Subsoiler based on independent driving system and working method

An independent drive, deep loosening technology, applied in the fields of tillage equipment, agricultural machinery and equipment, application, etc., can solve the problems of complex hydraulic system, difficult maintenance, and inconvenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

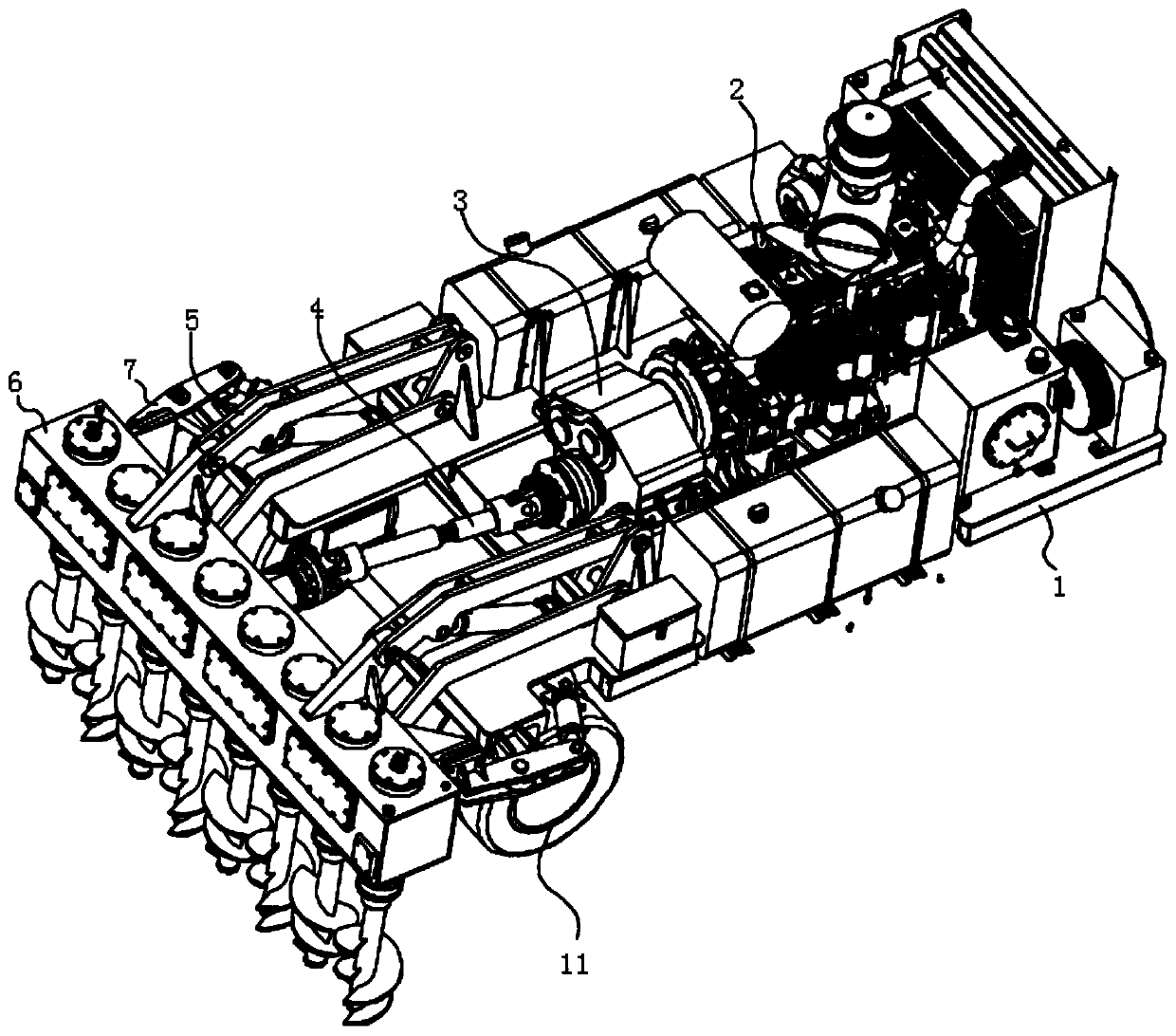

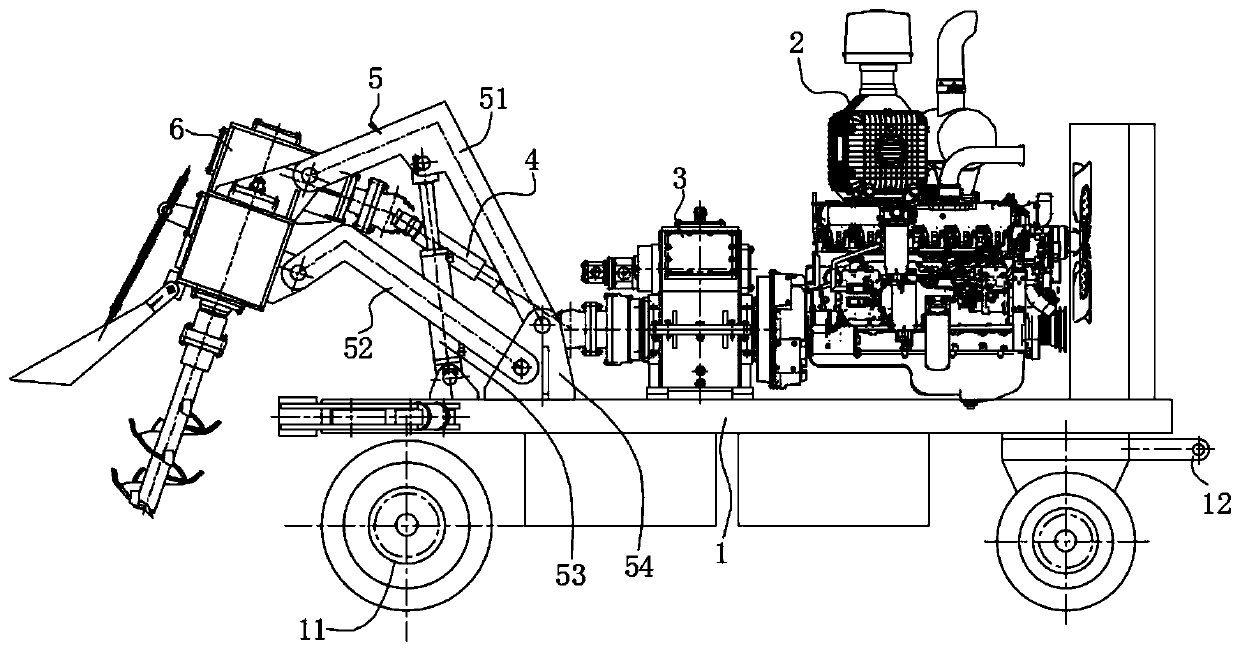

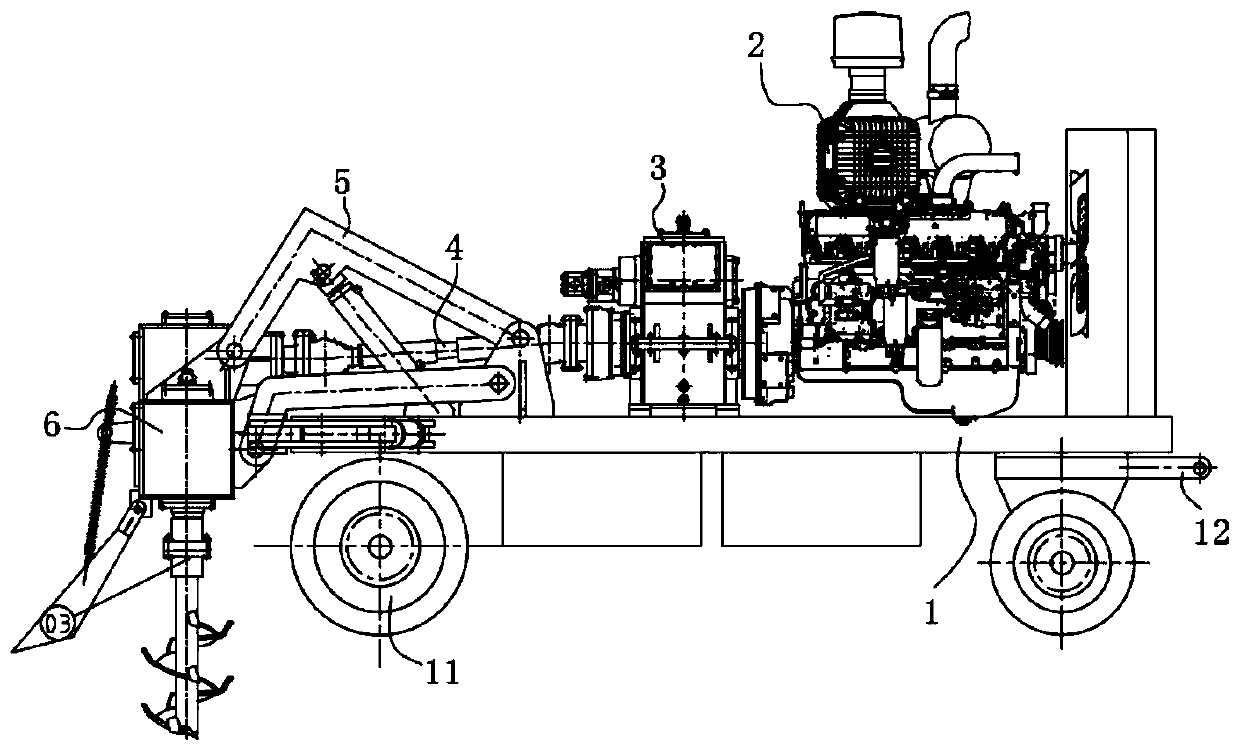

[0047] Such as Figure 1 to Figure 4 As shown, the subsoiler based on an independent drive system includes a frame 1 , a power unit 2 , a gearbox 3 , a coupling device 4 , a connecting device 5 , a subsoiler device 6 and a clamping and limiting device 7 .

[0048] At the bottom of the frame 1, a wheel 11 is installed through an axle, and the wheel 11 is a non-driven free wheel. A trailer frame 12 is provided at the front end of the vehicle frame 1, and the trailer frame 12 is used to be connected with traction equipment such as a tractor.

[0049] The power plant 2 is a diesel engine. The diesel engine is fixed on the frame 1.

[0050] The gearbox 3 is installed on the frame 1, and the output end of the power unit 2 is connected to the input end of the gearbox 3.

[0051] Such as Figure 5 to Figure 7 As shown, the gearbox 3 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com