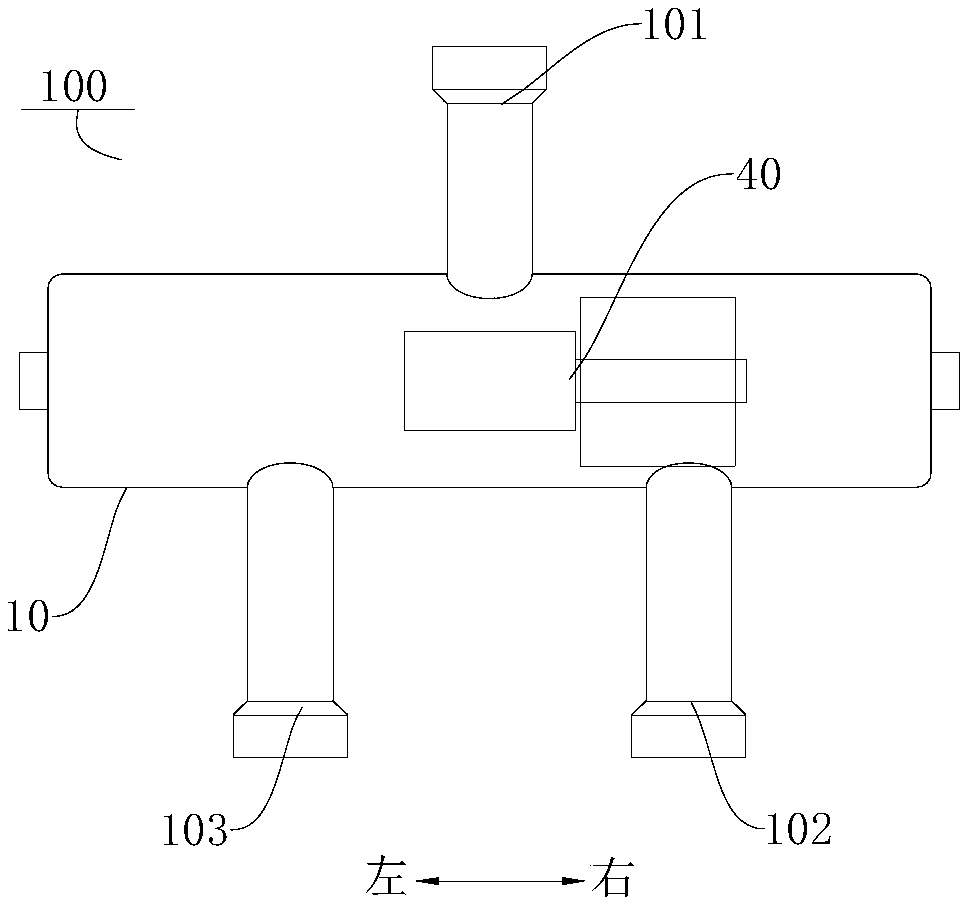

[0084] The refrigeration device includes: a compressor assembly, a first heat exchanger, a second heat exchanger, a throttling assembly, and the like.

[0085] Among them, such as Figure 9As shown, the compressor assembly includes: a compressor 50, a three-way valve 100 and an accumulator 60, etc., the compressor 50 is a rotary compressor 50, the compressor 50 includes a housing, a motor assembly and a compression assembly, and the housing defines In the accommodating space, the motor assembly and the compression assembly are located in the accommodating space, and the casing has an exhaust port 510 and an air return port 520 communicating with the inner space. The exhaust port 510 is provided with an exhaust pipe, and the accommodating space and the exhaust pipe together constitute the high-pressure side of the compressor assembly.

[0086] The liquid accumulator 60 is located outside the casing, and the liquid accumulator 60 communicates with the air return port 520 of the...

