Rotating block type derailer device

A derailer and rotating block technology, which is used in transportation and packaging, equipment fixed to the track, railway car body parts, etc., can solve the problem that the height of the stop block cannot be too high, the train cannot be safely derailed, and the derailment head is easy to retreat, etc. problems, to achieve the effect of flexible adjustment in place, ingenious design ideas, and high safety and reliability coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

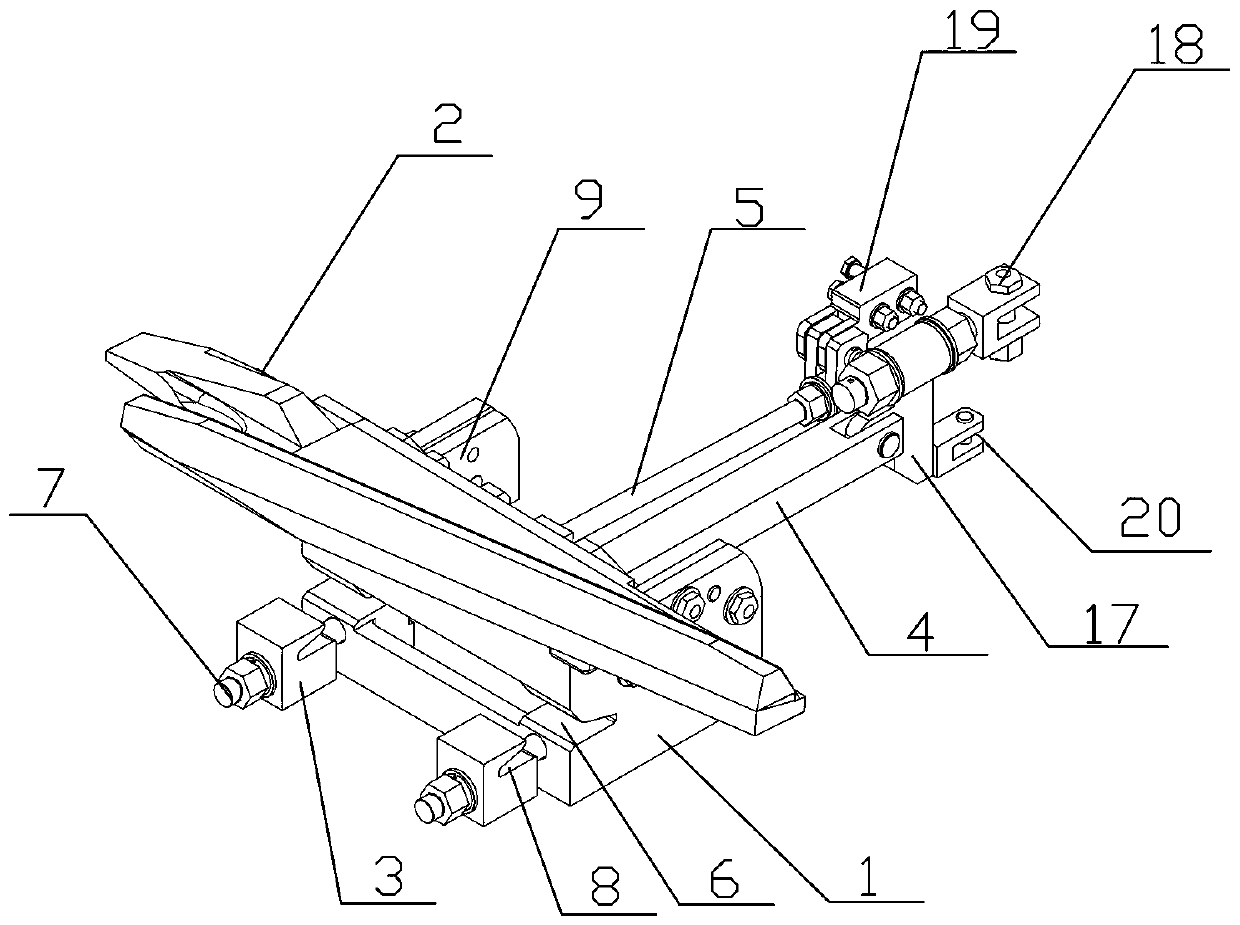

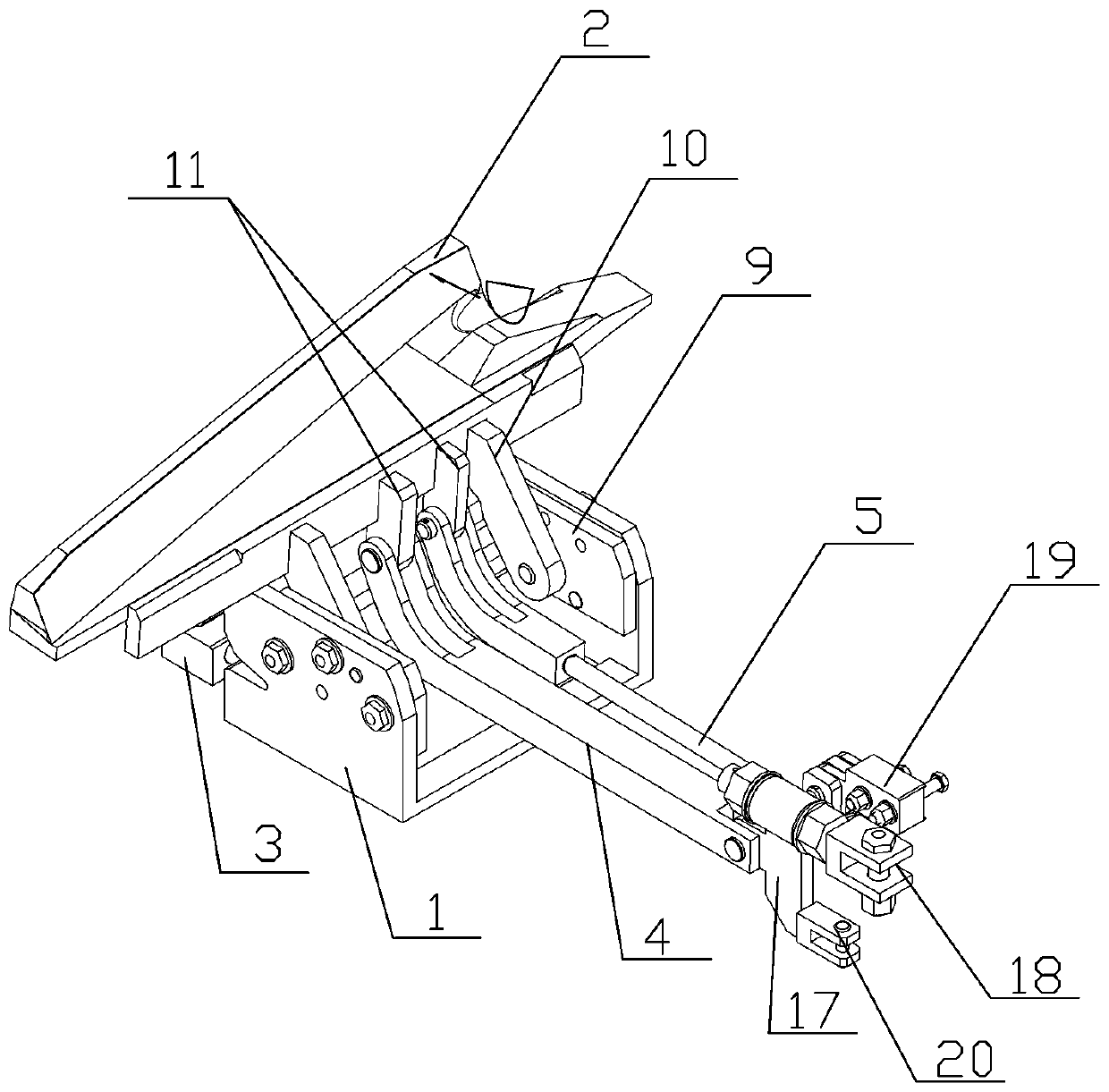

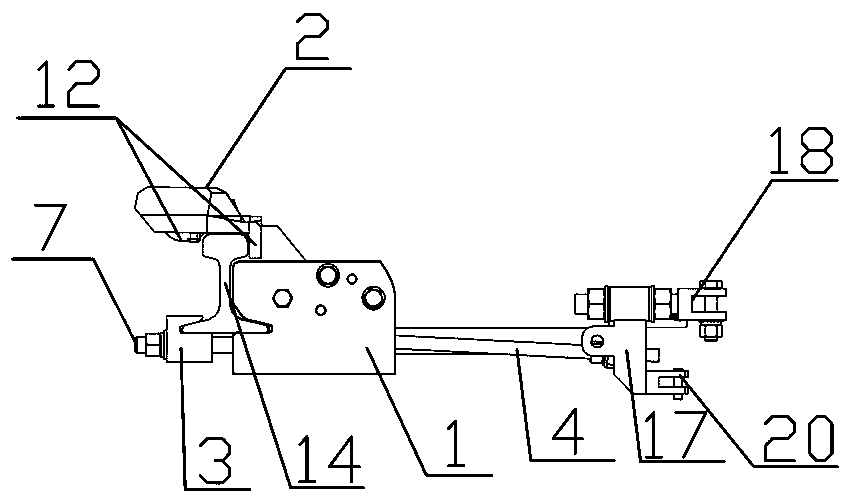

[0015] see Figure 1-5 , the present embodiment of the present invention rotating block type derailer device, including a base 1, a derailment head 2, a rail block 3, a main push-pull rod 4, a driven rod 5, a main push-pull rod adapter 17, a driven rod adapter 19 and adjustment Rod 18, the front end of the base is provided with a rail slot A6, at least one bolt rod 7 is provided on the base below the rail slot A, the bolt rod is equipped with a rail block, and the rail block is provided with a rail Card slot B8, a transition support plate 9 is respectively provided on both sides of the base, and a first-level ear plate 10 is arranged on each transition support plate, one end of the first-level ear plate is hinged with the transition support plate, and the other end of the first-level ear plate is hinged. One end is fixedly connected to the derailment head, and two secondary ear plates 11 are arranged side by side between the two primary ear plates. One end of the two secondary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com