Garbage classification all-in-one machine

A technology of garbage sorting and all-in-one machine, which is used in solid waste removal, chemical instruments and methods, transportation and packaging, etc., can solve problems such as poor sorting effect and complex structure, avoid manpower and material resources, improve accuracy, and improve reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

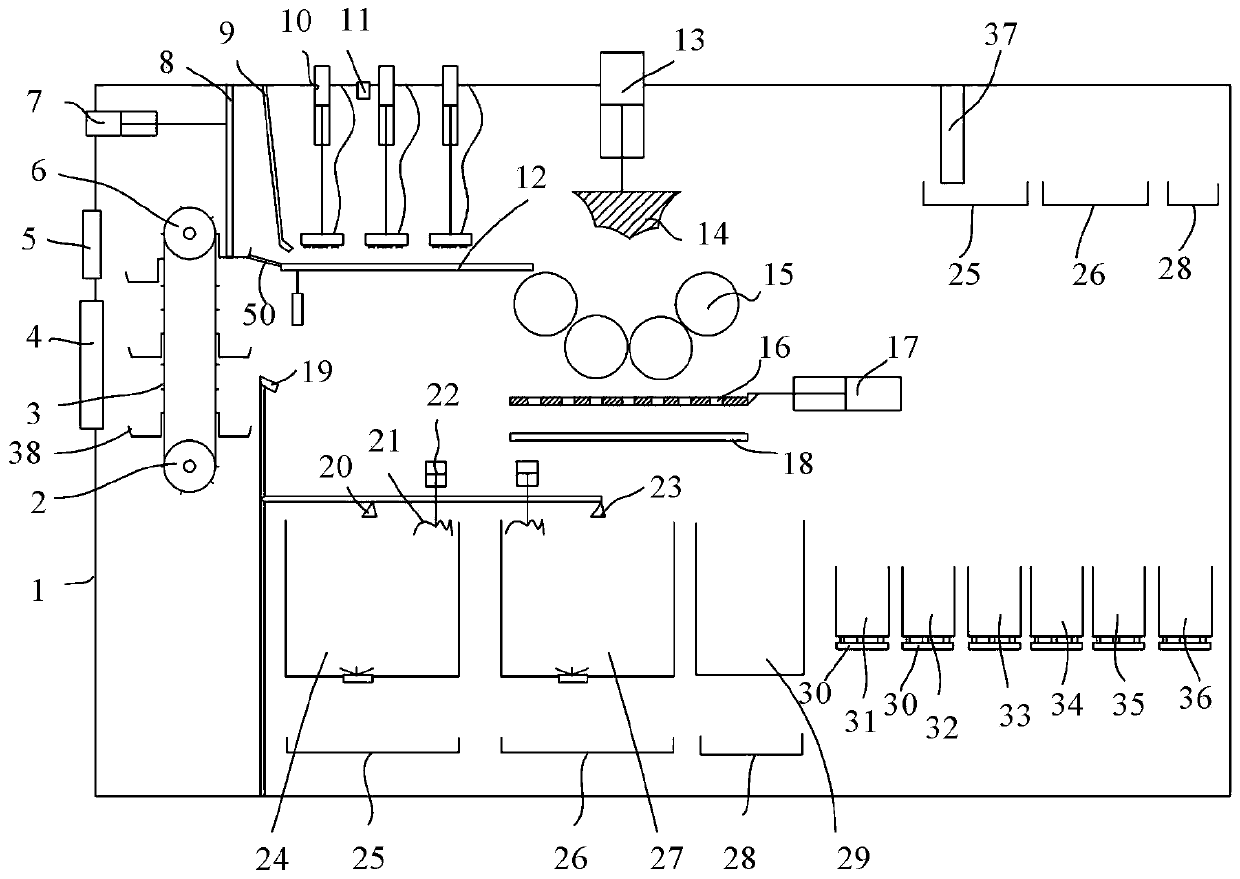

[0027] Such as figure 1 As shown, a garbage sorting integrated machine in this embodiment includes a chassis 1, a box conveying device, a telescopic suction cup assembly 10, an identification camera 11, a push plate cylinder 7, a garbage push plate 8, a garbage box 38, and a first shaker Plate 12, crushing device 15, second shaking plate 16, shaking cylinder 17, third shaking plate 18, first washing dryer 24, second washing dryer 27, drying dryer 29 and garbage sorting device; A garbage inlet 4 is opened on the side wall of the case 1, and a screen 5 is arranged directly above the garbage inlet 4; a box conveying device is arranged in the case 1 near the garbage inlet 4, and a garbage box 38 is hung on the box conveying device; The push plate cylinder 7 is fixed on the side wall of the case 1, and the end of the push plate cylinder 7 is vertically fixed with a trash push plate 8. The lower end of the trash push plate 8 is located in the trash box 38 on the box conveying device; ...

