A speed shifting method of a wrap-around common rail in-line gearbox

A gearbox and wrap-around technology, applied to components with teeth, transmission parts, belts/chains/gears, etc., can solve the problems of shortened gear life, energy loss, complex structure, etc., to save resources and facilitate operation , The effect of high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0046] In conjunction with the accompanying drawings of the present invention, specific embodiments are as follows:

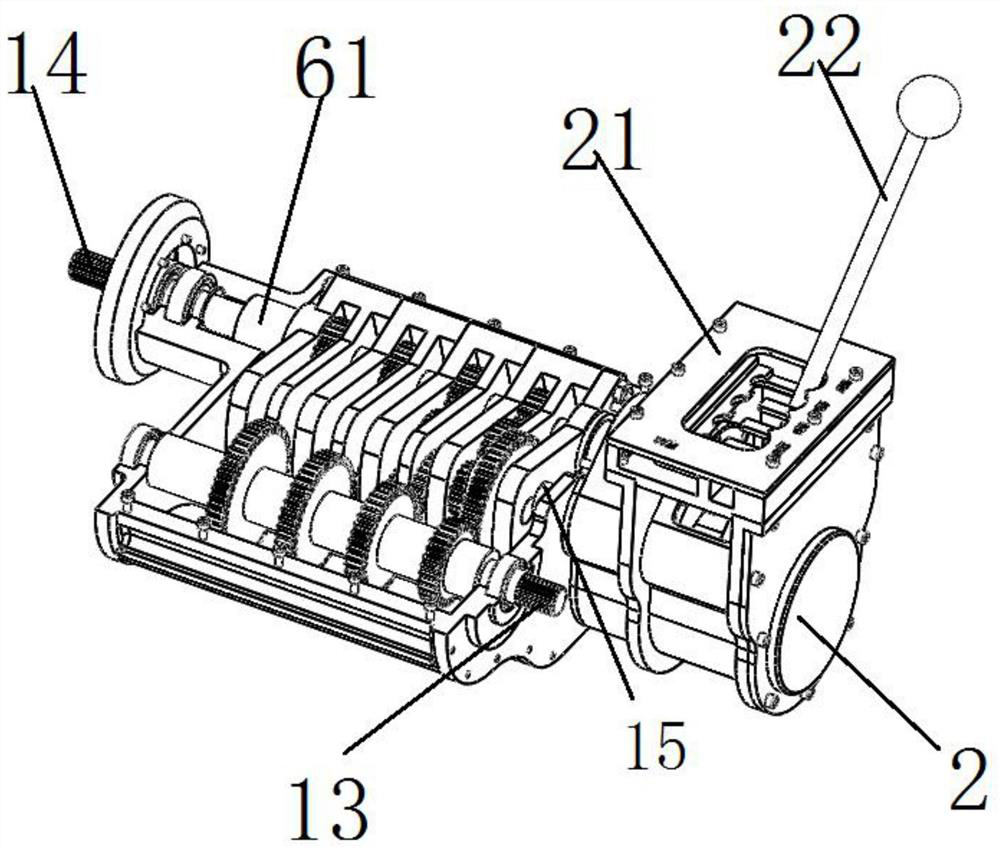

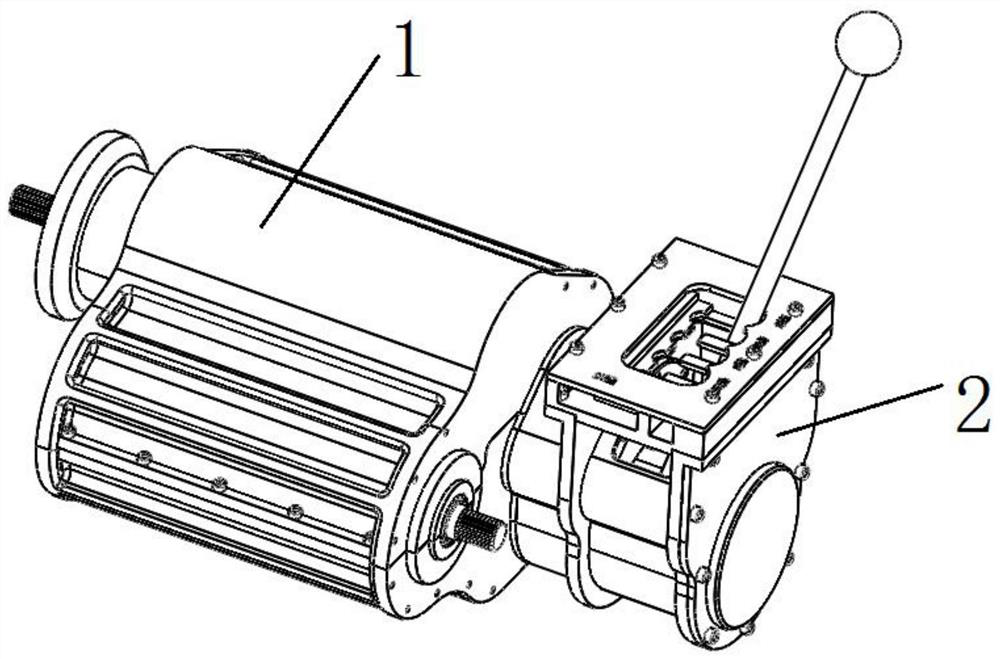

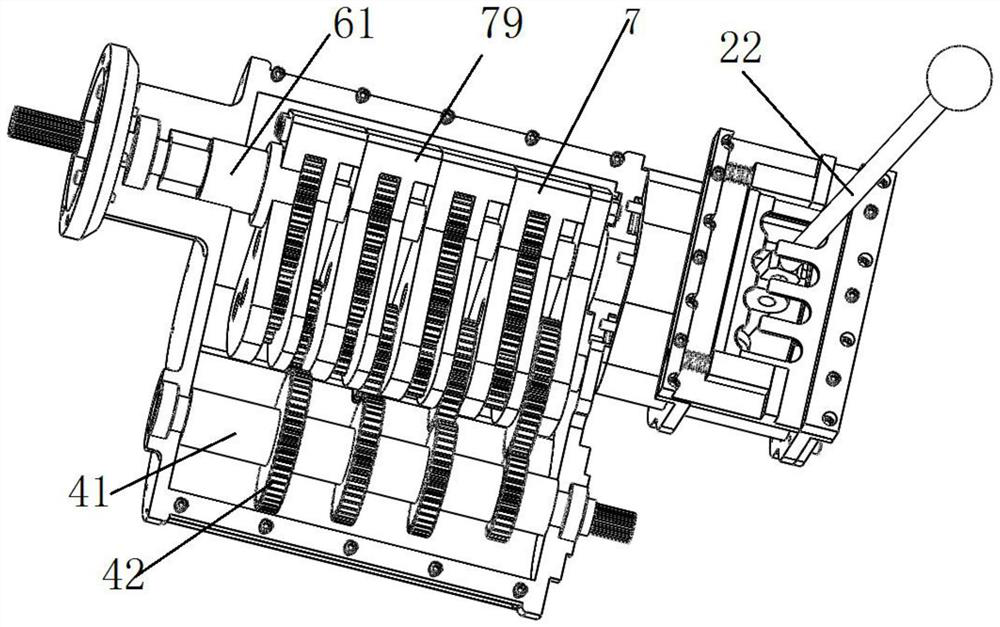

[0047] A wrap-around common rail in-line gearbox, including:

[0048] Gearbox housing 1, the inner two sides of the gearbox housing 1 are respectively movably erected with a main shaft 11 and a countershaft 12 parallel to each other, the output end of the main shaft 11 is connected with a power output shaft 13, and the countershaft 12 The input end of the transmission case 1 is connected with a power input shaft 14, and the inner side of the side panel adjacent to the shift adjustment box 2 of the gearbox housing 1 is provided with a horizontal guide post 15;

[0049] The shift adjustment box 2, the shift adjustment box 2 is located on one side of the gearbox housing 1, the top of the shift adjustment box 2 is provided with a gear card 21, and the shift adjustment box 2 is connected with a wear The shift handle 22 of the shift card 21, the bottom of the shift ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com