A slicer for garlic food processing

A food processing and slicer technology, applied in metal processing and other directions, can solve the problems of fixed positioning of garlic cloves and inconsistent cross sections, and achieve the effect of precise slicing work, convenient positioning, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

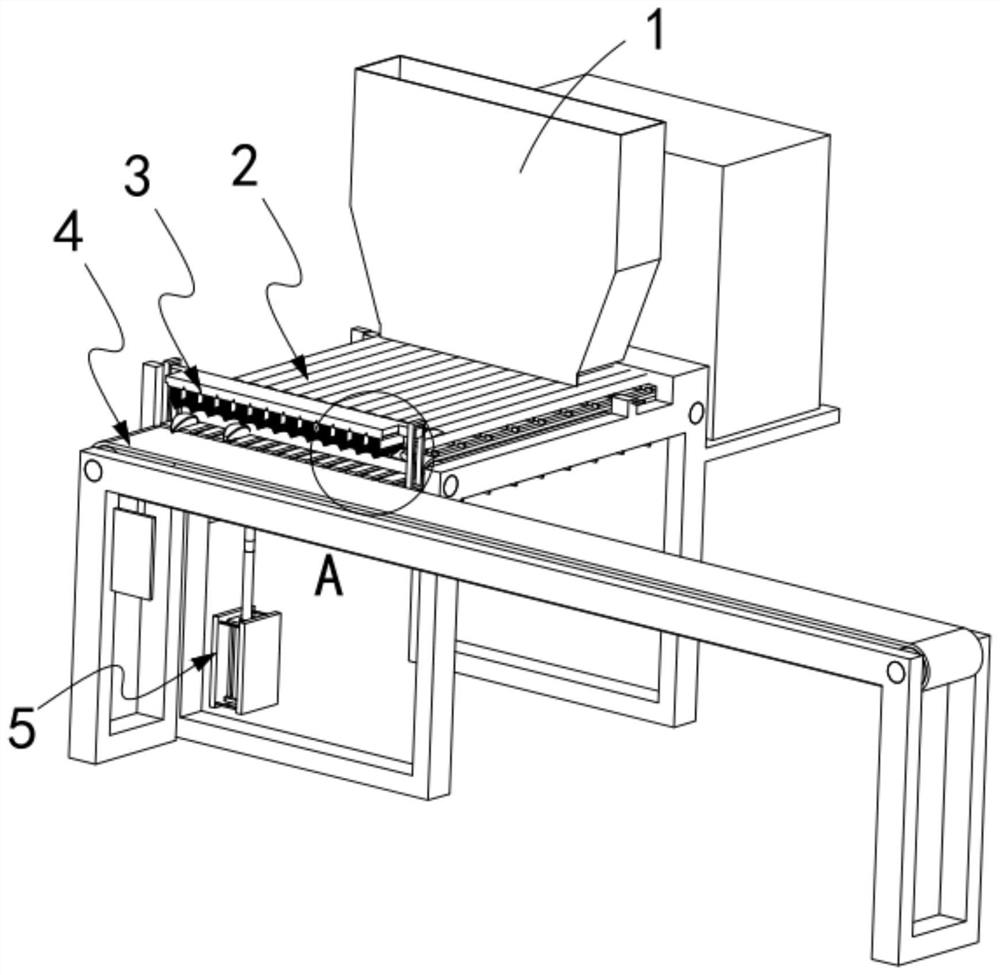

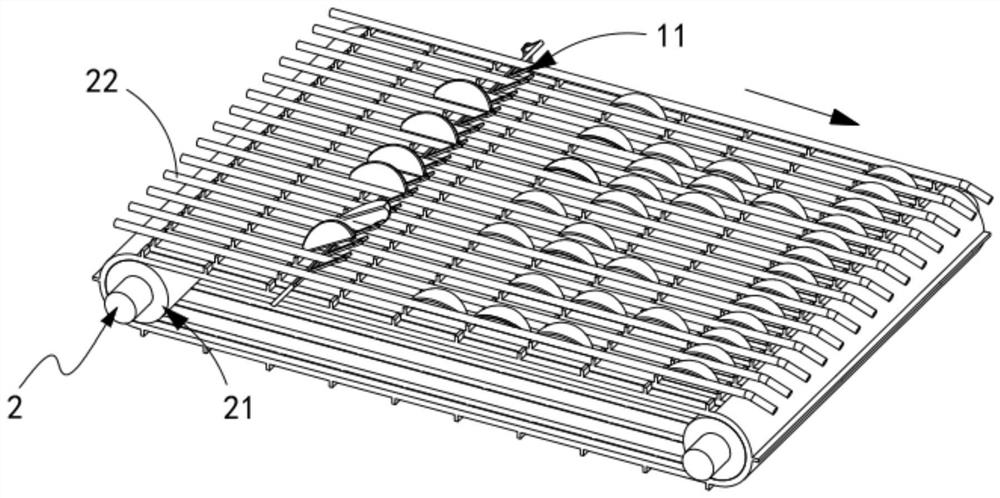

[0042] Such as figure 1 , figure 2 Shown, a kind of slicer for garlic food processing, comprises garlic clove feeder 1, feeding conveying device 2, slicing device 3, discharging conveying device 4 and driving mechanism 5, and described garlic clove feeder 1 is arranged on the described The head end of the feeding conveying