Embodiment 2

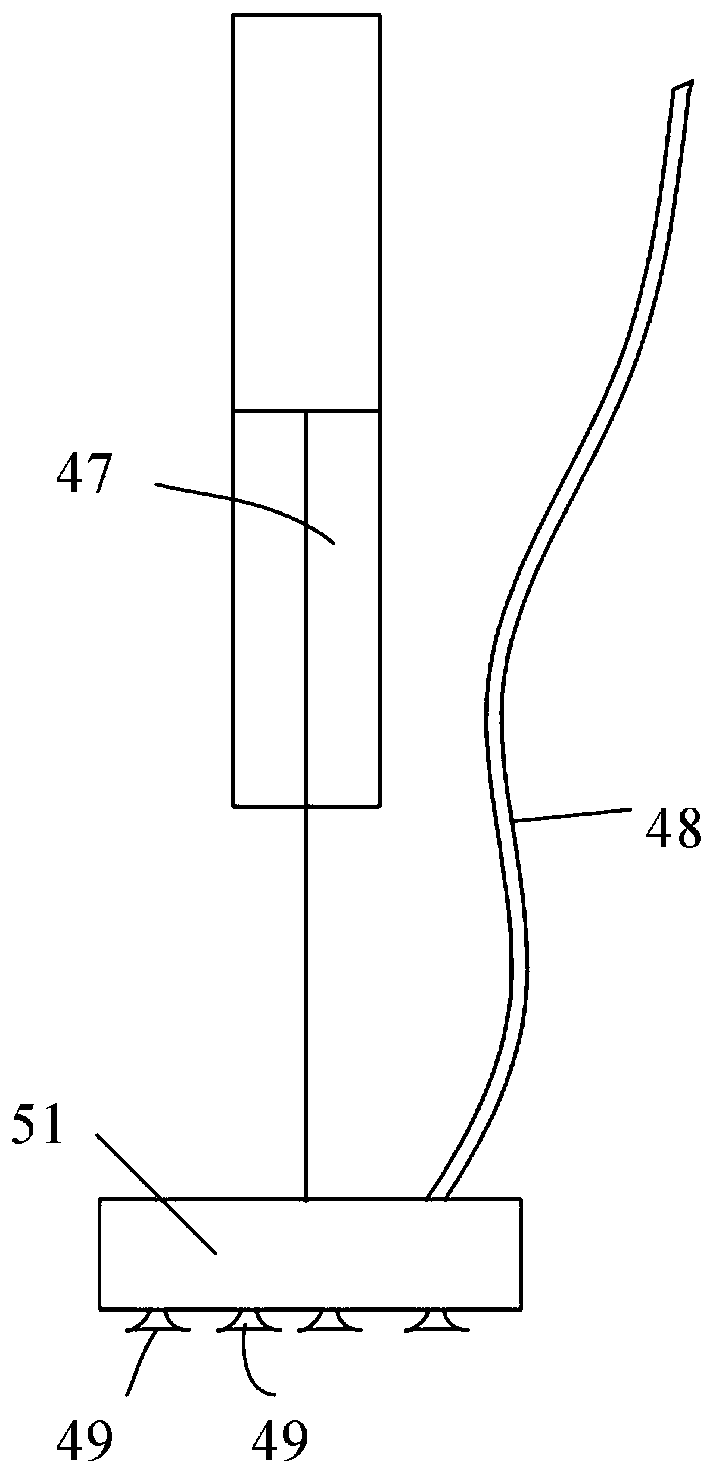

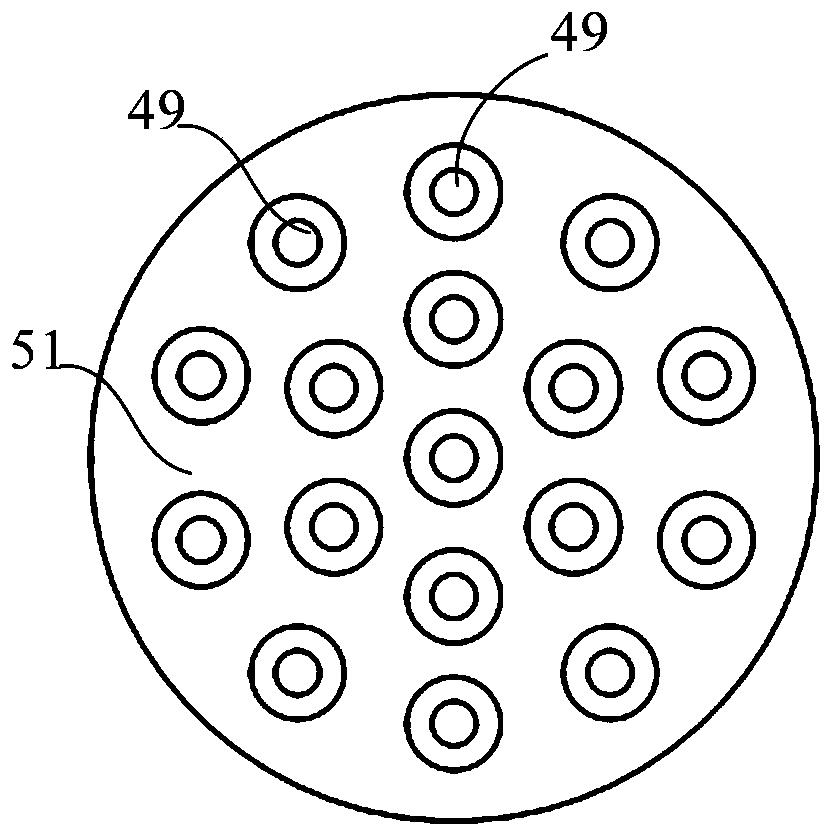

[0031] Such as Figure 1 to Figure 6 As shown, a garbage sorting integrated machine in this embodiment includes all the technical features in Embodiment 1. In addition, the box conveying device includes a conveying motor, a driving wheel 2, a transmission belt 3, a driven wheel 6 and a hanging wheel. A connecting plate 39, the driven wheel 6 is vertically arranged directly above the driving wheel 2, and the driving wheel 2 and the driven wheel 6 are connected by a transmission belt 3, and a plurality of hooking plates 39 are fixed at equal intervals on the outer side wall of the transmission belt 3. The plate 39 is used to hook the trash box 38, and the driving wheel 2 is in transmission connection with the output shaft of the conveying motor; the telescopic suction cup assembly 10 includes a suction cup cylinder 47, an air pipe 48, a suction cup body 51 and a plurality of suction heads 49, the cylinder body of the suction cup cylinder 47 Fixed on the inner wall of the upper en...

Embodiment 3

[0034] Such as Figure 1 to Figure 6 As shown, a garbage sorting integrated machine in this embodiment includes all the technical features in Embodiment 2. In addition, it also includes an extrusion cylinder 13 and an extrusion head 14. The cylinder body of the extrusion cylinder 13 is fixed On the inner wall of the upper end of the chassis 1, an extruding head 14 is fixed at the telescopic end of the extruding cylinder 13, and the extruding head 14 is directly above the four-axis shredder 42, and the extrusion head 14 is close to the four-axis shredder 42. One side is provided with a curved surface that matches the outer contour of the gear on the processing side of the four-axis shredder 42; it also includes a flushing pipe 9 and a baffle 50. The flushing pipe 9 is arranged between the garbage push plate 8 and the telescopic suction cup assembly 10 to flush The outlet of the tube 9 is directly facing the first shaking plate 12, and a baffle 50 is provided on the lower side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com