Thermomechanical treatment method of eutectic high-entropy alloys

A technology of thermo-mechanical treatment and high-entropy alloy, which is applied in the field of materials to achieve the effects of improving mechanical properties, improving strength and plasticity, and promoting the formation of precipitates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

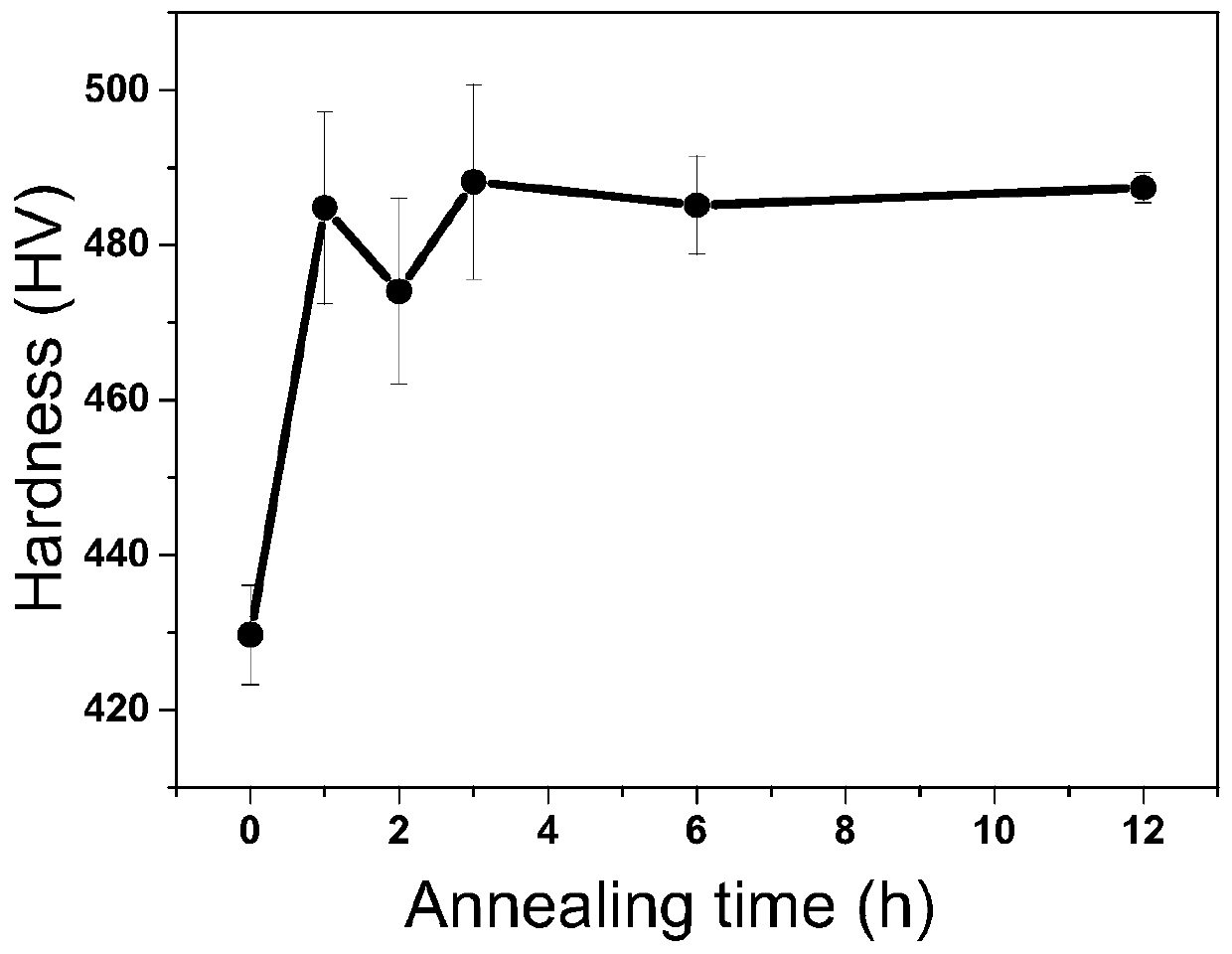

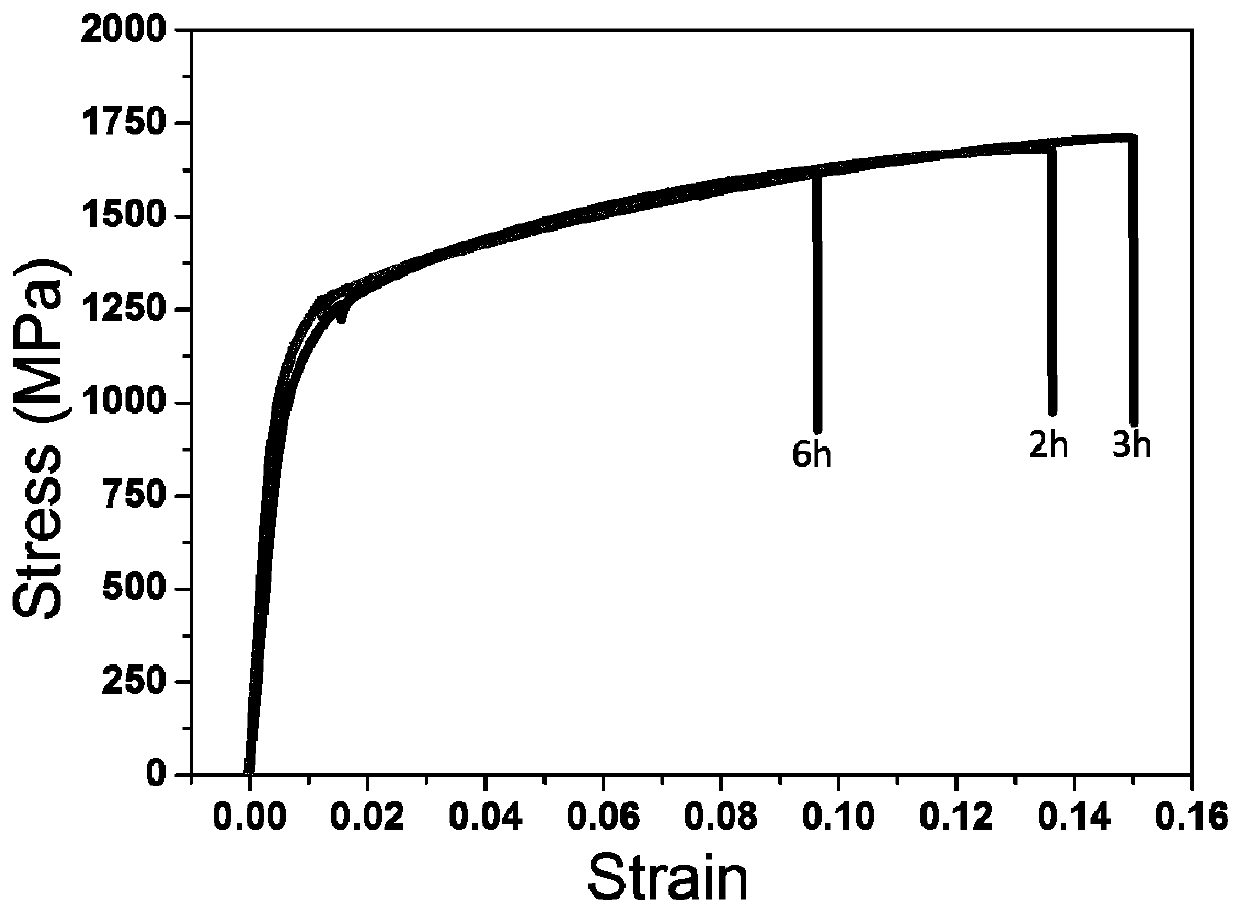

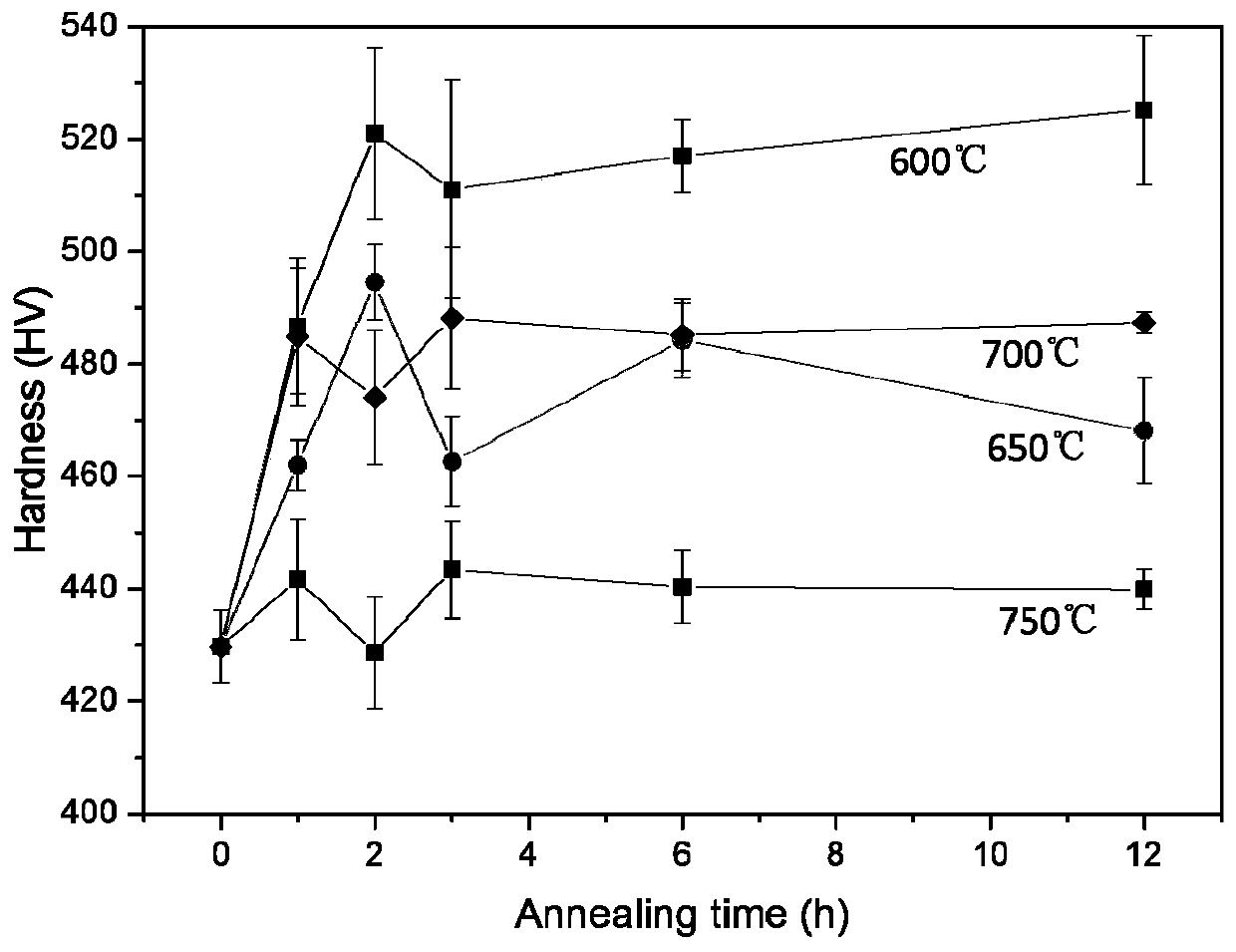

Embodiment 1

[0035] Ni 30 co 30 Fe 10 Cr 10 al 18 W 2 A thermomechanical treatment method for eutectic high-entropy alloys, comprising the following steps:

[0036] S1, Ni 30 co 30 Fe 10 Cr 10 al 18 W 2 Preparation of Eutectic High Entropy Alloys

[0037] Alloy ingredients: Use the mechanical grinding method to remove the oxide skin on the surface of the elements of Ni, Co, Fe, Cr, Al, W, then place them in different containers and add alcohol solution, ultrasonic cleaning, take out and dry the alcohol to obtain ultrasonic treatment After the six kinds of raw materials, the six kinds of metal raw materials are pretreated according to Ni 30 co 30 Fe 10 Cr 10 al 18 W 2 Mole percentage weighing of eutectic high-entropy alloy;

[0038] Master alloy smelting: put Ni, Co, Fe, Cr, W raw materials into the crucible of vacuum induction melting furnace, put the preheated steel ingot mold into the furnace, hang Al above the crucible through Ni wire; vacuumize with mechanical pump A...

Embodiment 2

[0047] The method is the same as in Example 1, except that the aging treatment time in S3 is 1 h.

Embodiment 3

[0049] The method is the same as in Example 1, except that the aging treatment time in S3 is 2 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com