Heat treatment method that can effectively reduce the anisotropy of laser additive manufacturing titanium alloy

A heat treatment method and laser additive technology, which is applied in the direction of additive manufacturing, additive processing, and energy efficiency improvement, can solve problems such as poor plasticity, easy-induced cracks, and prominent anisotropy of formed parts, and achieve the effect of eliminating internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

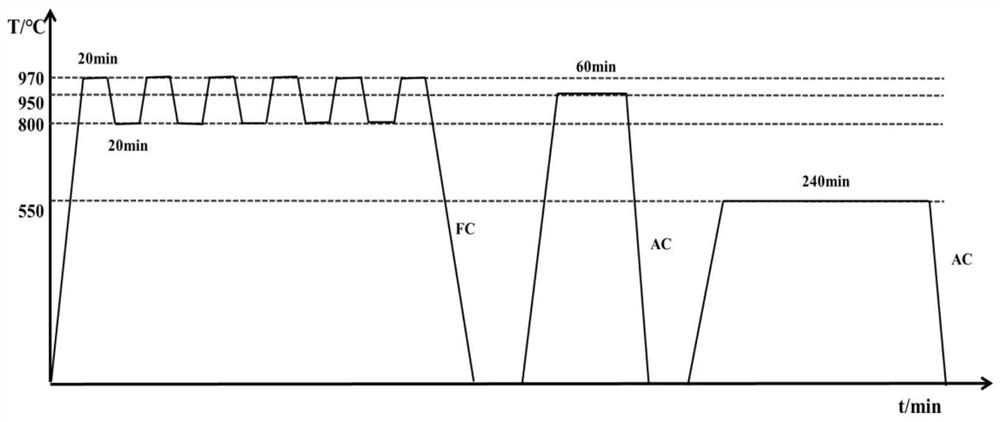

[0023] The invention provides a heat treatment method capable of effectively reducing the anisotropy of titanium alloy manufactured by laser additive manufacturing, which specifically includes the following steps:

[0024] Step 1. Put the titanium alloy sample manufactured by laser additive manufacturing into a vacuum tube furnace, start vacuuming until the vacuum pressure is -0.1MPa, stop vacuuming, feed argon gas to balance the pressure, and repeat the vacuuming for 5 times. Introduce argon protection. Turn on the tube furnace switch to start heating up, the heating rate is controlled at 12°C / min, the temperature is raised to 970°C and kept for 20 minutes, and then cooled with the furnace, the cooling rate is 9°C / min, and the temperature is cooled to 800°C and kept for 20 minutes;

[0025] Step 2, continue to heat up, the heating rate is contro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com