Bearing residual life prediction method based on binary hybrid random process

A stochastic process, life prediction technology, applied in CAD numerical modeling, design optimization/simulation, etc., to achieve the effect of improving prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be further described below in conjunction with the accompanying drawings.

[0068] refer to Figure 1 to Figure 5 , a method for predicting the remaining life of a bearing based on a binary mixed stochastic process, the method comprising the following steps:

[0069] S1. Collect the vibration signal and temperature signal of the bearing degradation stage;

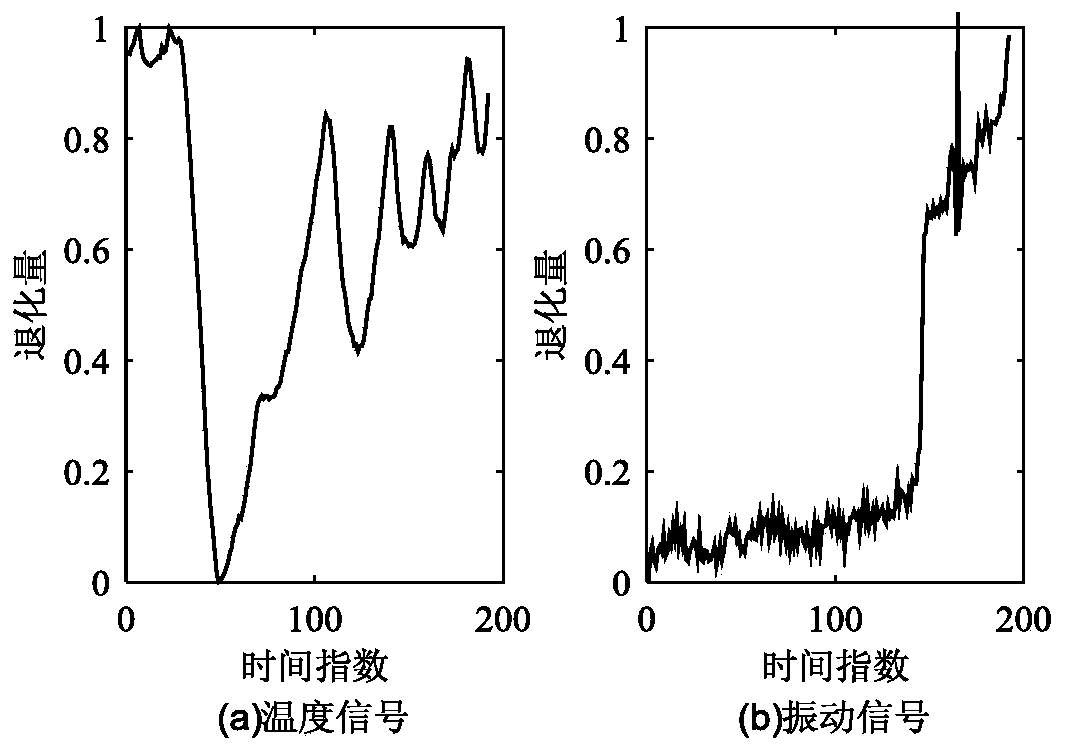

[0070] S2. Calculate the effective value of the vibration signal and the average value of the temperature signal respectively, and construct two performance indexes representing the healthy state of the bearing (as attached figure 1 shown), proceed to subsequent steps based on these two performance indicators;

[0071]

[0072]

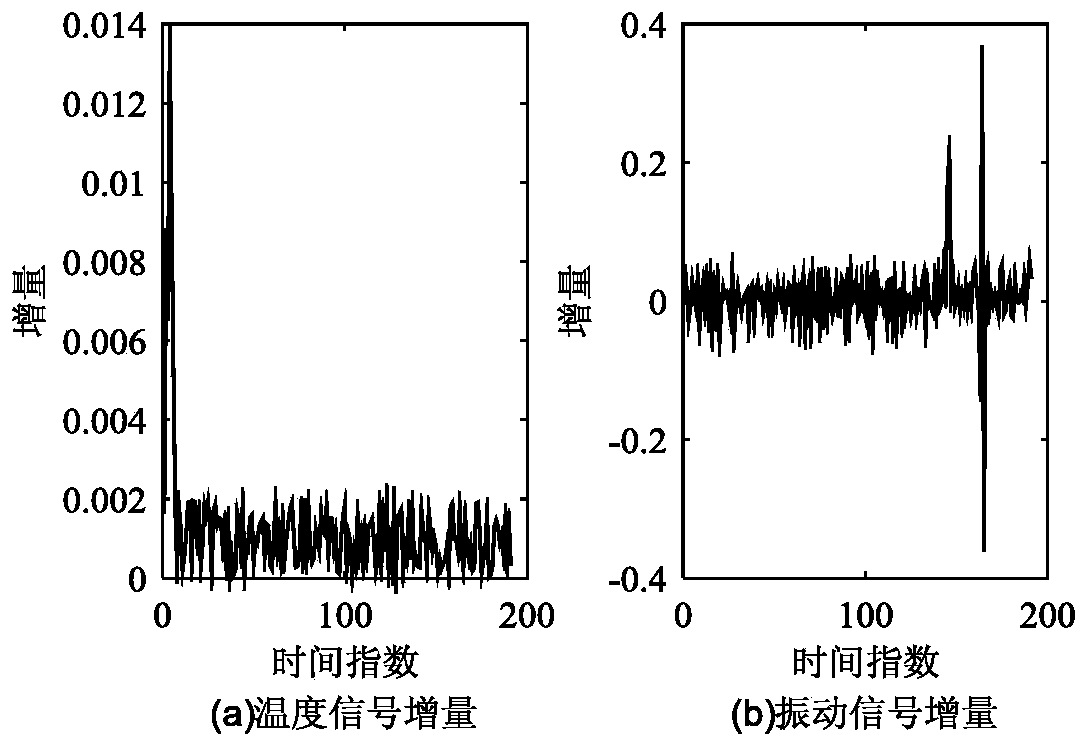

[0073] Among them, the change range of the average value of the temperature signal is not a non-decreasing process, which does not conform to the monotonically increasing nature of the gamma process, so the temperature signal needs to be preprocessed. Accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com