Wet type ultrasonic refining equipment for solid waste, comprehensive treatment system and method

A solid waste and ultrasonic technology, which is applied in the field of comprehensive treatment systems and wet ultrasonic refinement equipment, can solve the problems of reducing the comprehensive treatment efficiency of solid waste, insufficient solid waste crushing, and difficult removal of pollutants, etc., and is suitable for large-scale The effects of promotion, good learning and reference, and thorough fragmentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings.

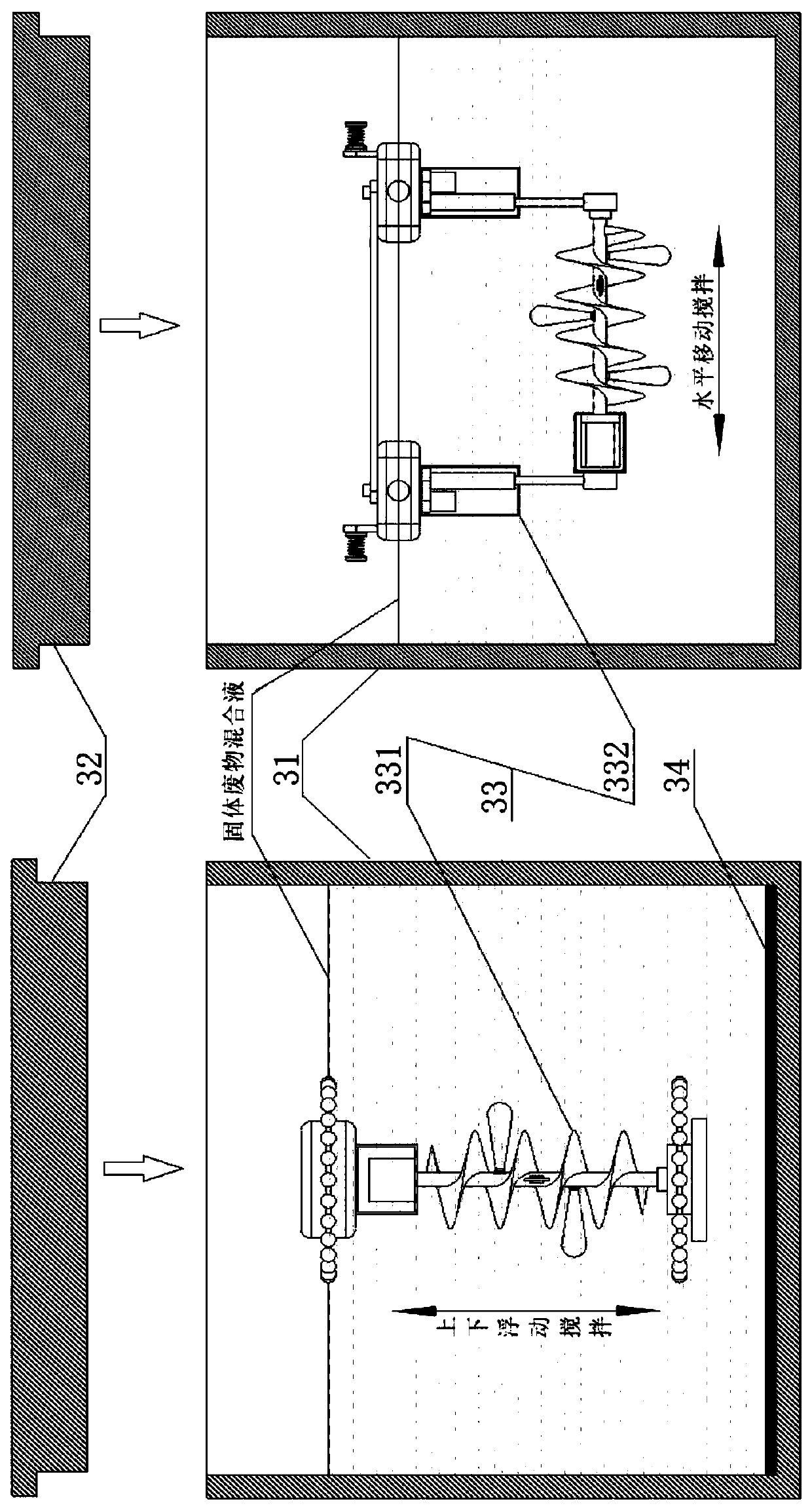

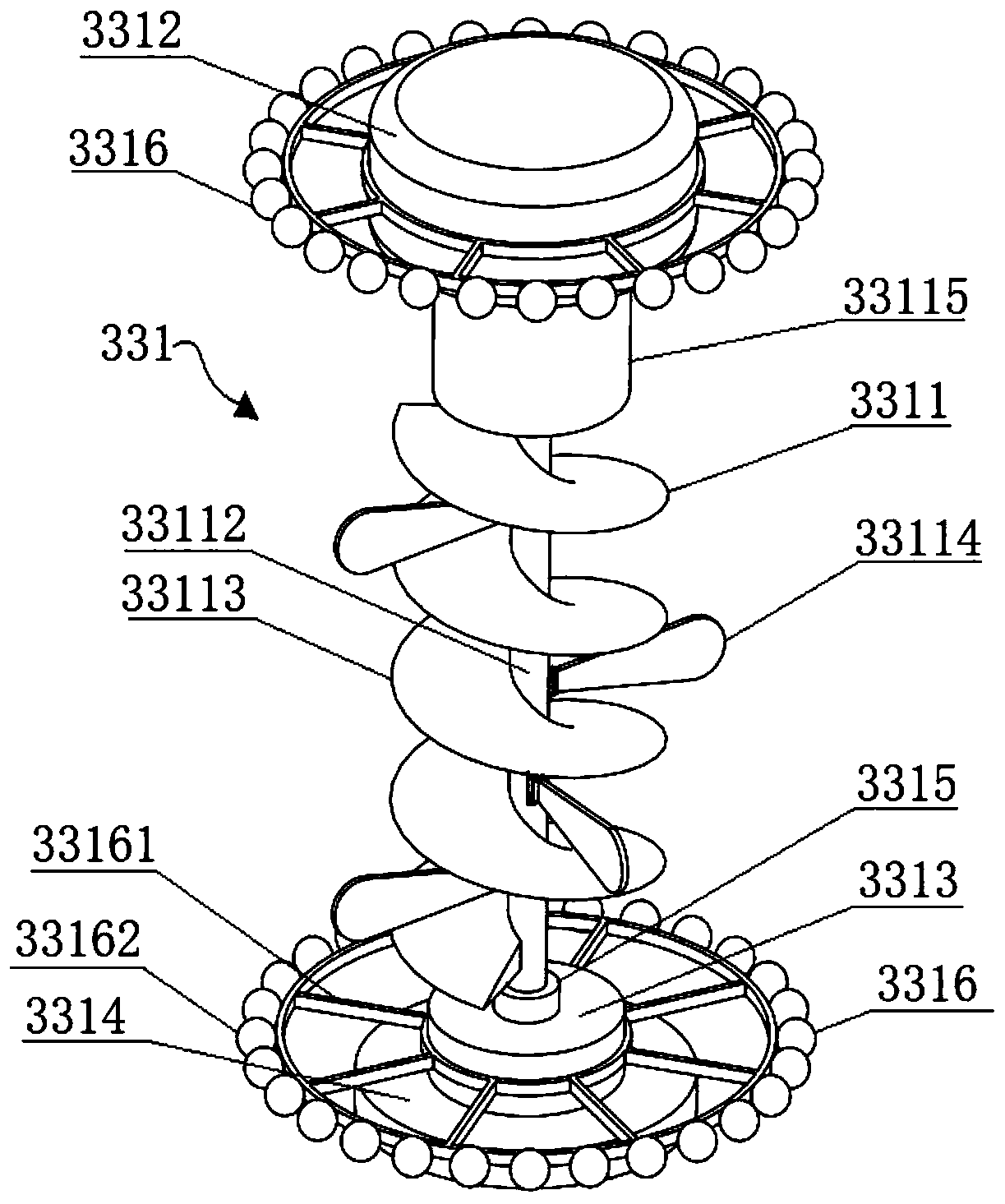

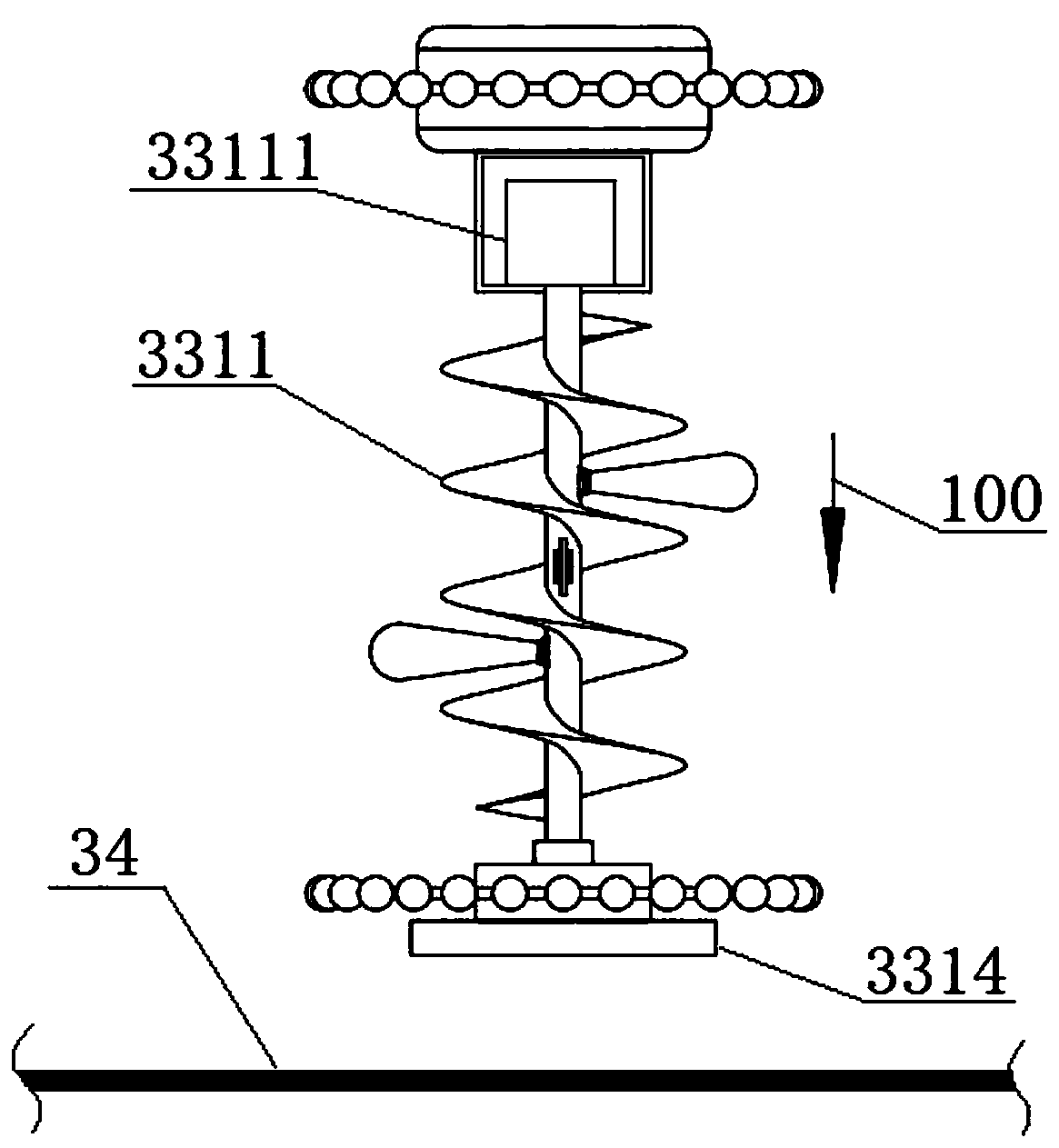

[0046] as attached figure 1 As shown, the wet ultrasonic refinement equipment for solid waste includes a wet ultrasonic refinement equipment 3, the wet ultrasonic refinement equipment 3 includes an ultrasonic breaker container 31 and a detachable cover 32, and the ultrasonic breaker container 31 has a top The device mouth, the detachable cover 32 is sealed on the top device port to seal the ultrasonic crushing container 31; the wet ultrasonic refining equipment 3 also includes a floating stirring unit 33, which floats on the ultrasonic Break the liquid level of the solid waste mixed liquid in the container 33, and the stirring part of the floating stirring unit 33 is immersed in the solid waste mixed liquid; the reverse thrust of the floating stirring unit 33 stirring the solid waste mixed liquid by its stirring part The waste mixture is in an active stirring state. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com