Hollow Shaft Permanent Magnet Traction Motor Stator and Rotor Assembly Method and Device

A traction motor and hollow shaft technology, which is used in electromechanical devices, centering/balancing rotors, manufacturing motor generators, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

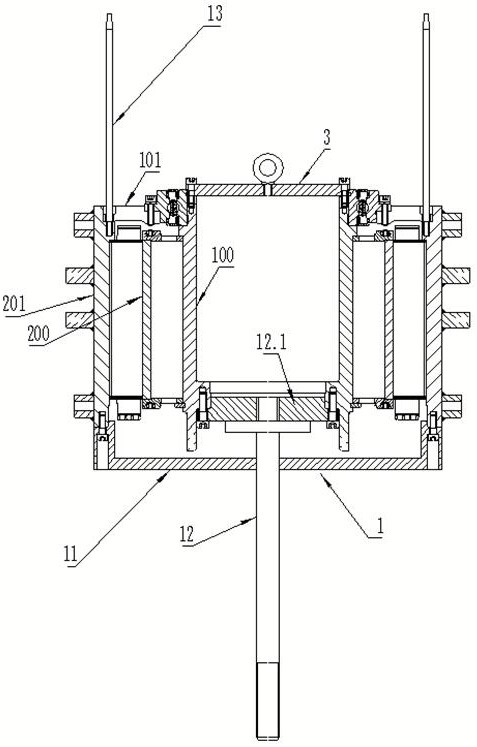

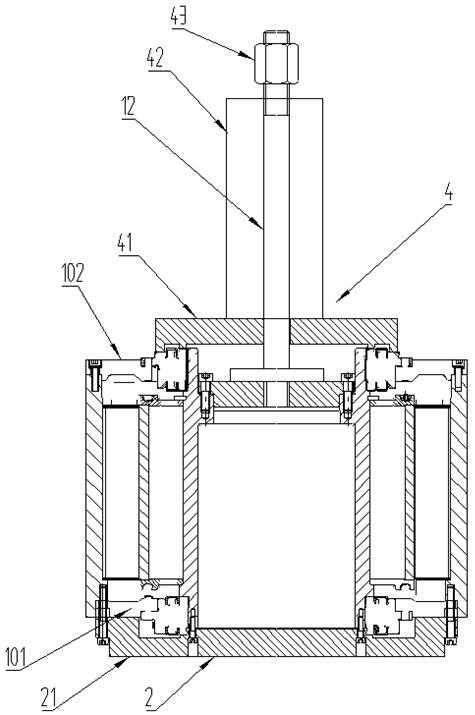

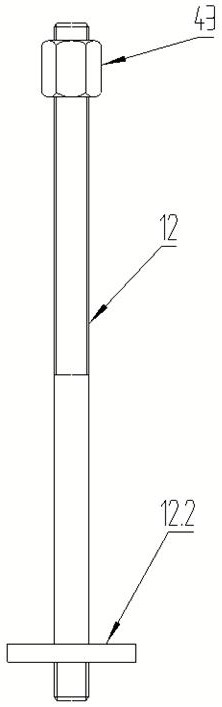

[0029] Combine below Figure 1 to Figure 4 The embodiments of the present invention will be described in detail.

[0030]The method for assembling the stator and the rotor of the permanent magnet traction motor with a hollow shaft at the wheel side is characterized in that firstly, the assembly of the non-transmission end bearing and the non-transmission end end cover 101 is press-fitted to the non-transmission end of the rotor 100 by means of shrink fit. On the corresponding bearing gear; then install the guide assembly 1 for combined guide on the rotor 100 and the stator 200 with the frame 201, and then combine the rotor 100 with the transmission end downward into the stator 200 by lifting and lowering, And in the process of assembly, use the guide assembly 1 to guide until the assembly is in place; then use the connecting assembly 2 to connect the non-transmission end of the rotor 100 and the stator 200 into one, and then turn 180 degrees to adjust the transmission end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com