Seamless steel pipe cold diameter expanding equipment and process

A technology of seamless steel pipe and equipment, which is applied in the field of seamless steel pipe cold expansion equipment and its process, can solve the problems of unsatisfactory expansion effect of seamless steel pipe, unsuitable for small and medium-sized enterprises, high equipment cost, etc., and achieves equipment structure. Simplicity, low equipment cost, and the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

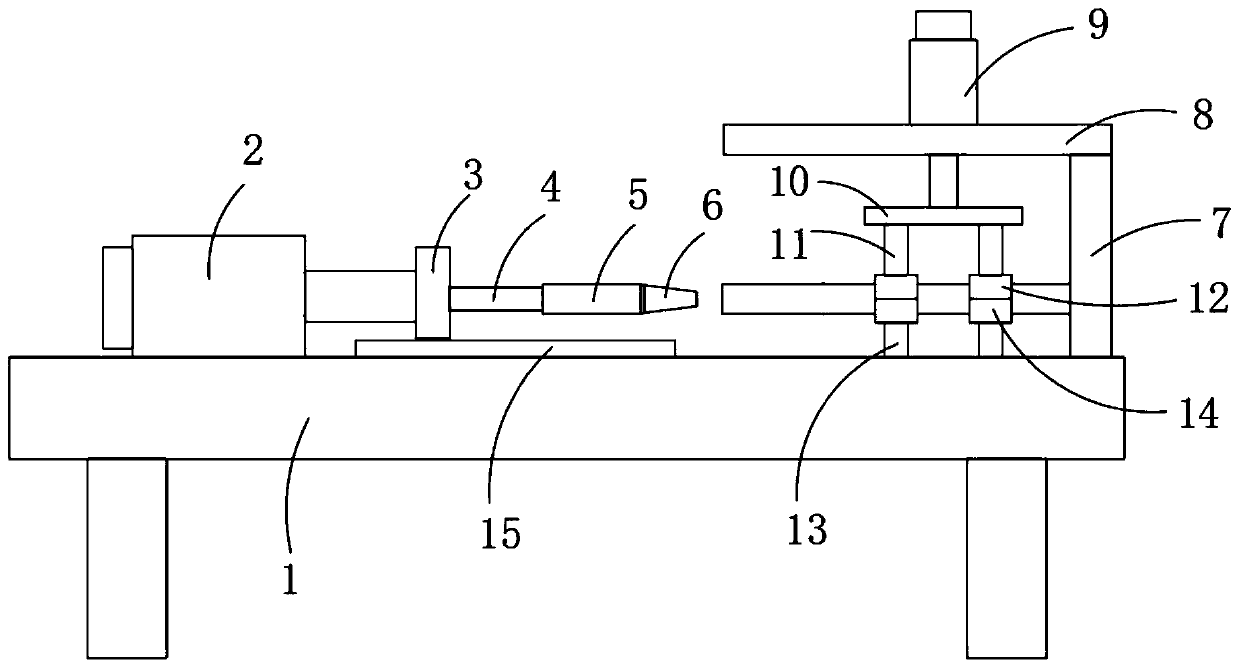

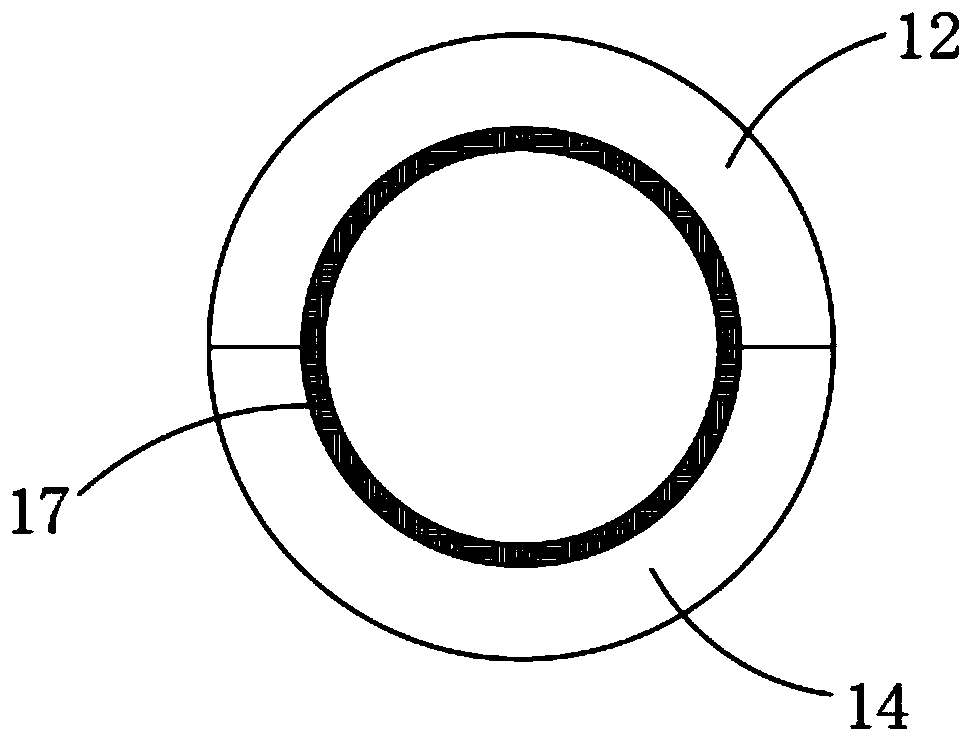

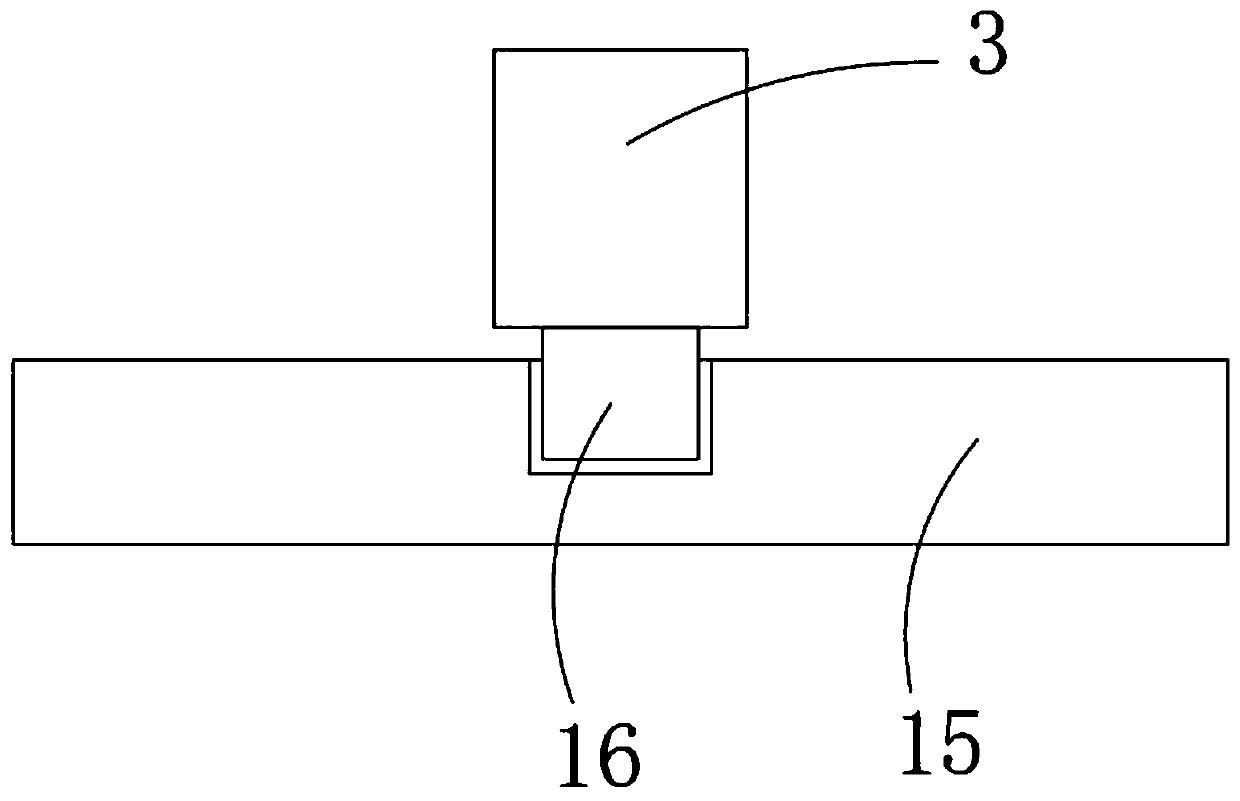

[0027] Such as Figure 1-3 As shown, the embodiment of the present invention provides a cold expansion equipment for seamless steel pipes, including a workbench 1, a first hydraulic cylinder 2 is fixedly installed on the upper surface of the workbench 1, and a first hydraulic cylinder 2 is fixedly installed on the output end of the first hydraulic cylinder 2. A mounting plate 3, the side of the first mounting plate 3 away from the output end of the first hydraulic cylinder 2 is fixedly installed with a threaded rod 4, and the end of the threaded rod 4 away from the first mounting plate 3 is threadedly connected with a pipe expansion die 5, and the pipe expansion die 5 One end away from the threaded rod 4 is fixedly connected with a reducing head 6, wherein the diameter of the reducing head 6 is smaller than the diameter of the pipe expansion die 5, and the upper surface of the workbench 1 is fixedly installed on the side away from the first hydraulic cylinder 2. Frame 7, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com