Connector assembly and plug

A connector and cable connector technology, applied in the direction of connection, connecting device parts, two-part connecting device, etc., can solve the problems of easy tearing, time-consuming and labor-intensive protective cover, etc., to reduce assembly difficulty, avoid tearing, Guaranteed effect of protection reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

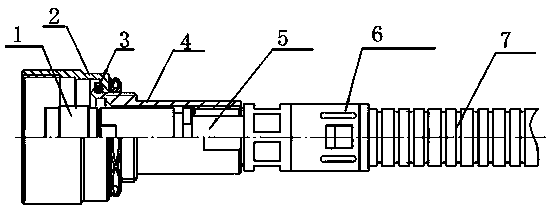

[0080] Specific embodiment 2 of the connector assembly of the present application: The difference between this embodiment and embodiment 1 is that the limit structure is different. Stop fit, outer side and varus edge stop fit. As another example, the circumferential blocking protrusion may be a single protrusion or a plurality of protrusions distributed at intervals along the circumferential direction.

specific Embodiment 3

[0081] Specific embodiment 3 of the connector assembly of the present application: The difference between this embodiment and embodiment 1 is that no sealing ring is provided, and the cooperation between the circumferential stopper protrusion and the inversion edge is used to avoid impurities from the inversion edge and the inversion edge. The gaps between the circumferential stop protrusions enter the inner cavity of the protective sleeve connector.

specific Embodiment 4

[0082] Embodiment 4 of the connector assembly of the present application: The difference between this embodiment and Embodiment 1 is that the sealing ring receiving groove is arranged on the inversion edge, and the sealing ring can be prevented from coming out by means of gluing or the like. For another example, the sealing ring can be replaced by an annular sealing gasket (with a rectangular cross-section), and at this time, the sealing ring receiving groove may not be provided. As another example, the sealing ring can be replaced by sealing packing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com