Method for manufacturing wireless passive flexible pressure sensor based on LC resonance

A pressure sensor, wireless passive technology, applied in the field of wireless passive flexible pressure sensor production, can solve the problems of high maintenance cost, low work efficiency, high energy consumption, and achieve the effects of long service life, simple structure and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] A method for manufacturing a wireless passive flexible pressure sensor based on LC resonance, comprising the steps of:

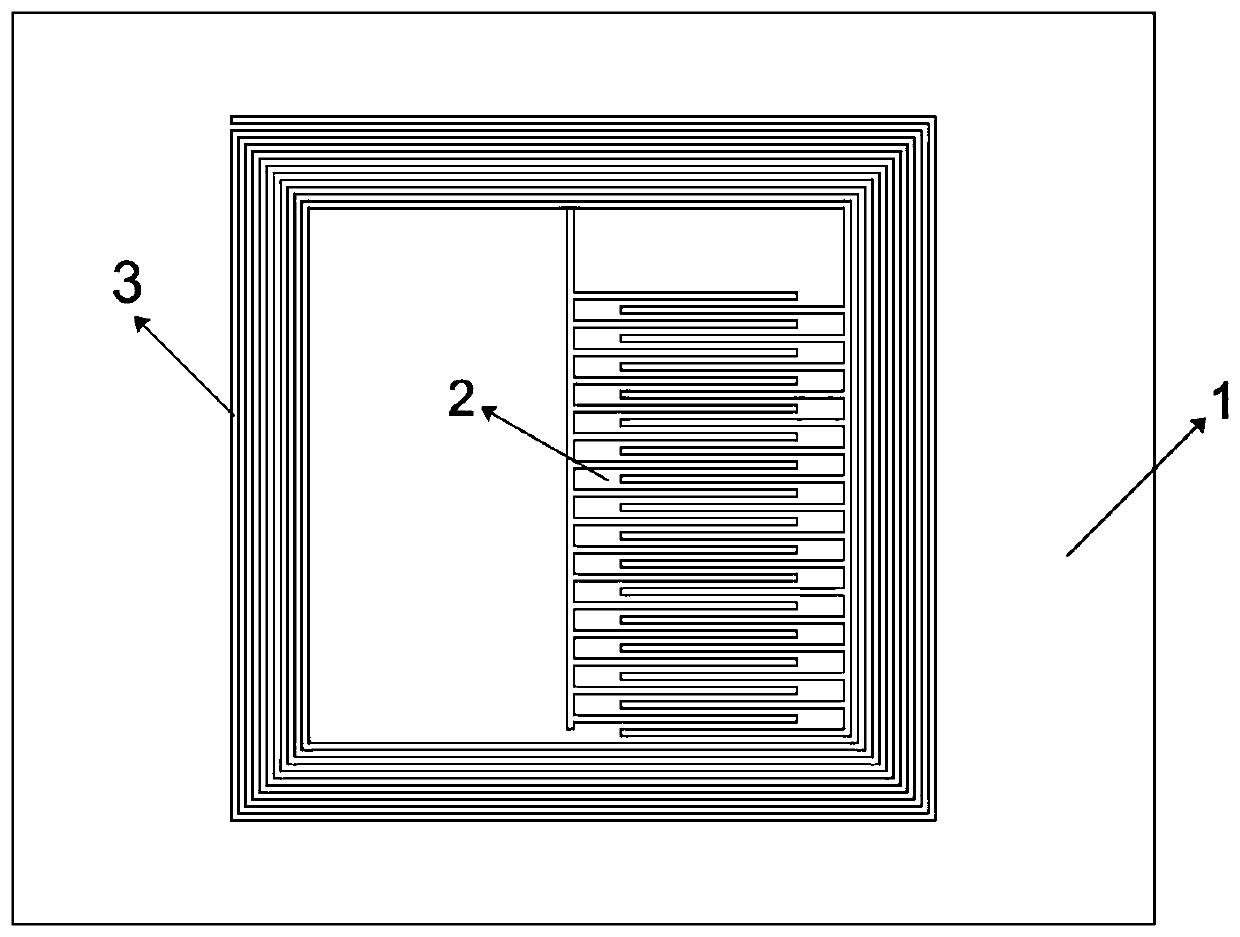

[0034] S1. Print the LC resonant circuit composed of the planar spiral inductor 2 and the planar interdigitated capacitor 3 on the flexible substrate 1; the structure of the planar spiral inductor and the planar interdigitated capacitor of the present invention is as follows figure 1 As shown, the method of screen printing is prepared with silver paste;

