A column equipment for safe and stable machining

A technology of mechanical processing and columns, which is applied in the direction of metal processing equipment, metal processing machine parts, manufacturing tools, etc., can solve the problems of low work efficiency and cumbersome steps, so as to improve stability, flexibility, practicability and The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

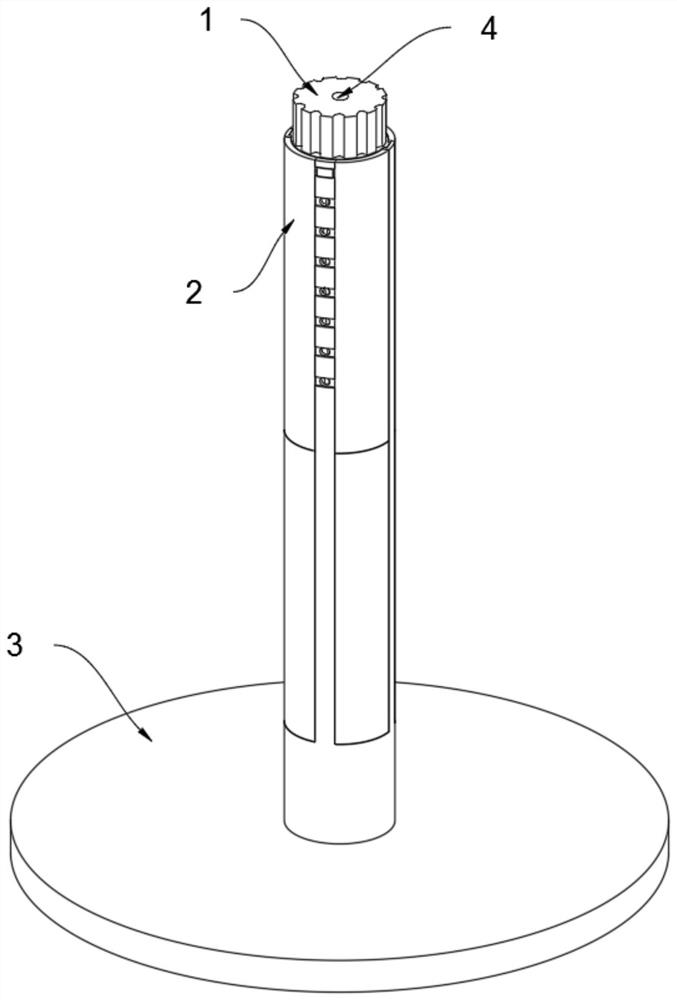

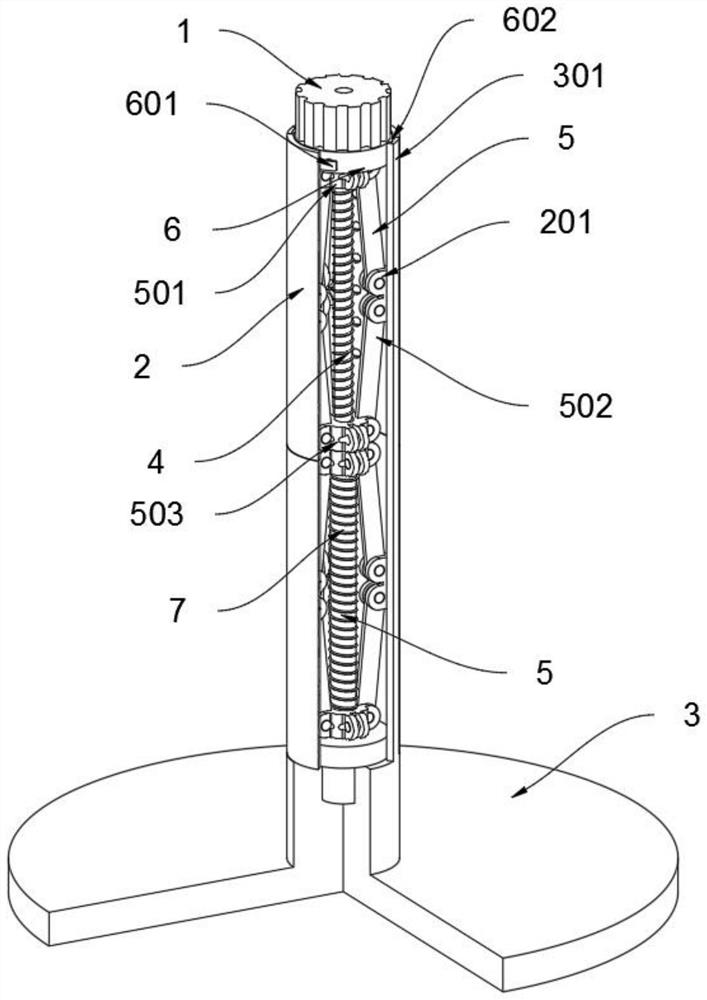

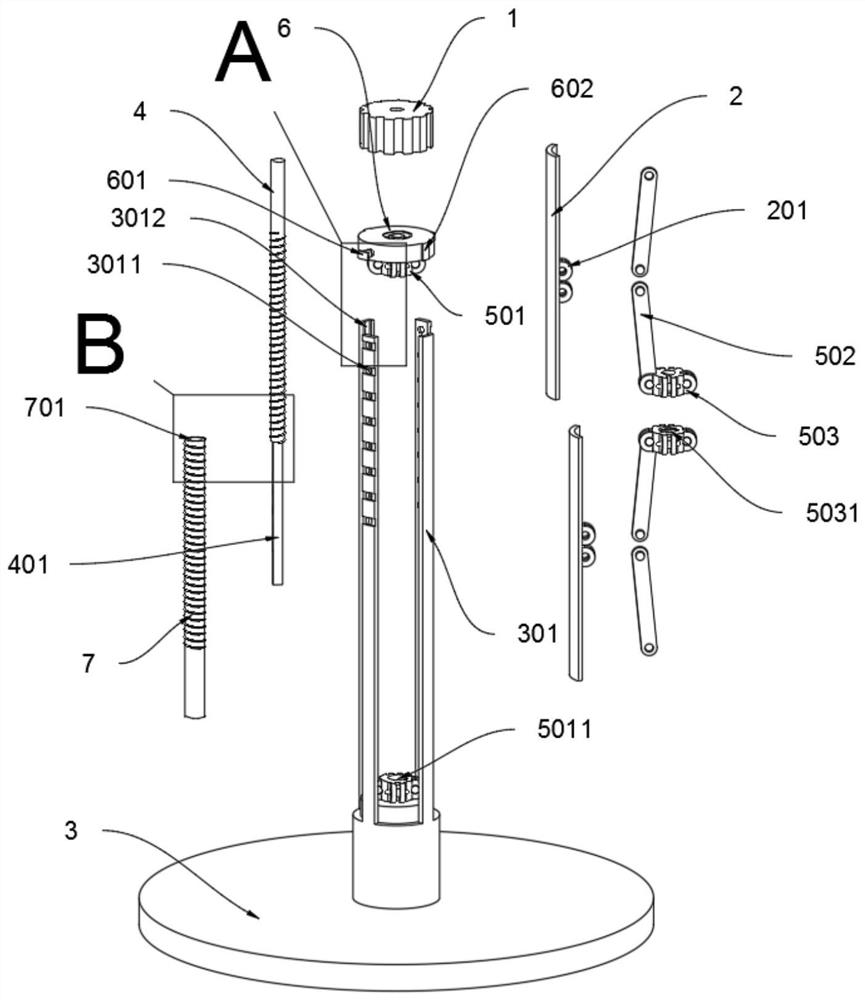

[0035] as attached figure 1 to attach Figure 8 Shown:

[0036] The present invention provides a column equipment for safe and stable machining, including an adjustment knob 1, a column piece 2 and a base 3; the middle part of the adjustment knob 1 is fixedly connected to the top of the synchronization rod a4; the connecting piece 201 in the middle of the column piece 2 is flexibly connected to the support One end of the two transmission rods 502 of the rod mechanism 5, and the connecting piece 201 is fixedly connected to the middle part of the inner side of the column piece 2; a positioning piece 6 is fixedly connected to the bottom of the base 3, and the base 3 is screwed and fixed on the work surface; The top of the base 3 is provided with four fixed rods 301, and the fixed rods 301 are arc-shaped, and the fixed rods 301 and the four column sheets 2 form a cylinder, as attached figure 1 And attached figure 2 As shown, this design enables the device to be used as a colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com