Tobacco leaf subdivision device and method based on nicotine content

A tobacco leaf and content technology, applied in the direction of tobacco, tobacco preparation, application, etc., can solve the problems that cannot meet the needs of industrialization and process production, and achieve the effects of fast classification, reduced labor input, and improved uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

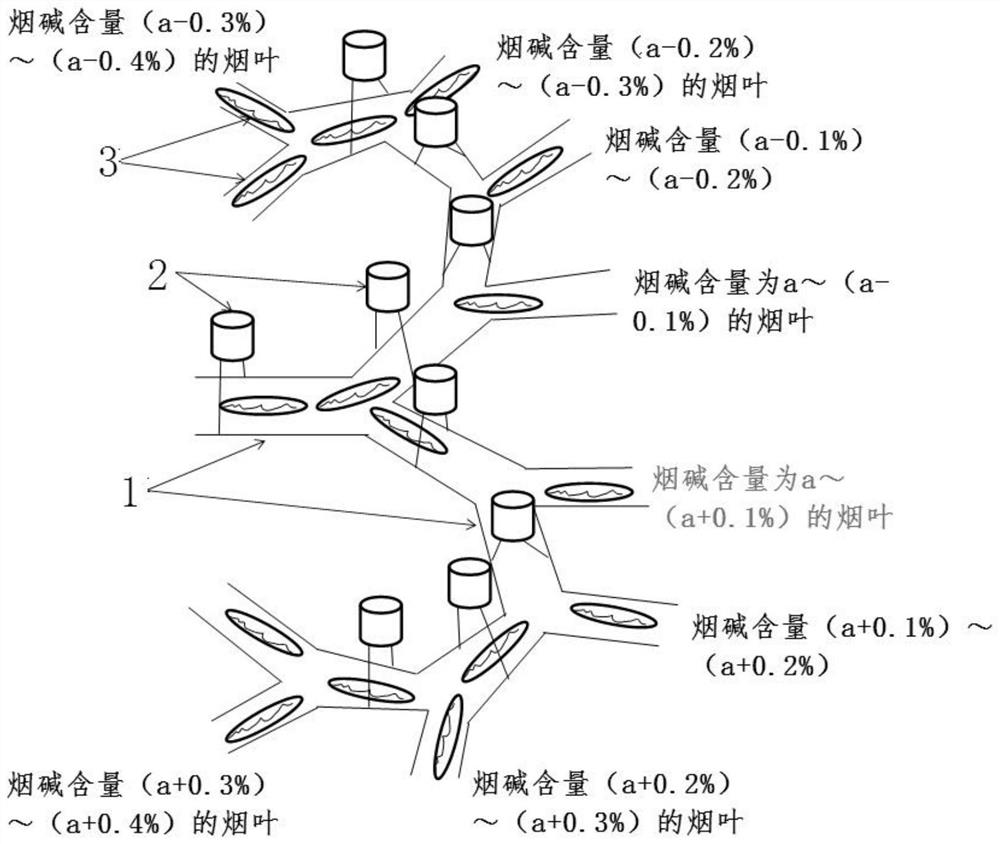

[0039] Such as Figure 1-3 As shown, this embodiment provides a tobacco leaf subdivision device based on nicotine content, including a conveyor belt module, the conveyor belt module includes a plurality of conveyor belts 1, and the multiple conveyor belts 1 form a plurality of bifurcated structures arranged in sequence , each of the bifurcated structures includes three sections of conveyor belts 1 arranged in a Y shape; the front end of each bifurcated structure at the bifurcated position is provided with a detection device 2 and a diverter, the The detection device 2 is used to detect the nicotine content of the tobacco leaves 3, and the diverter is used to control the conveying direction of the tobacco leaves 3; the forked structure at the front end is used to connect the leaf laying platform.

