A jig for foaming refrigerator boxes

A technology for cabinets and refrigerators, which is applied in the field of foaming fixtures for refrigerator cabinets. It can solve the problems of reducing the force of the ball screw, the influence of wiring layout and space utilization, and slow lifting speed, so as to ensure the lifting speed and stability. High degree, high transmission accuracy and stability, and the effect of improving the loading space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

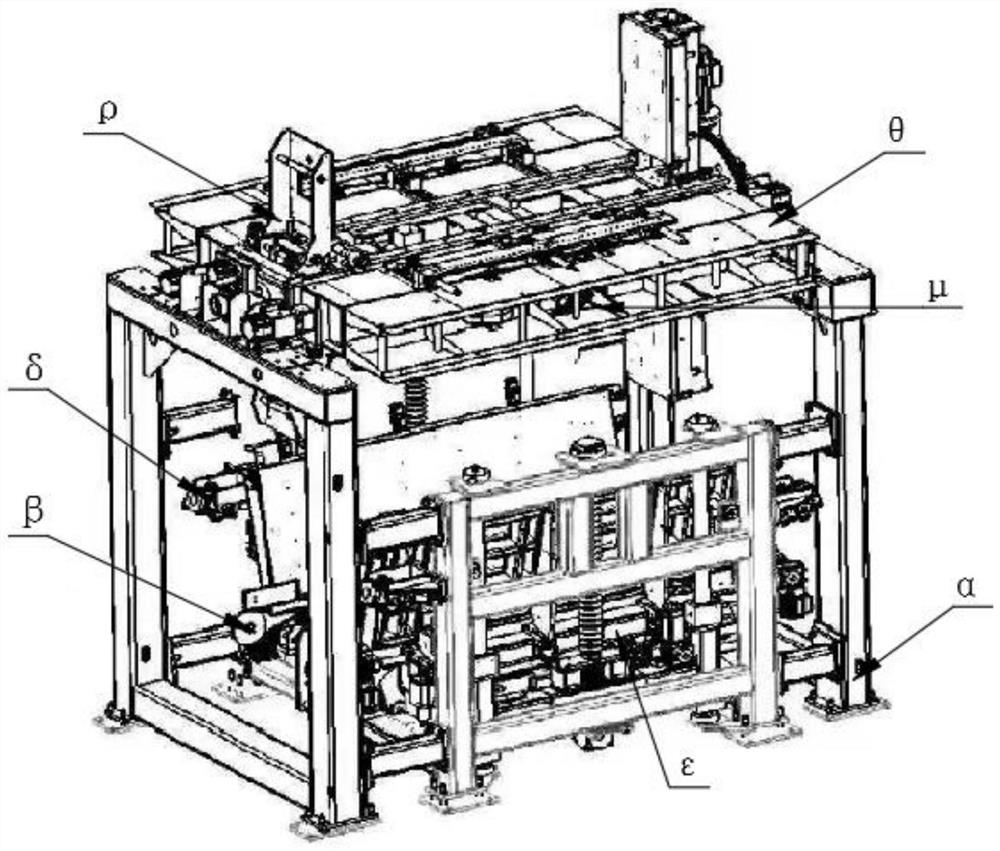

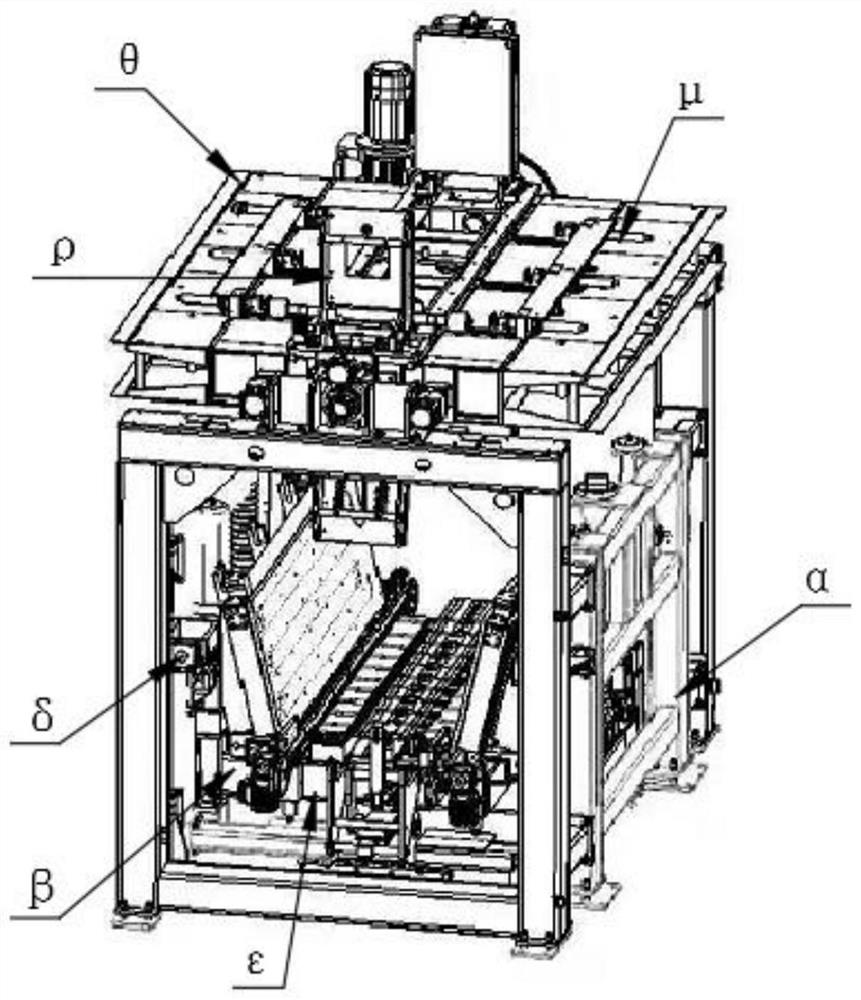

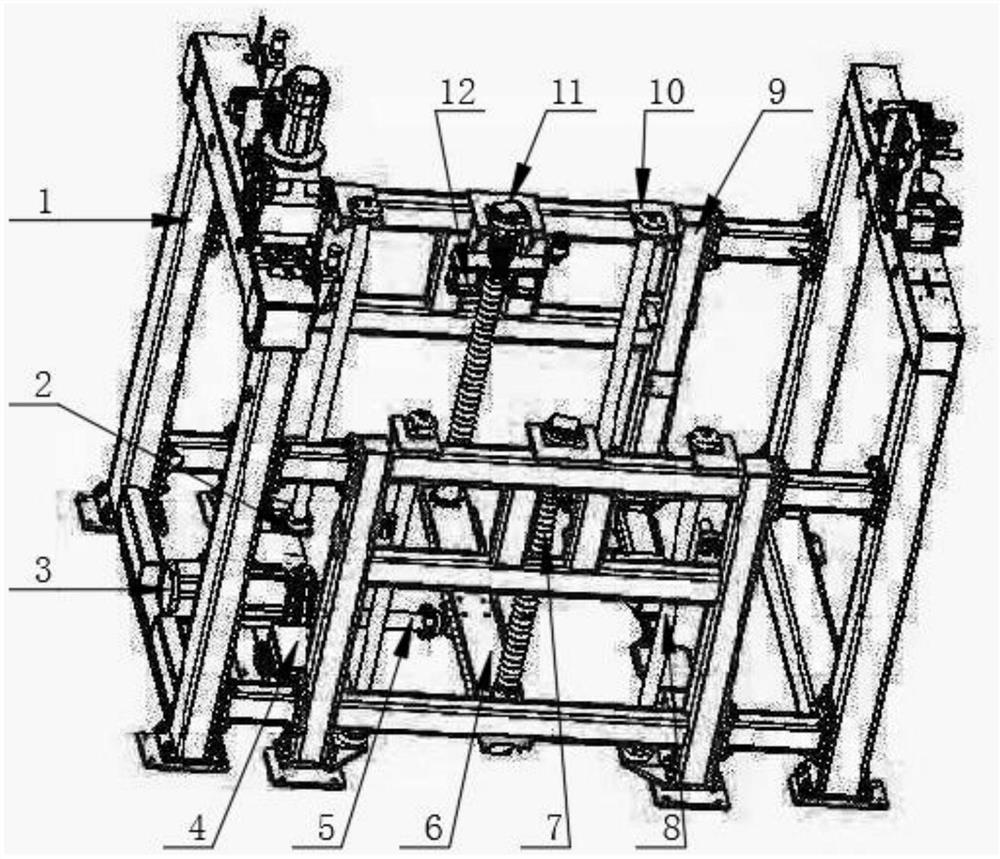

[0062] Such as Figure 1-17 As shown in Fig. 1, a fixture used for foaming refrigerator boxes, including lifting transmission mechanism α, belt conveying mechanism β, supporting pipe mechanism ε, locking mechanism δ, flip positioning mechanism θ, transmission limit mechanism μ and front baffle The limit mechanism ρ, the inside of the lifting transmission mechanism α is provided with a belt conveying mechanism β, the top of the belt conveying mechanism β is provided with a supporting pipe mechanism ε, and both sides of the lifting transmission mechanism α are correspondingly equipped with a locking mechanism δ, and the lifting transmission mechanism The center of the top of α is provided with an overturning positioning mechanism θ, and both sides of the overturning positioning mechanism θ are correspondingly provided with a transmission limiting mechanism μ, and the top and bottom of the overturning positioning mechanism θ are respectively provided with a front baffle limiting m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com