Application of a glass bottle cold end spraying device

A technology for spraying devices and glass bottles and cans, which is applied in spraying devices, liquid spraying devices, spray booths, etc. It can solve the problems of spraying liquid into glass bottles, etc., and achieve the effects of improving spraying effects, avoiding collisions, and realizing automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

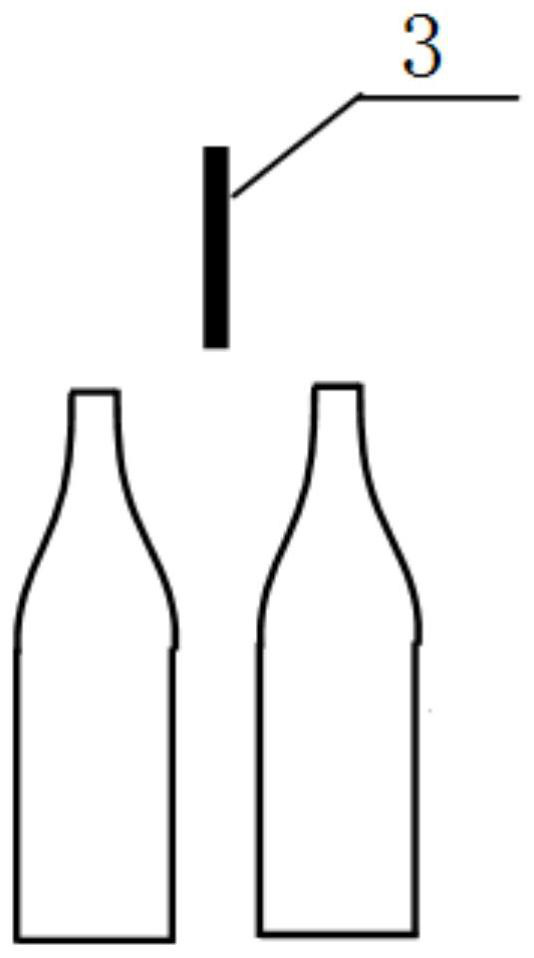

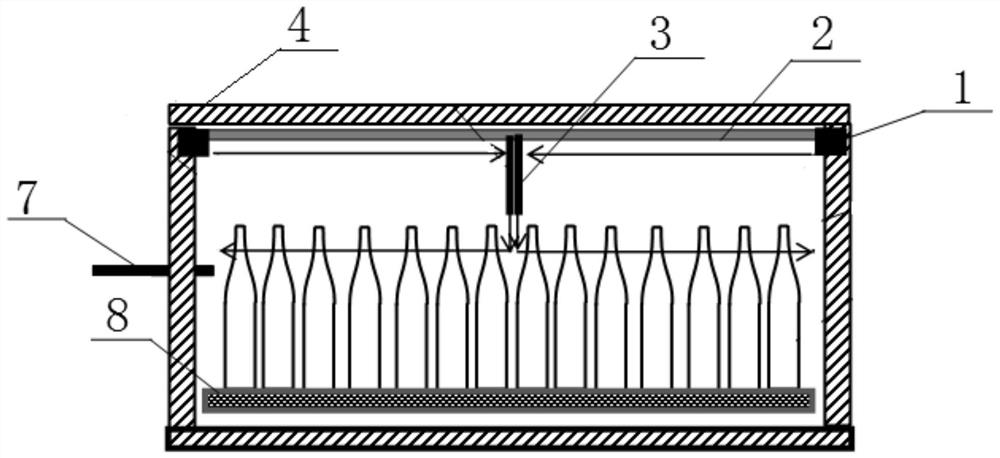

[0032] Such as Figure 1-3 As shown, this embodiment provides a cold-end spraying device for glass bottles and cans, which includes a slide rail 1, a spray gun track 2, a spray gun 3, and a liquid tank. 1. There is a spray gun track 2 in the middle of the two slide rails 1. The two ends of the spray gun track 2 are installed on the slide rail 1 through the driving wheel A. Two spray guns 3 are arranged on the lower side of the spray gun track 2. The upper end of the spray gun 3 is connected to the The spray gun track 2 and the spray gun 3 are connected to the liquid tank through the hydraulic pump, and the initial positions of the two spray guns 3 are set in the middle of the spray gun track 2 .

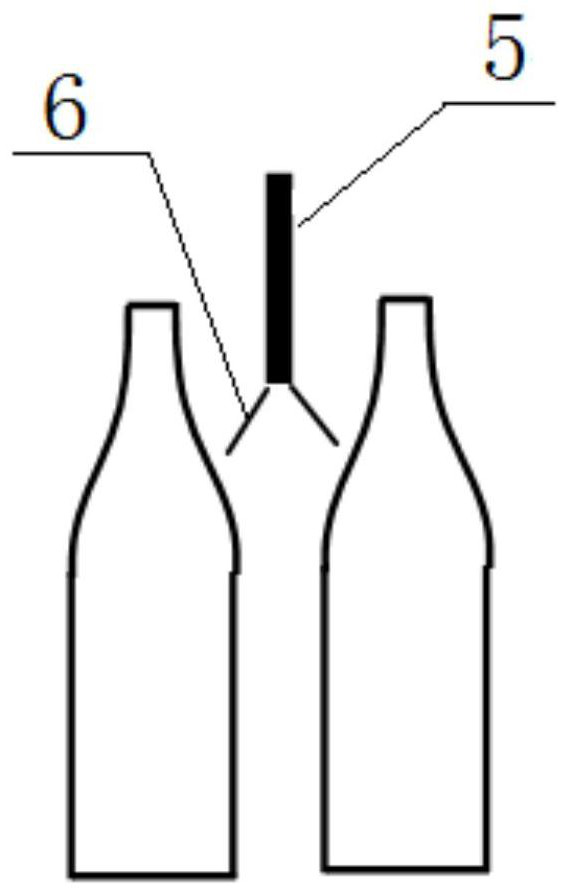

[0033] The spray gun 3 includes an electric push rod 5 and a spray head 6. One end of the electric push rod 5 is connected to the spray gun track 2 through the driving wheel B. The other end of the electric push rod 5 is equipped with a spray head 6. The spray head 6 is connected to ...

Embodiment 2

[0035] A cold-end spraying device for glass bottles and cans, the structure of which is shown in Example 1, the difference is that the spray head 6 is a rotary spray head, so that the spray liquid is more evenly distributed on the surface of the glass bottle.

Embodiment 3

[0037] A cold-end spraying device for glass bottles and cans, the structure of which is shown in Embodiment 1, the difference is that a photoelectric sensor 7 is arranged on the side of the entrance of the confined space, and the height of the glass bottle and the time of entering the confined space are detected by the photoelectric sensor 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com