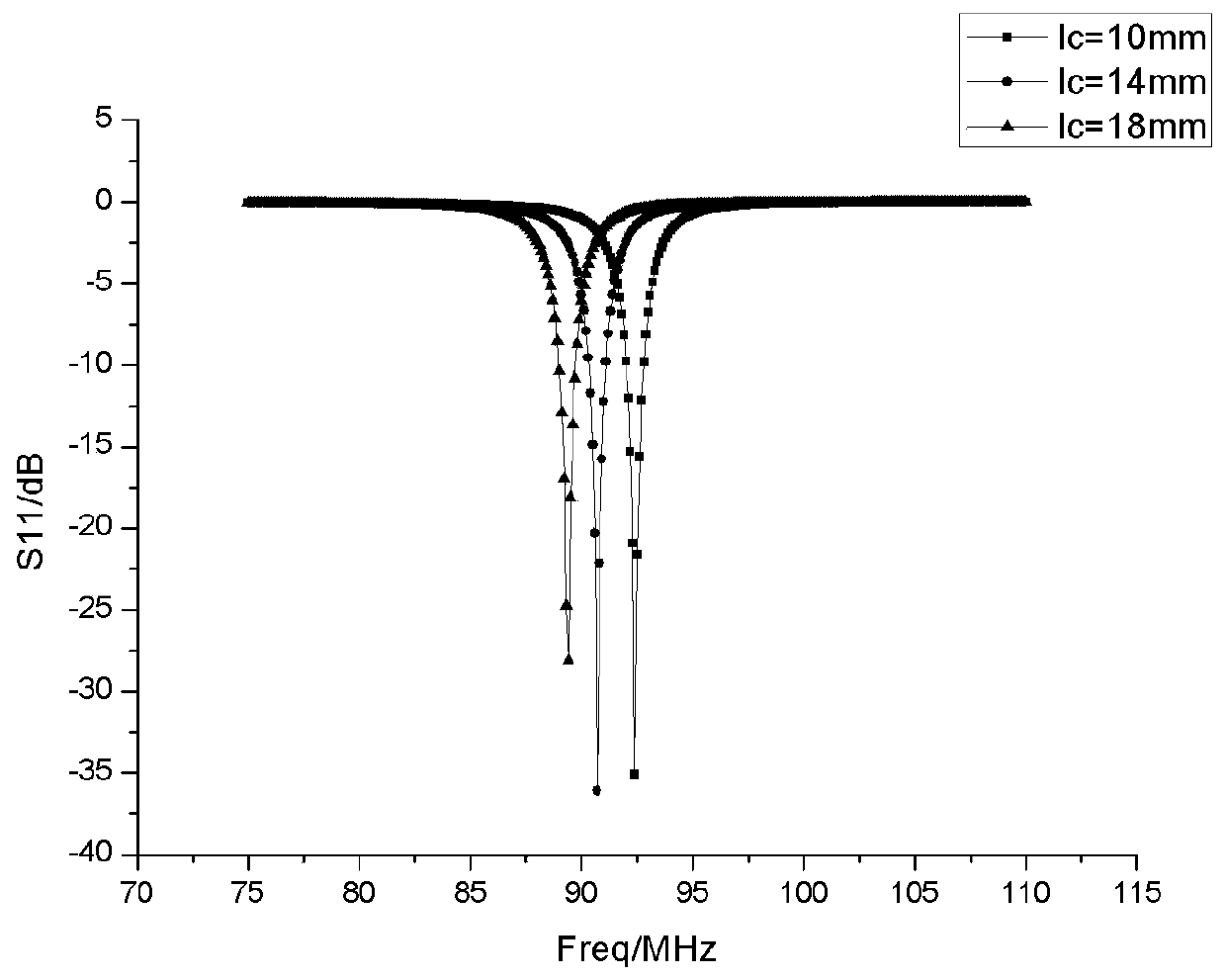

[0035] S2, coupled with the detection coil to generate a resonant frequency;

[0036] S3. When the pressure applied to the flexible substrate 1 changes, the capacitance of the flexible substrate 1 changes;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com