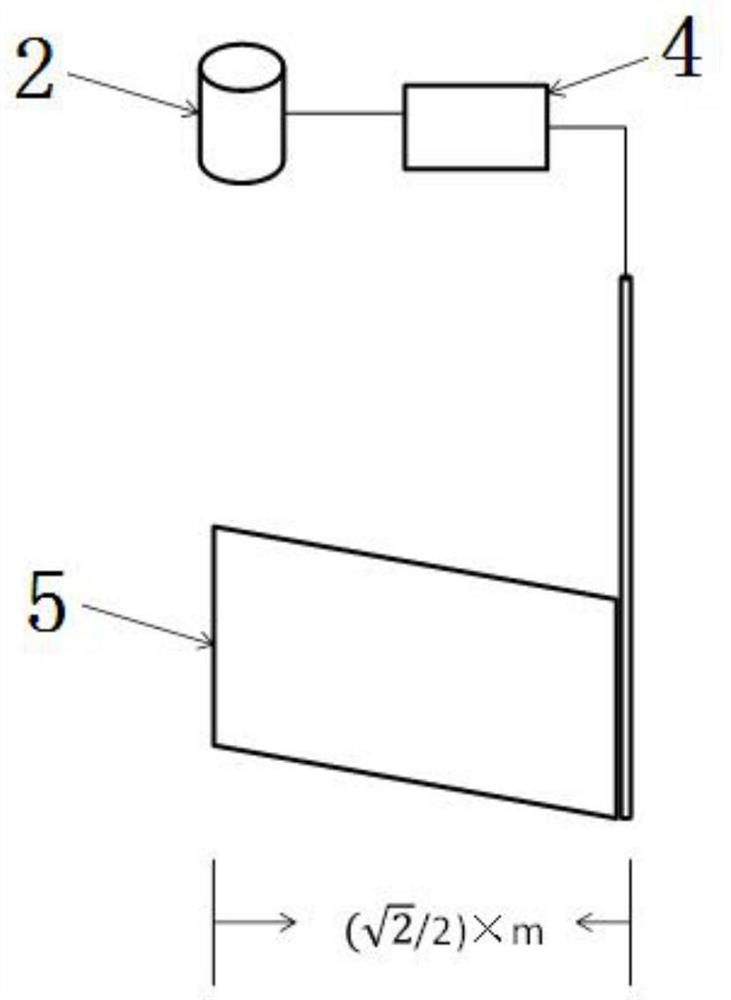

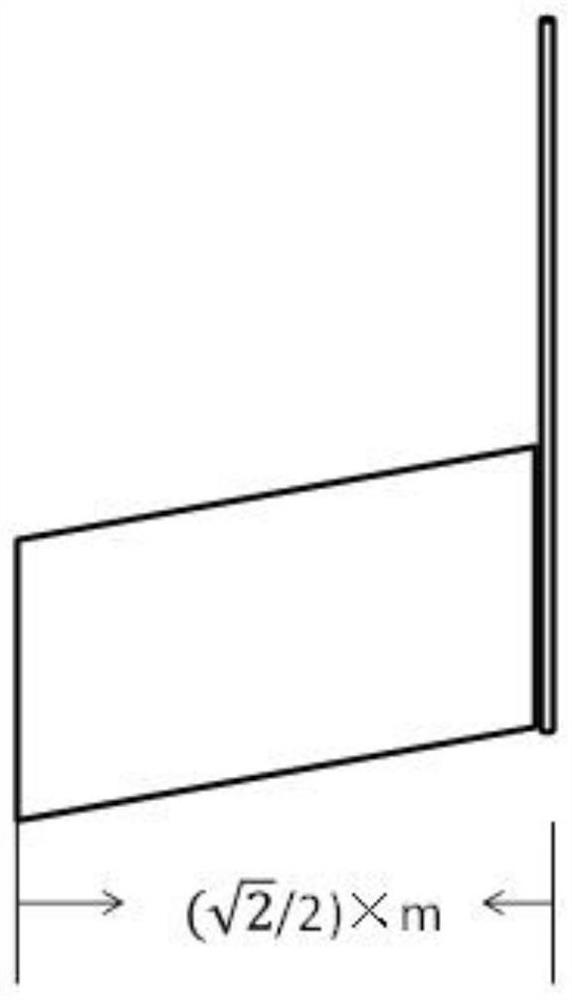

[0040] preferred, such as Figure 2-3 As shown, the diverter includes a turning baffle 5 and a controller 4, the controller 4 is connected with the turning baffle 5 and the detectio...

Embodiment 2

[0053] This embodiment is an improvement made on the basis of Embodiment 1. The improvement is that: in this embodiment, in steps 2) and 3), a is 0.1%, and n is 10. In this embodiment The tobacco leaf 3 subdivision method based on nicotine content comprises the following steps:

[0054] 1) Before threshing, set the most suitable nicotine content value (represented by a) according to the cigarette formula, tobacco leaf production area, tobacco leaf position and other factors;

[0055] 2) Disassemble the cigarette pack, and after heating and humidifying, make the tobacco leaves 3 basically reach the water content suitable for processing (15-17%); then disperse the tobacco leaves 3 on the leaf laying table; Crawler 1 advances under the effect of the frictional force of transmission crawler 1; a near-infrared (infrared) spectrometer is set above each bifurcation position of transmission crawler 1 to detect the nicotine content of tobacco leaf 3 (instant nicotine content), followe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com