device 2, the discharging conveying device 4 is arranged laterally at the tail end of the feeding conveying device 2, and the slicing device 3 is located above the discharging conveying device 4;

[0043] An adjusting assembly 11 is arranged below the garlic clove feeder 1, and the adjusting assembly 11 is located on the feeding conveying device 2;

[0044] The driving mechanism 5 drives the adjustment assembly 11 and the slicing device 3 to move up and down in the vertical direction;

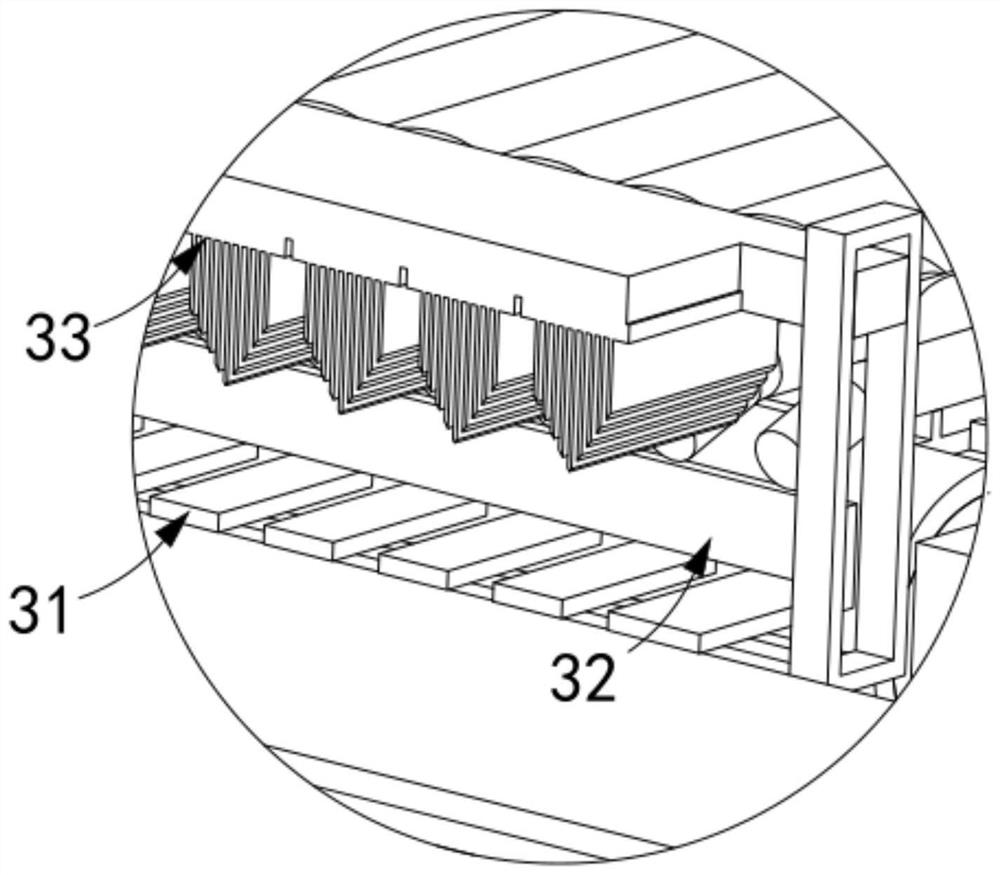

[0045] The slicing device 3 includes a support assembly 31 , a horizontal pushing assembly 32 slidably disposed on the support assembly 31 , and a cutting assembly 33 loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com