Fuel cell membrane electrode performance test method

A technology of fuel cell membrane and testing method, which is applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., and can solve the problems of inability to evaluate performance, performance attenuation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

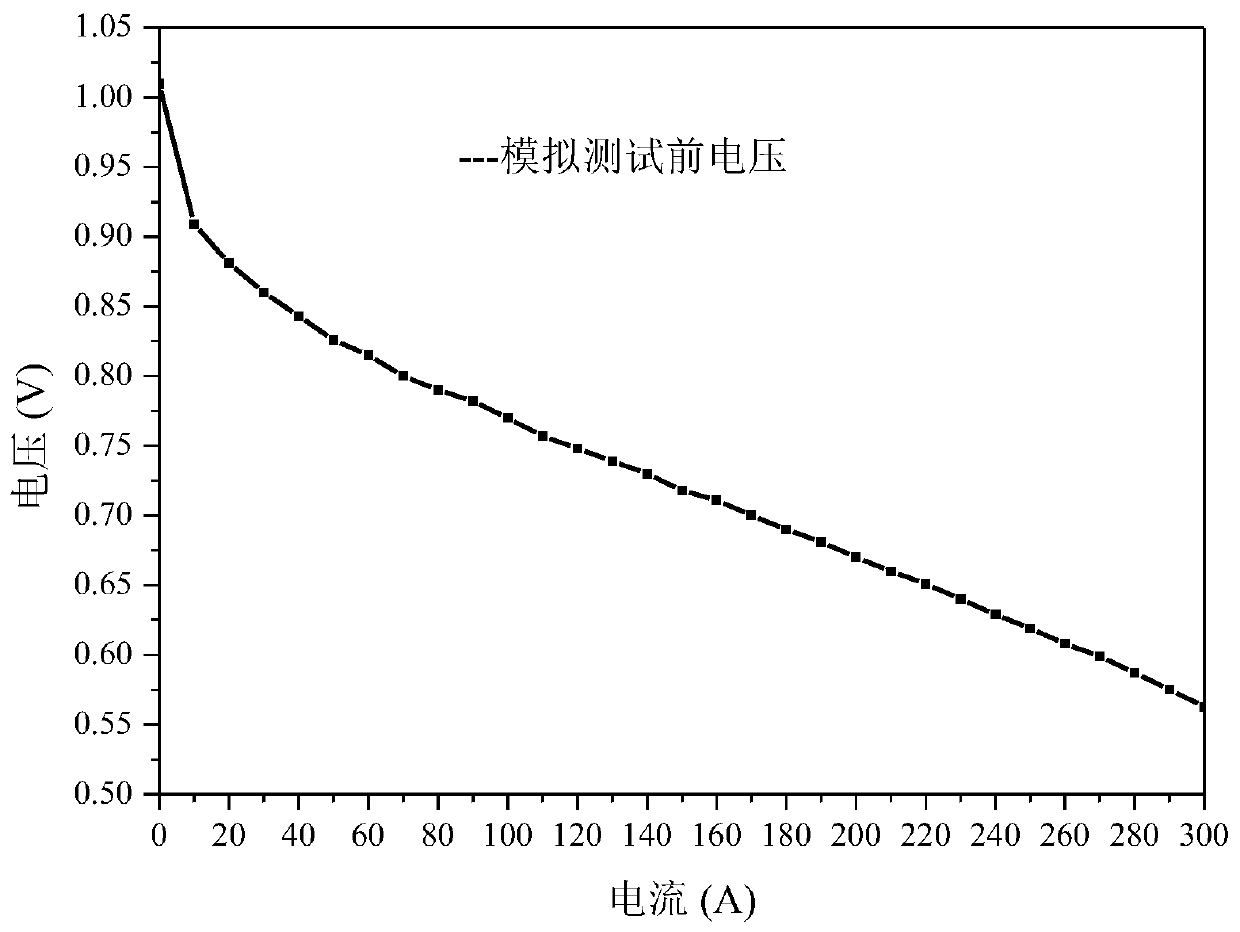

[0090] Example 1 Membrane electrode polarization curve test before simulating vehicle working conditions

[0091] Step 1: Assemble the fuel cell stack with the membrane electrode, bipolar plate and other accessories, install it on the test platform, connect the gas and cooling water pipes, and check the air tightness.

[0092] Step 2: Pass N2 through the cathode and anode of the battery stack to purge the battery stack.

