Shot hole periphery loose ballast clearing device for detonation

A technology for cleaning devices and ballast, applied in blasting and other directions, can solve problems such as low work efficiency, affecting blasting accuracy, troublesome operation, etc., and achieve high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

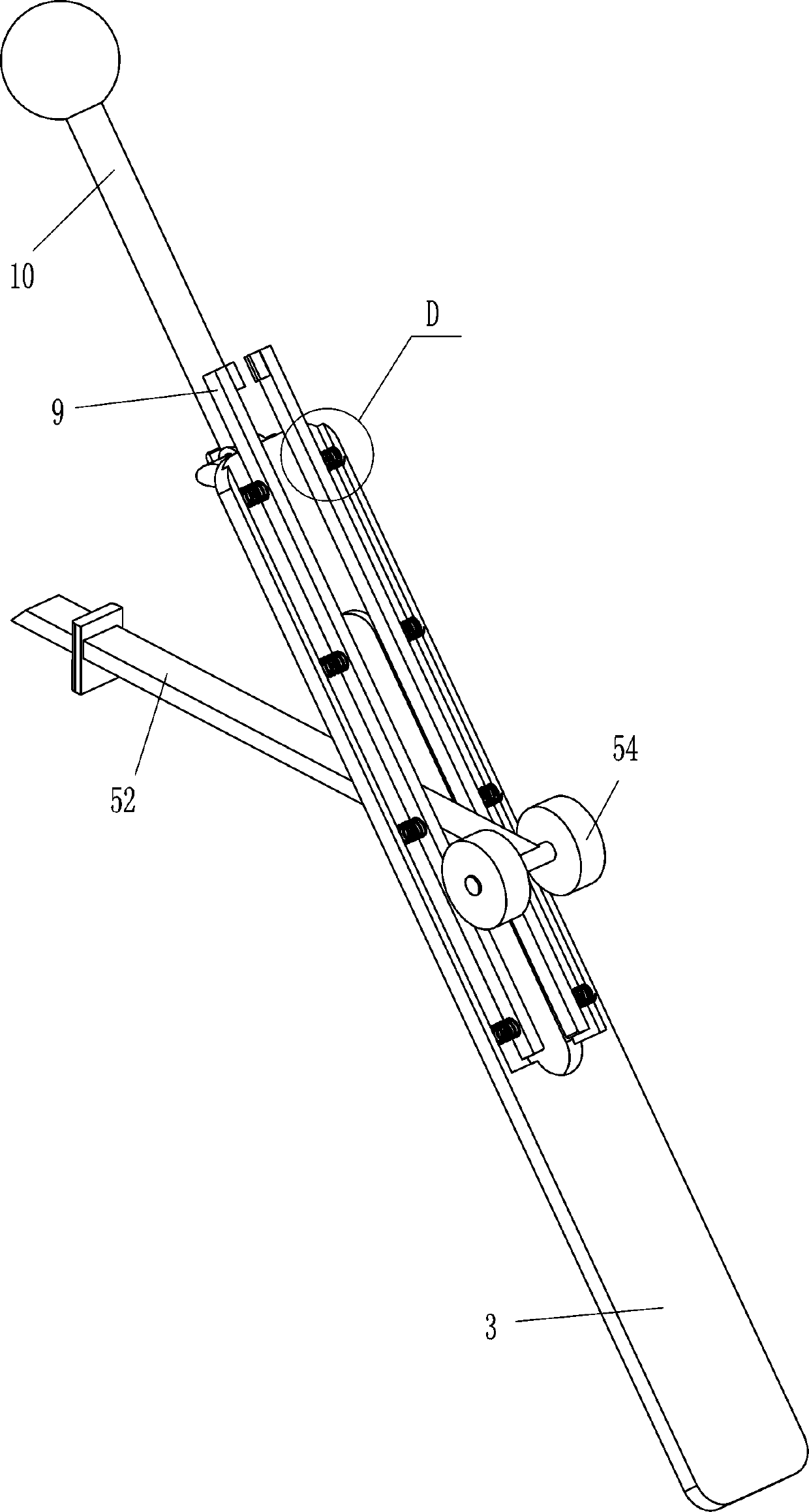

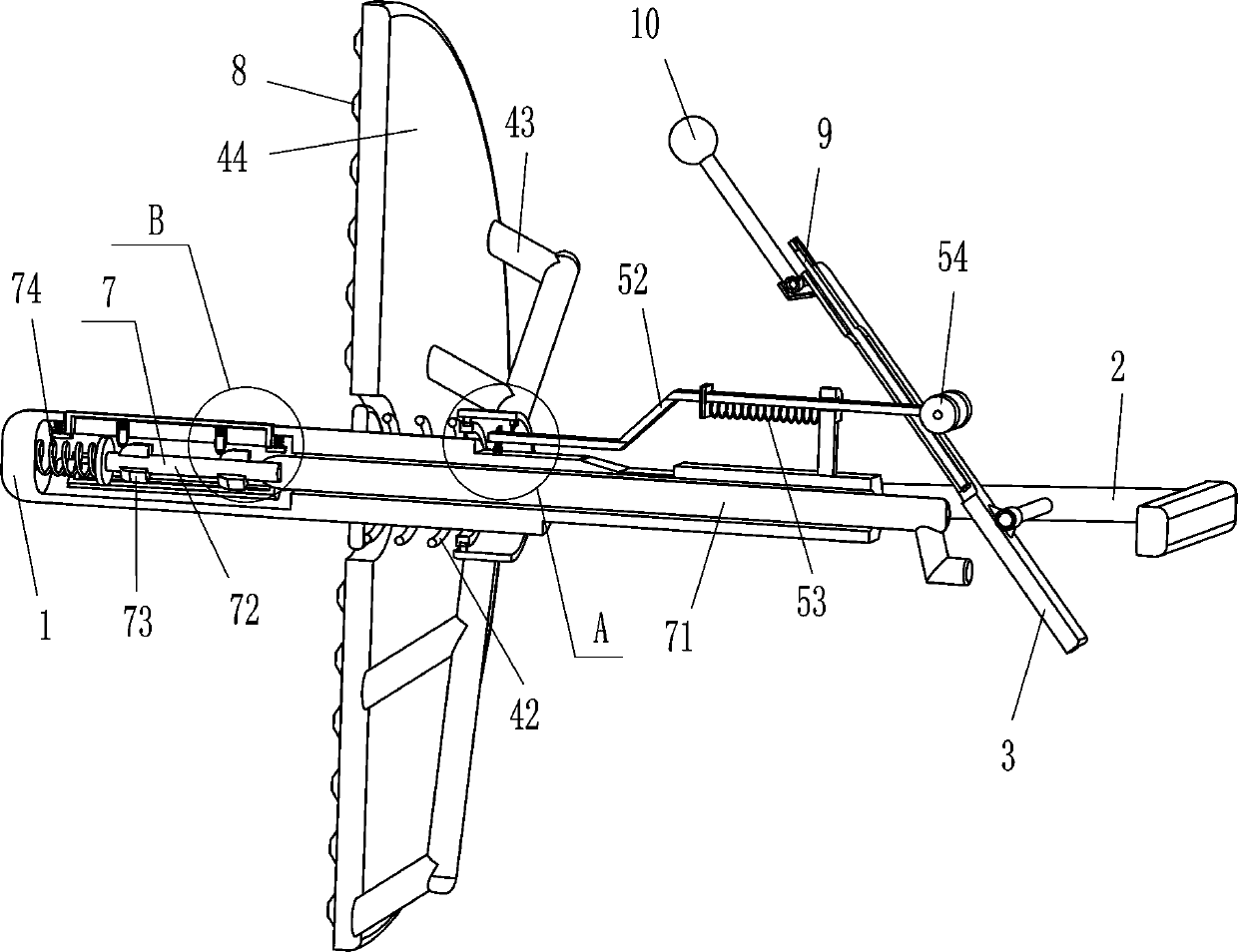

[0024] refer to Figure 1-Figure 5 , a device for cleaning loose ballast around blastholes for blasting, comprising a hollow chute rod 1, a handle 2, a hollow in-line orifice plate 3, a compacting mechanism 4 and a driving mechanism 5, and the right side of the outer side of the hollow chute rod 1 is fixed. A handle 2 is connected, and a hollow in-line orifice plate 3 is hinged between the middle parts of the front and rear sides of the handle 2, and a drive mechanism 5 is provided between the hollow in-line orifice plate 3 and the outer top right side of the hollow chute rod 1, and the hollow chute A compacting mechanism 4 is provided in the middle of the rod 1, and the compacting mechanism 4 is connected with a driving mechanism 5.

[0025] The compacting mechanism 4 includes an annulus 41, the first spring 42, a connecting rod 43 and a beating plate 44. The hollow chute bar 1 middle part slide type is provided with an annulus 41, and the left side of the annulus 41 is conne...

Embodiment 2

[0031] refer to figure 1 , figure 2 and Figure 6 Compared with Embodiment 1, the main difference of this embodiment is that in this embodiment, a fixing mechanism 7 is also included, and the fixing mechanism 7 includes a movable rod 71, a sliding rod 72, an arc block 73, a third spring 74, an arc Plate 75, the 4th spring 76, sleeve 77, circular bar 78 and the 5th spring 79, hollow chute bar 1 sliding type is provided with movable rod 71, movable rod 71 cooperates with hollow word orifice plate 3, movable rod The left end of 71 is fixedly connected with a slide bar 72, the third spring 74 is connected between the left end of the slide bar 72 and the inner left side of the hollow chute bar 1, and the left and right sides of the outside of the slide bar 72 are evenly spaced with arc-shaped blocks 73 , the left part of the hollow chute bar 1 is evenly spaced circumferentially and embedded with arc-shaped plates 75, and a fourth spring 76 is connected between the left and right...