Embodiment 2

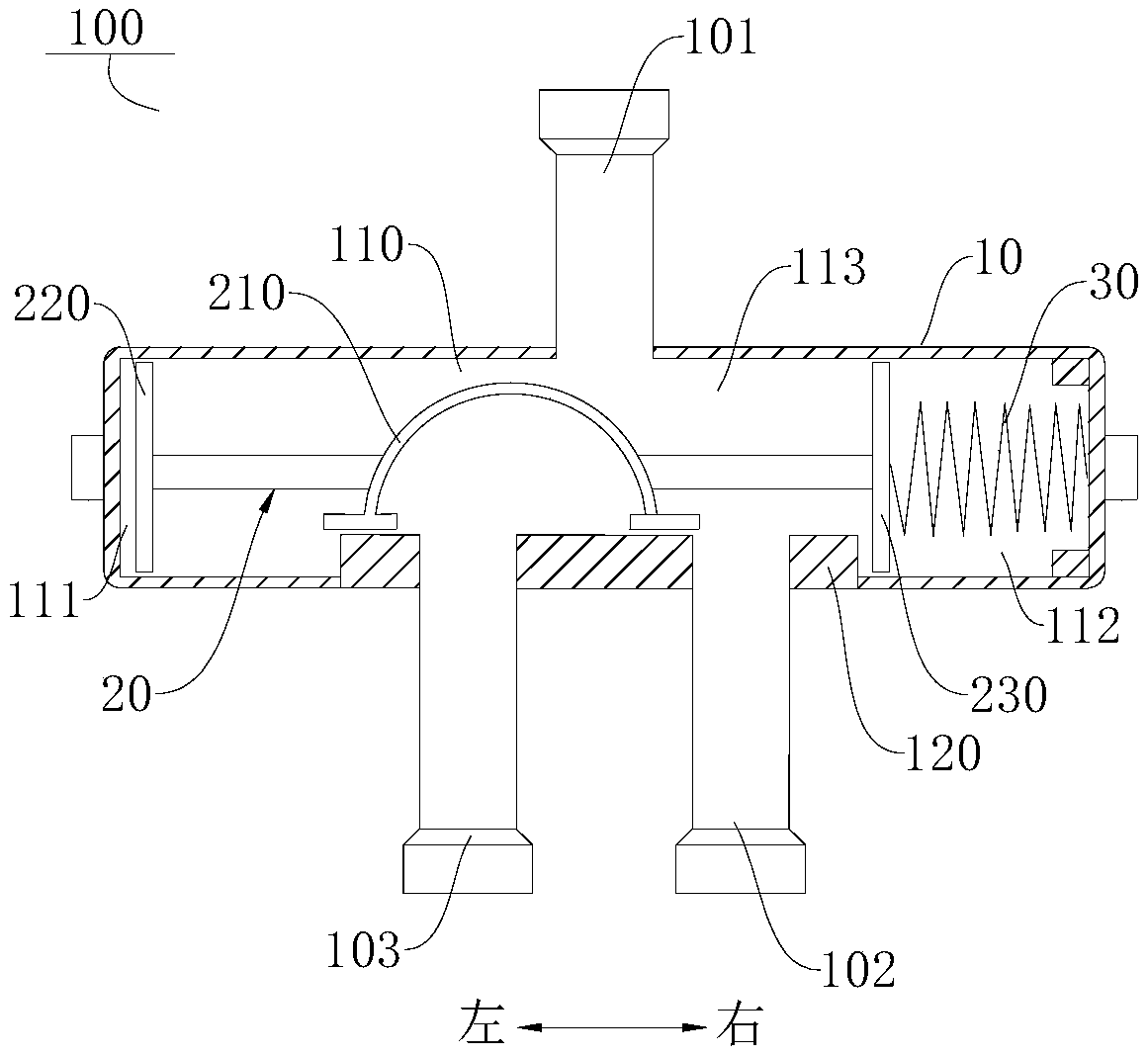

[0102] Such as Figure 5 and Figure 6 As shown, the difference from the first embodiment is that the elastic member 30 is disposed in the first chamber 111 . When there is no pressure difference or a small pressure difference between the two ends of the valve core 20, under the action of the elastic restoring force of the elastic member 30, the elastic member 30 can pull the valve core 20 to be in the first position.

Embodiment 3

[0104] Such as Figure 7 and Figure 8 As shown, the difference from Embodiment 1 is that in this embodiment, in this embodiment, the elastic member 30 includes a first elastic member 310 and a second elastic member 320, and the first elastic member 310 is located in the first chamber In 111 , the second elastic member 320 is disposed in the second chamber 112 . When there is no pressure difference or a small pressure difference between the two ends of the spool 20, under the action of the elastic restoring force of the first elastic member 310 and the second elastic member 320, the first elastic member 310 and the second elastic member 320 cooperate to normally The driving spool 20 moves toward the first position.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com