[0093] Step 3: Set test conditions including temperature, humidity, flow, pressure test

[0094] Step 4: Activate the stack according to the selected test conditions.

[0095] Step 5: After the activation is completed, select the constant current mode for the test, the test current range is 0-300A, the test current point interval is 10A, and each load lasts for 1min. After the performance is stable, record the voltage value and power value, and test the stack membrane electrode Polarization curve performance.

Embodiment 2

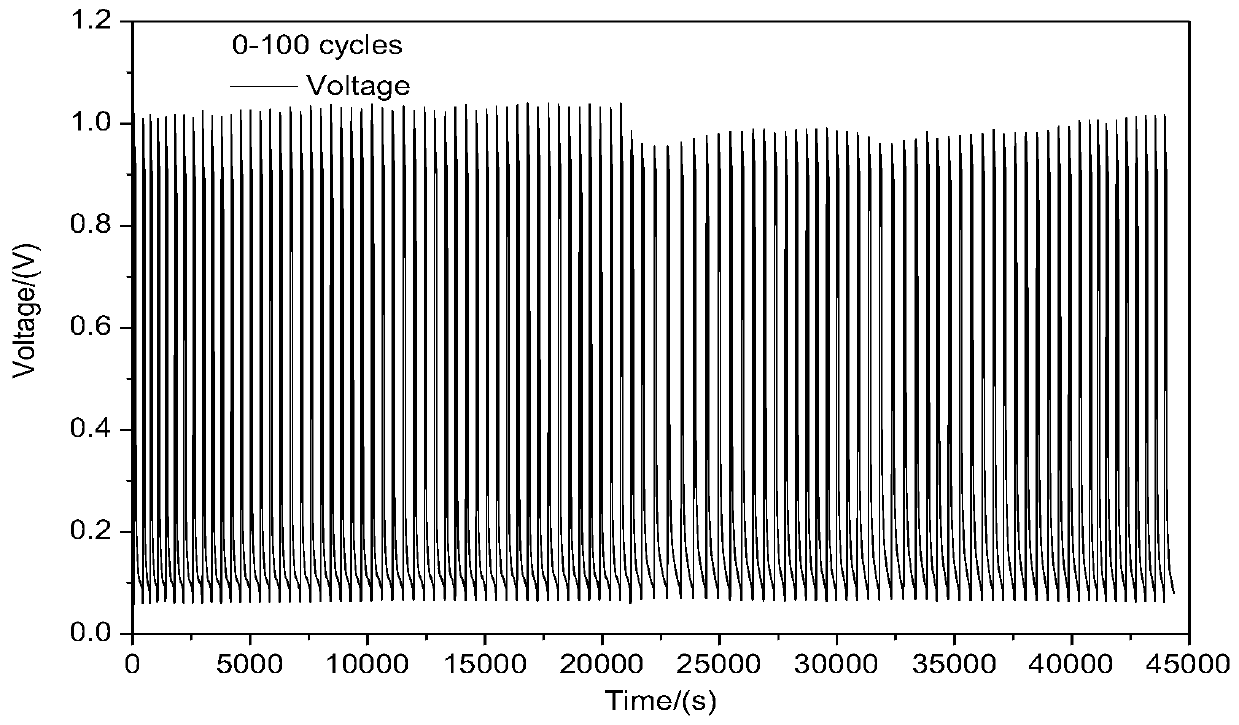

[0096] Embodiment 2 simulates the start-stop experimental test of vehicle operating conditions

[0097]Step 6: Carry out a simulated on-board working condition test. Test method: The air on the cathode side is normally open, the anode is first fed with H2 to raise the voltage of the single cell to OCV (open circuit voltage) and maintained for 1min, then the anode inlet H2 is closed, and the air is fed from the anode outlet to the cell. The hydrogen is purged, and the battery voltage drops to the lowest stable voltage for 1 minute, which is a complete start-stop cycle. After a start-stop cycle, close the air at the anode outlet, open the H2 at the inlet, and start a new start-stop cycle. Set to repeat the above test procedure test 100 times to complete the simulated vehicle working condition test.

[0098] Step 6 may also preferably include the following steps (step 6.1: feed N2 to the cathode and anode of the battery stack, and purging the battery stack.

[0099] Step 6.2: ...