Embodiment 3

[0034] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 7 and Figure 8 Compared with Embodiment 1 and Embodiment 2, the main difference of this embodiment is that this embodiment also includes bumps 8, and the left side of the beating plate 44 is fixedly connected with bumps 8 at even intervals.

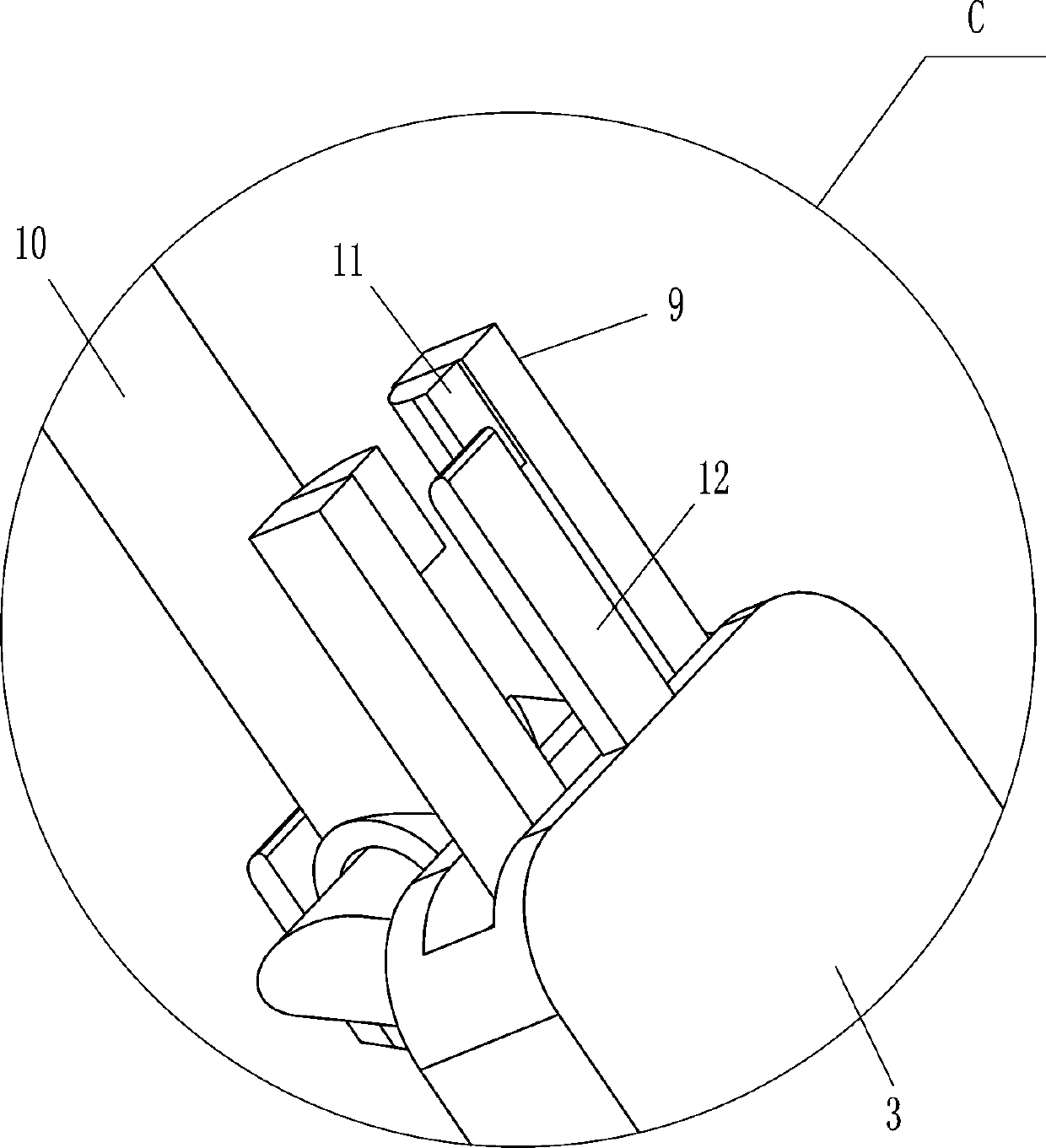

[0035] It also includes a friction clamping plate 9, a swing lever 10, an arc contact block 11, a limit plate 12 and a sixth spring 13, and the friction clamping plate 9 is slidingly provided on the front and rear sides of the hollow in-line hole plate 3. , the inner surface of the friction clamping plate 9 is in contact with the side surface of the special-shaped plate 52, and the sixth spring 13 is evenly spaced between the outer surface of the friction clamping plate 9 and the inner surface of the hollow orifice plate 3, and the friction clamping plates on the front and rear sides The upper part of the inner surface of 9 is fixedly connected with an arc-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com