Embodiment 3

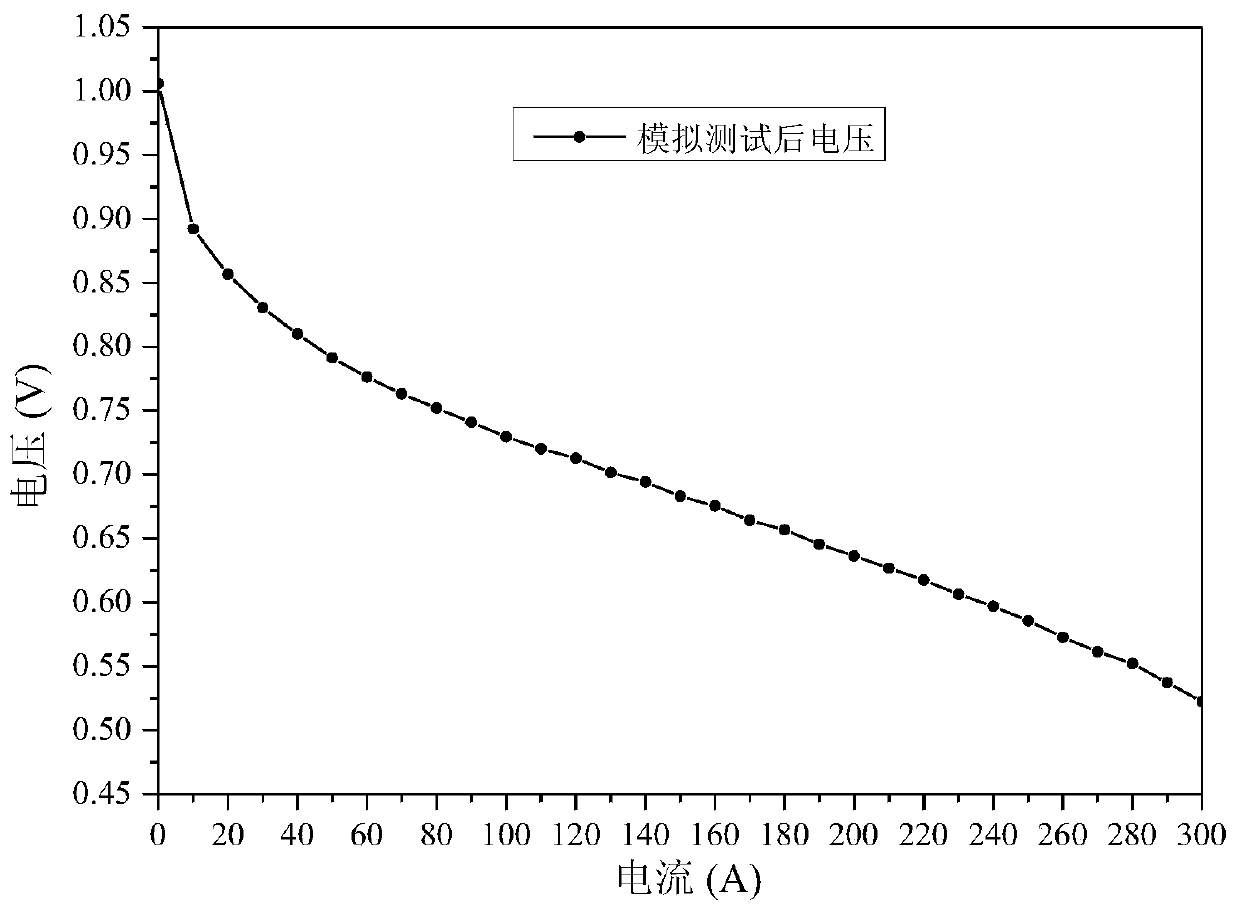

[0102] Example 3 After simulating the vehicle working conditions, the membrane electrode polarization curve test

[0103] Step 8: Start the test program, pass N2 to the cathode and anode of the battery stack, and purge the battery stack.

[0104] Step 9: Set test conditions including temperature, humidity, flow, pressure test

[0105] Step 10: Test the polarization curve of the membrane electrode after the simulated working condition. The test current range is 0-300A, the test current point interval is 10A, and each loading lasts for 1min. After the performance is stable, record the voltage value and power value, and test the stack Polarization curve performance of membrane electrodes.

[0106] Step 11: After simulating the vehicle working conditions, after the polarization curve test is completed, pass N2 to the cathode and anode of the battery stack to purge the battery stack.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com